factory customized Mold Processing - Box Build Services and Processes – FCE Detail:

Development, Production, and Product Life Management Made Easy

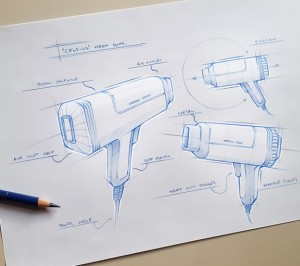

Thoughtful ideation and professional industrial design.

Mechanical engineering, electrical engineering, and comprehensive DFM.

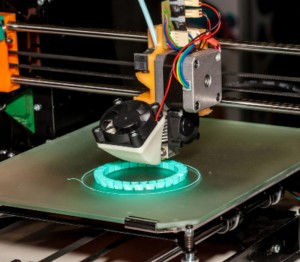

Rapid prototyping with proper and Economic materials and processes.

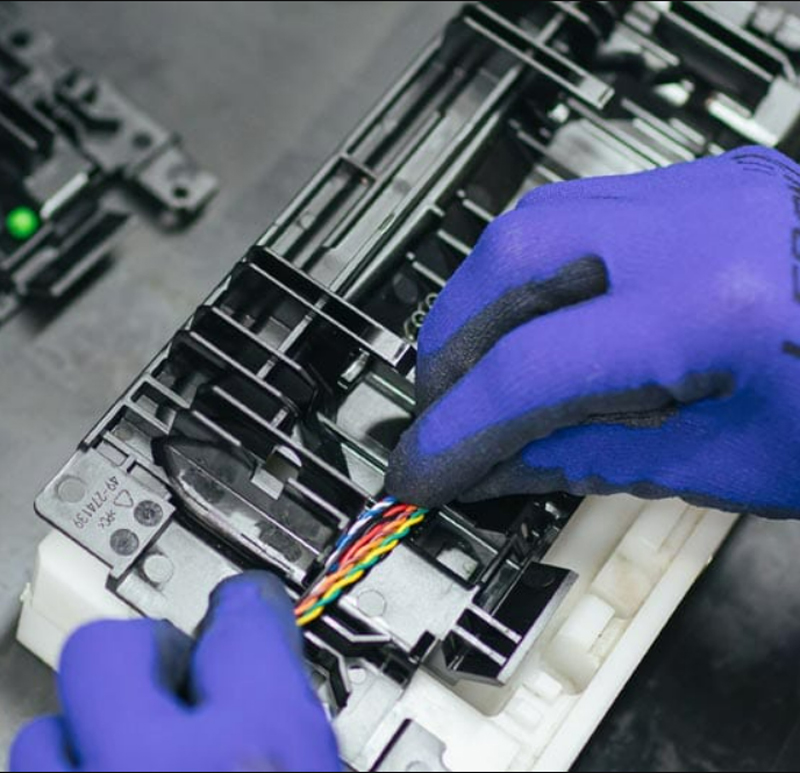

Reliable manufacturing from parts to complete box build.

FCE Box Build Service

In FCE, We deliver a one station end-to-end service, with the resources to handle large-scale projects, combined with flexibility and attention to details.

- Injection molding, machining, sheet metal and rubber parts in house production

- Printed circuit board assembly

- Product Assembly

- System Level Assembly

- Testing of ICT (In-Circuit Test), Functional, Final, Environmental and Burn-In

- Software Loading and Product Configuration

- Warehousing & Order Fulfillment & Traceability

- Packaging & Labeling including Bar Coding

- Aftermarket Service

Contract Manufacture Facility overview

At FCE, In house injection molding, custom machining, sheet metal fabrication and PCBA manufacture ensured the fast, succussed and cost-effective project development. Integrated resources help custom get all of support from one contact window.

Injection molding workshop

Machining workshop

Sheet metal workshop

SMT production line

System assembly line

Packing & Warehousing

General FAQs

What is Box Build Assembly?

