Sabis ɗin Gyaran allura

Kwarewar Injiniya da Jagora

Teamungiyar injiniya za ta taimaka muku akan haɓaka ƙirar ɓangaren gyare-gyare, duba GD&T, zaɓin kayan. 100% tabbatar da samfurin tare da yuwuwar samarwa, inganci, ganowa

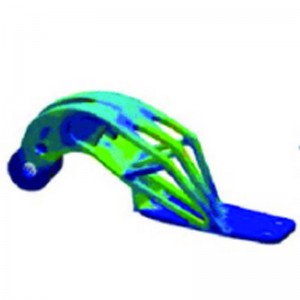

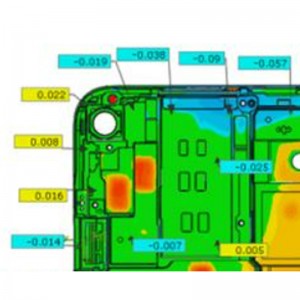

Simulation kafin Yanke Karfe

Ga kowane tsinkaya, za mu yi amfani da mold-flow, Creo, Mastercam don yin kwatankwacin tsarin gyare-gyaren allura, aikin injin, tsarin zane don hango hasashen batun kafin yin samfuran jiki.

Madaidaicin Haɗaɗɗen Samfura

Muna da manyan wuraren masana'anta a cikin gyare-gyaren allura, injinan CNC da ƙirar ƙarfe. Wanne damar hadaddun, babban madaidaicin ƙira samfurin

A cikin tsarin gida

Yin gyare-gyaren allura, gyare-gyaren allura da kuma tsari na biyu na bugu na pad, zafi stamping, zafi stamping, taro duk suna cikin gida, don haka za ku sami ƙarancin farashi da ingantaccen lokacin jagorar ci gaba.

Tsari mai samuwa

Overmolding

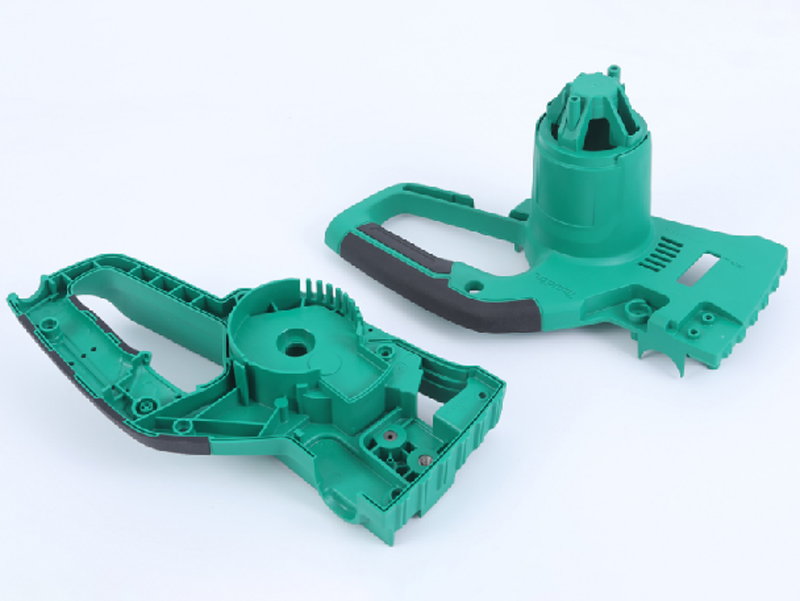

Ana kuma kiran overmolding azaman gyare-gyaren allura da yawa. wani tsari ne na musamman wanda ya haɗa abubuwa biyu ko yawa, launuka tare. Hanya ce mafi kyau don cimma samfura masu launuka iri-iri, tauri, multi-layer & taba ji. Hakanan ana amfani dashi akan harbi ɗaya yana da iyaka wanda ba zai iya cimma samfurin ba.

Overmolding

Ana kuma kiran overmolding azaman gyare-gyaren allura da yawa. wani tsari ne na musamman wanda ya haɗa abubuwa biyu ko yawa, launuka tare. Hanya ce mafi kyau don cimma samfura masu launuka iri-iri, tauri, multi-layer & taba ji. Hakanan ana amfani dashi akan harbi ɗaya yana da iyaka wanda ba zai iya cimma samfurin ba.

Liquid Silicone Rubber gyare-gyaren allura

Liquid Silicone Rubber (LSR) shine babban madaidaicin hanyar masana'anta Silicone. Kuma hanya ce kawai don samun ɓangaren roba bayyananne (m). Bangaren silicone yana da ɗorewa a ko da 200 digiri. sinadaran juriya, kayan abinci.

