Big discounting Lsr Silicone Molding - Best China Injection Molding Service – FCE Detail:

Engineering Expertise and Guidance

Engineering team will help you on optimize molding part design, GD&T check, material selection. 100% ensure the product with high production feasibility, quality, traceability

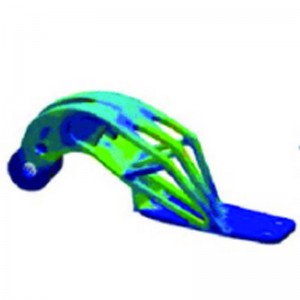

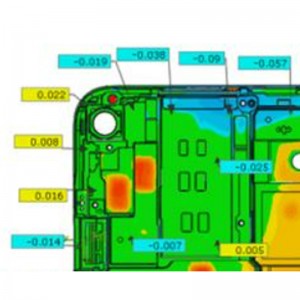

Simulation before Cutting Steel

For each projection, we will use mold-flow, Creo, Mastercam to simulate the injection molding process, machining process, drawing process to predict the issue before make physical samples

Precise Complex Product Manufacturing

We have the top brand manufacturing facilities in injection molding, CNC machining and sheet metal fabrication. Which allows complex, high precision requirement product design

In house process

Injection mold making, Injection molding and second process of pad printing, heat staking, hot stamping, assembly are all in house, so you will have much low cost and reliable development lead time

Available Process

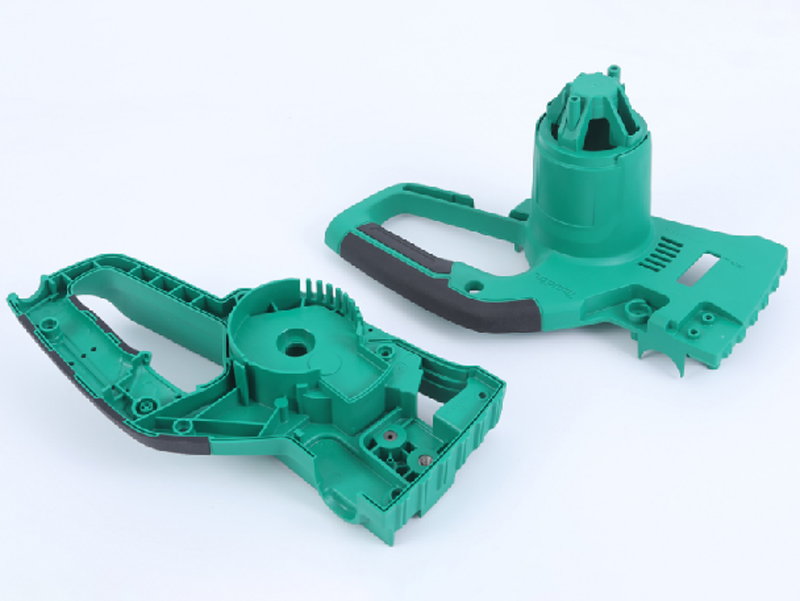

Overmolding

Overmolding is also called as multi-k injection molding. is a unique process that combines two or multiple materials, colors together. It is a best way to achieve multi-color, multi-hardness, multi-layer & touch feeling product. Also be used on single shot have limit that could not achieved product.

Overmolding

Overmolding is also called as multi-k injection molding. is a unique process that combines two or multiple materials, colors together. It is a best way to achieve multi-color, multi-hardness, multi-layer & touch feeling product. Also be used on single shot have limit that could not achieved product.

Liquid Silicone Rubber injection molding

Liquid Silicone Rubber (LSR) is high precision Silicone manufacturing method. And it is only way to have very clear (transparent) rubber part. Silicone part is durable at even 200degree temp. chemical resistance, food grade material.

In mold decoration

In mold decoration (IMD) is a simple and efficient process. Decoration is done inside of the mold without any pre / secondary process. Decoration is completed, including hard coat protection, with just a single shot molding. Allow product have custom patterns, gloss and colors.