A Box Build Assembly is also as known of Systems Integration. The assembly work involved in electromechanical assembly process, which includes enclosure manufacturing, PCBA installation, sub-assembling and components mounting, cabling, and wire harness assembly. FCE Box Build offers product solutions ranging from reliable and affordable part production to comprehensive end-to-end program management. Whether you need to make a single part or a complete finish product in retail packaging, we have your solution

What info. Are needed for contract manufacturing quotation?

(a) Product dimensions

(b) Bill of Materials

(c) 3D Cad Model

(d) Quantities needed

(e) Packaging required

(f) Shipping Address

Do you provide ODM service?

FCE design center and a cooperated outsource design firm could finish most of medical, industrial and consumer products. Whenever you got a idea, contact us to see if we can support you to reality your thought. FCE will tailor the design and production base on your budget.

Available Materials for sheet metal fabrication

FCE prepared 1000+ common sheet material in stock for fastest turnaround, Our mechanical engineering will help you on material selection, mechanical analysis, feasibility optimizations

| Aluminum | Copper | Bronze | Steel |

| Aluminum 5052 | Copper 101 | Bronze 220 | Stainless Steel 301 |

| Aluminum 6061 | Copper 260 (Brass) | Bronze 510 | Stainless Steel 304 |

| Copper C110 | Stainless Steel 316/316L | ||

| Steel, Low Carbon |

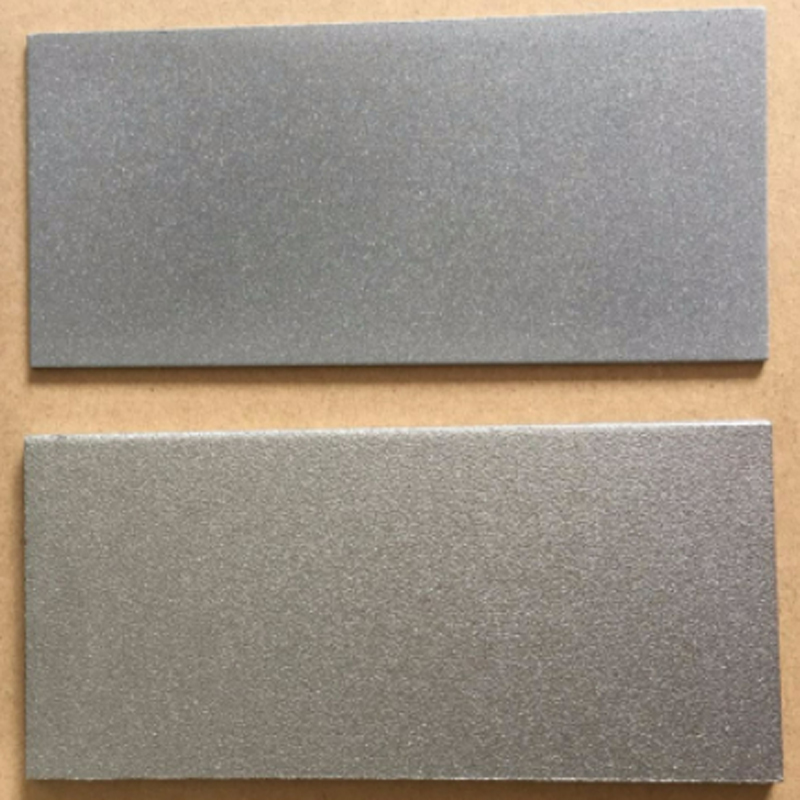

Surface Finishes

FCE offers a complete range of surface treatment processes. Electroplating, powder coating, anodizing can be customized according to color, texture and brightness. The appropriate finish can also be recommended according to functional requirements.

Brushing

Blasting

Polishing

Anodizing

Powder Coating

Hot Transfer

Plating

Printing & Laser Mark

Our Quality Promise

Product detail pictures:

Related Product Guide:

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto High High quality, Competitive Rate, Fast Service for factory customized Mold Processing - Box Build Services and Processes – FCE , The product will supply to all over the world, such as: Russia, Serbia, Las Vegas, At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.