A cikin kayan ado

A cikin kayan ado na mold (IMD) tsari ne mai sauƙi da inganci. Ana yin ado a cikin ƙirar ba tare da wani tsari na gaba / sakandare ba. An kammala kayan ado, gami da kariyar gashi mai wuya, tare da gyare-gyaren harbi guda ɗaya kawai. Bada samfurin ya sami alamu na al'ada, mai sheki da launuka.

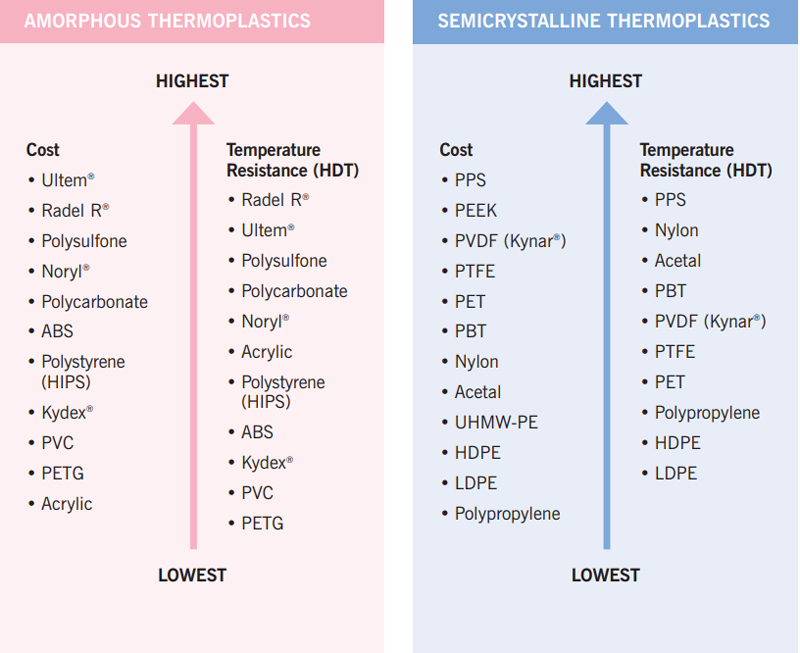

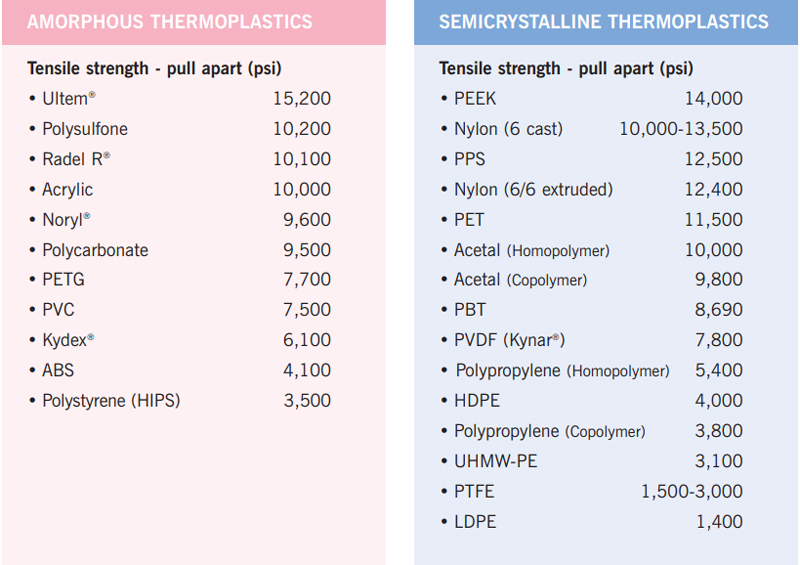

Zaɓin kayan aiki

FCE zai taimake ku nemo mafi kyawun abu bisa ga buƙatun samfur da aikace-aikacen. Akwai zaɓuɓɓuka da yawa a kasuwa, za mu kuma bisa ga ingancin farashi da kwanciyar hankali na samar da kayayyaki don ba da shawarar alama da darajar resins.

Bangaren da aka ƙera ya ƙare

| Mai sheki | Semi-mai sheki | Matte | Rubutun rubutu |

| SPI-A0 | SPI-B1 | SPI-C1 | MT (Moldtech) |

| SPI-A1 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| SPI-A2 | SPI-B3 | SPI-C3 | YS (Yick Sang) |

| SPI-A3 |

Ƙarfin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara

Tsarin Sakandare

Heat Staking

Zafi da Latsa abubuwan ƙarfe na ƙarfe ko wani ɓangaren abu mai tauri a cikin samfurin. Bayan kayan narkewa sun yi ƙarfi, an haɗa su tare. Na al'ada ga ƙwayayen zaren tagulla.

Zane Laser Yi alama akan samfurin tare da Laser. Tare da Laser m abu, za mu iya samun farin Laser alama a kan baki part.