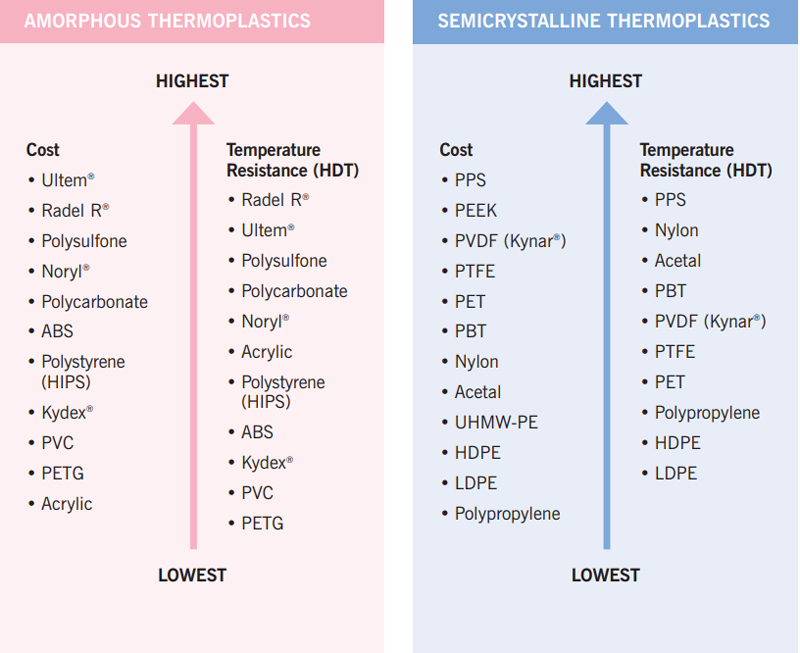

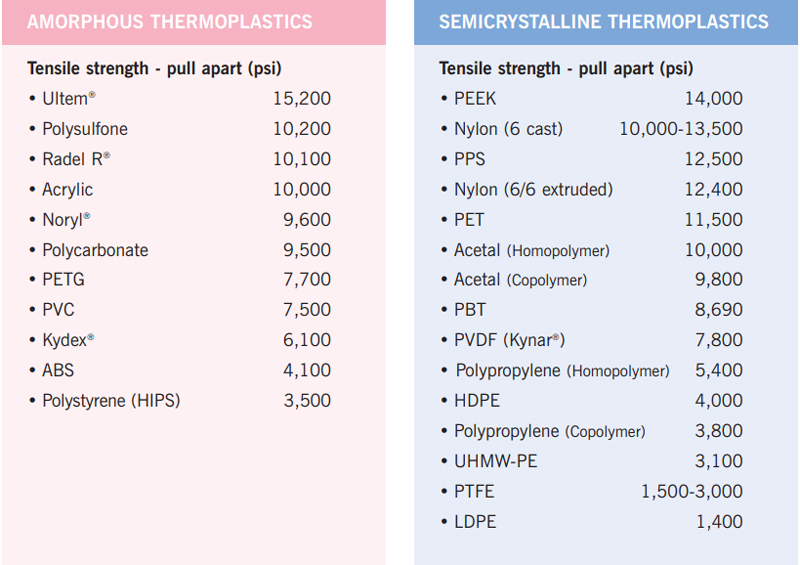

Material Selection

FCE will help you find best material according to the product requirement and application. There is a lot of choices in the market, we will also according the cost effective and supply chain stability to recommend the brand and grade of resins.

Molded part Finishes

| Glossy | Semi-Glossy | Matte | Textured |

| SPI-A0 | SPI-B1 | SPI-C1 | MT (Moldtech) |

| SPI-A1 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| SPI-A2 | SPI-B3 | SPI-C3 | YS (Yick Sang) |

| SPI-A3 |

Plastic Injection Molding Capabilities

Secondary Processes

Heat Staking

Heat and Press metal inserts or other stiff material part into the product. After the melt material get solid, they are bonded together. Typical for the brass thread nuts.

Laser Engraving Mark the patterns onto the product with laser. With laser sensitive material, we can have white laser mark on the black part.

Pad Printing/screen printing

Print ink onto the product surface, multi-color overprinting is accepted.

NCVM and Painting To have different color, roughness, metallic effect and anti-scratch surface effect. Typically for the cosmetic products.

Ultrasonic Plastic Welding

Joint two part with Ultrasonic energy, cost effective, good seal and cosmetic.

FCE Injection molding solutions

From concept to reality

Prototype tool

For quick design verification with real material and process, Fast prototype steel tooling is a good solution for it. It could be bridge of production also.

- No minimum order limit

- Complex design achievable

- 20k shot tool life guaranteed

Production tooling

Normally with hard steel, hot runner system, hard steel. Tool life is about 500k to 1million shots. Unit product price is very low, but mold cost is higher than the prototype tool

- Over 1 million shots

- High efficiency & running cost

- High product quality

Typical Development Process

Quote with DFx

Check you requirement data and applications, provide scenarios quote with different suggestions. Simulation report with be provided in parallel

Review prototype (alternative)

Develop rapid tool (1~2wks) to mold prototype samples for design and molding process verification

Production mold development

You can kick off ramp up immediately with prototype tool. If the demand over millions, kick off production mold with multi-cavitation in parallel, which will take approx. 2~5weeks

Repeat Order

If you have focus for the demand, we can start delivery within 2days. No focus order, we can start partial shipment as few as 3days

Q&A

What is injection molding?

Injection molding is two large metal mold halves coming together, a plastic or rubber material is injected into the cavity. The plastic materials being injected are melted, they aren’t really heated; The material is pressed into the injection via the runner gate. As the material is compressed, it heats and begins to flow into the molds. Once it cools, the two halves separate again and the part come out. Repeat same actions from closing mold and open mold as one circle, and you have a run of injection molded parts ready.

What industries use injection molding?

Variety fields can used in the followings:

Medical & Pharmaceutical

Electronics

Construction

Food & Beverage

Automotive

Toys

Consumer Goods

Household

What are the types of injection molding processes?

There are several types of injection molding processes, including:

Custom plastic injection molding

Overmolding

Insert molding

Gas-assisted injection molding

Liquid silicone rubber injection molding

Metal injection molding

Reaction injection molding

How long does an injection mold last?

Depends on several factors: mold material, number of cycles, operating conditions, and cooling/holding pressure time between production runs.

What is the difference between forming and molding?

Although quite similar, the difference between forming and molding comes down to their unique features and benefits, depending on the application they are being used for. Injection molding is more suitable for large production runs. Thermoforming, is more suitable for shorter production runs of large designs and involves forming heated plastic sheets to the mold’s surface.

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for Big discounting Lsr Silicone Molding - Best China Injection Molding Service – FCE , The product will supply to all over the world, such as: United Arab emirates, Turin, Ukraine, Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

We have been looking for a professional and responsible supplier, and now we find it.