Buga Pad/Buga allo

Buga tawada akan saman samfurin, ana karɓar bugu mai yawa.

NCVM da Painting Don samun launi daban-daban, roughness, ƙarfin ƙarfe da tasirin anti-scratch. Yawanci don samfuran kwaskwarima.

Ultrasonic Plastic Welding

Haɗin gwiwa kashi biyu tare da makamashin Ultrasonic, tasiri mai tsada, hatimi mai kyau da kayan kwalliya.

FCE Injection gyare-gyaren mafita

Daga ra'ayi zuwa gaskiya

Kayan aikin samfuri

Don tabbatar da ƙira da sauri tare da ainihin abu da tsari, Saurin samfur na kayan aiki na ƙarfe shine mafita mai kyau a gare shi. Yana iya zama gadar samarwa kuma.

- Babu mafi ƙarancin oda

- Zane mai rikitarwa mai yiwuwa

- 20k harbi kayan aiki rai garanti

Kayan aikin samarwa

Yawanci tare da ƙarfe mai ƙarfi, tsarin mai gudu mai zafi, ƙarfe mai ƙarfi. Rayuwar kayan aiki tana kusan harbin 500k zuwa miliyan 1. Farashin samfurin raka'a yana da ƙasa sosai, amma farashin ƙira ya fi kayan aikin samfur girma

- Fiye da harbe-harbe miliyan 1

- Babban inganci & tsadar gudu

- Babban ingancin samfur

Tsarin Ci Gaba Na Musamman

Magana tare da DFx

Bincika bayanan buƙatun ku da aikace-aikace, samar da fa'idodin yanayi tare da shawarwari daban-daban. Rahoton kwaikwayo tare da bayar da shi a layi daya

Nau'in bita (madadin)

Haɓaka kayan aiki mai sauri (1 ~ 2wks) don ƙirƙirar samfuran samfuri don ƙira da tabbatar da tsari

Samar da mold ci gaban

Kuna iya kunna hawan hawan kai tsaye tare da kayan aikin samfuri. Idan bukatar a kan miliyoyin, kaddamar da samar mold tare da Multi-cavitation a layi daya, wanda zai dauki kimanin. 2 ~ 5 makonni

Maimaita oda

Idan kun mai da hankali ga buƙatu, za mu iya fara bayarwa a cikin kwanaki 2. Babu odar mayar da hankali, za mu iya fara jigilar kaya kaɗan kaɗan kamar kwanaki 3

Tambaya&A

Menene gyaran allura?

Yin gyare-gyaren allura shine manyan ɓangarorin ƙarfe guda biyu suna haɗuwa tare, ana yin allurar filastik ko roba a cikin rami. Ana narkar da kayan filastik da ake yi wa allurar, ba su da zafi sosai; Ana danna kayan a cikin allura ta ƙofar mai gudu. Yayin da aka matsa kayan, yana zafi kuma ya fara gudana a cikin gyare-gyare. Da zarar ya huce, rabi biyun kuma suka sake rabuwa sannan sashin ya fito. Maimaita ayyuka iri ɗaya daga rufe mold da buɗaɗɗen ƙira a matsayin da'irar ɗaya, kuma kuna da shirye-shiryen gyare-gyaren allura.

Wadanne masana'antu ke amfani da gyare-gyaren allura?

Ana iya amfani da filaye iri-iri a cikin masu zuwa:

Medical & Pharmaceutical

Kayan lantarki

Gina

Abinci & Abin sha

Motoci

Kayan wasan yara

Kayayyakin Mabukaci

Gidan gida

Menene nau'ikan hanyoyin gyaran allura?

Akwai nau'ikan hanyoyin gyaran allura da yawa, gami da:

Canjin alluran filastik na al'ada

Overmolding

Saka gyare-gyare

Gyaran allura mai taimakon gas

Liquid silicone roba allura gyare-gyare

Ƙarfe gyare-gyare

Reaction allura gyare-gyare

Har yaushe ne maganin allura zai kasance?

Ya dogara da abubuwa da yawa: kayan ƙira, adadin zagayowar, yanayin aiki, da sanyaya/riƙe lokacin matsa lamba tsakanin ayyukan samarwa.

Menene bambanci tsakanin kafa da gyare-gyare?

Ko da yake yayi kama da haka, bambanci tsakanin ƙirƙira da gyare-gyare yana zuwa ga keɓantattun siffofi da fa'idodin su, ya danganta da aikace-aikacen da ake amfani da su. Yin gyaran allura ya fi dacewa da manyan ayyukan samarwa. Thermoforming, ya fi dacewa da gajerun hanyoyin samar da manyan kayayyaki kuma ya haɗa da ƙirƙirar zanen filastik masu zafi zuwa saman ƙirar.