Saka Molding

Kwarewar Injiniya da Jagora

Teamungiyar injiniya za ta taimaka muku akan haɓaka ƙirar ɓangaren gyare-gyare, duba GD&T, zaɓin kayan. 100% tabbatar da samfurin tare da yuwuwar samarwa, inganci, ganowa

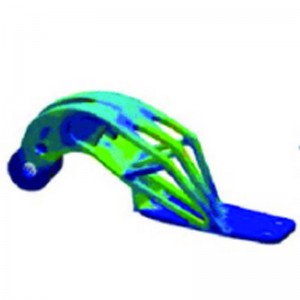

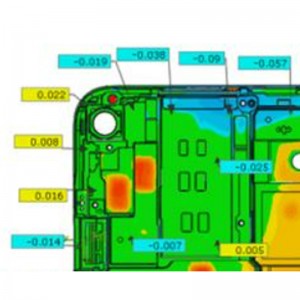

Simulation kafin Yanke Karfe

Ga kowane tsinkaya, za mu yi amfani da mold-flow, Creo, Mastercam don yin kwatankwacin tsarin gyare-gyaren allura, aikin injin, tsarin zane don hango hasashen batun kafin yin samfuran jiki.

Madaidaicin Haɗaɗɗen Samfura

Muna da manyan wuraren masana'anta a cikin gyare-gyaren allura, injinan CNC da ƙirar ƙarfe. Wanne damar hadaddun, babban madaidaicin ƙira samfurin

A cikin tsarin gida

Yin gyare-gyaren allura, gyare-gyaren allura da kuma tsari na biyu na bugu na pad, zafi stamping, zafi stamping, taro duk suna cikin gida, don haka za ku sami ƙarancin farashi da ingantaccen lokacin jagorar ci gaba.

Saka Molding

Saka gyare-gyare tsari ne na gyare-gyaren allura wanda ke amfani da ƙulla wani abu a cikin ɓangaren filastik. Tsarin ya ƙunshi matakai biyu masu mahimmanci.

Da fari dai, ana shigar da abin da aka gama a cikin ƙirar kafin aiwatar da gyare-gyaren a zahiri. Abu na biyu, ana zubar da kayan filastik da aka narkar da su a cikin kwano; yana ɗaukar siffar sashi da haɗin gwiwa tare da ɓangaren da aka ƙara a baya.

Za a iya yin gyare-gyaren gyare-gyare tare da nau'i-nau'i iri-iri, kayan za su kasance kamar:

- Karfe fasteners

- Tubes da studs

- Abun ciki

- Abubuwan lantarki

- Takamaimai, kayan ado, da sauran abubuwan ado

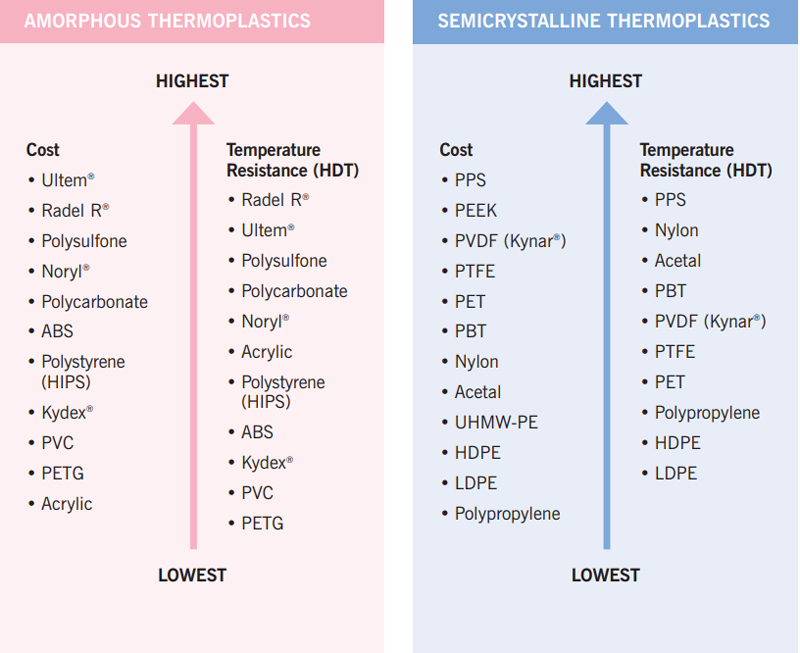

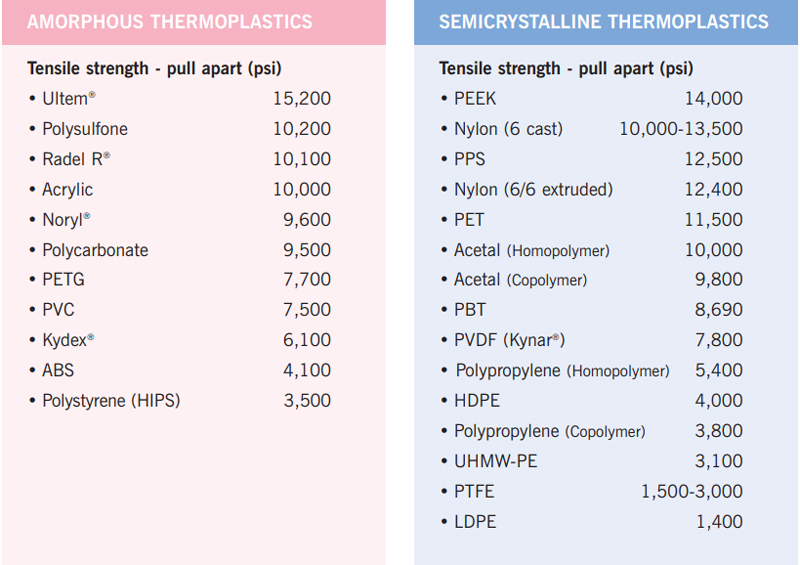

Zaɓin kayan aiki

FCE zai taimake ku nemo mafi kyawun abu bisa ga buƙatun samfur da aikace-aikacen. Akwai zaɓuɓɓuka da yawa a kasuwa, za mu kuma bisa ga ingancin farashi da kwanciyar hankali na samar da kayayyaki don ba da shawarar alama da darajar resins.

Bangaren da aka ƙera ya ƙare

| Mai sheki | Semi-mai sheki | Matte | Rubutun rubutu |

| SPI-A0 | SPI-B1 | SPI-C1 | MT (Moldtech) |

| SPI-A1 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| SPI-A2 | SPI-B3 | SPI-C3 | YS (Yick Sang) |

| SPI-A3 |

Yana Haɓaka Zane

Saka gyare-gyare yana bawa masu ƙira da masana'anta damar yin kusan kowace irin siffa ko ƙira da suke so

Rage Tattalin Arziki da Ma'aikata

Haɗa daban-daban sassa daban-daban zuwa gyare-gyaren allura guda ɗaya, yin ƙarin farashi mai inganci. Tare da saka gyare-gyaren zama tsari na mataki ɗaya, rage girman matakan taro da farashin aiki

Yana ƙara dogaro

Narkar da filastik yana gudana cikin yardar kaina a kusa da kowane abin da aka saka kafin sanyaya da saitin dindindin, an saka shi da ƙarfi a cikin filastik

Yana Rage Girma da Nauyi

Saka gyare-gyare yana haifar da sassan filastik waɗanda suka fi ƙanƙanta da nauyi a nauyi, duk da kasancewa mafi aiki da aminci fiye da sassan filastik da aka yi tare da wasu hanyoyin.

Kayayyaki iri-iri

Saka gyare-gyare wani tsari ne wanda zai iya amfani da nau'ikan resin filastik daban-daban, kamar babban aikin thermoplastics

Daga Prototype zuwa Production

Rapid Design Molds

Hanyar da ake tsammani don ingantaccen ƙirar ƙira, ƙarancin tabbaci, matakan samarwa

- Babu ƙarancin ƙima mai iyaka

- Ƙirar ƙirar ƙira mai dacewa

- An karɓi ƙira mai rikitarwa

Kayan Aikin Kaya

Mafi dacewa don sassan samar da ƙara, farashin kayan aiki ya fi Rapid Design Molds, amma yana ba da damar rage farashin sashe.

- Har zuwa 5M harbin gyare-gyare

- Multi-rago kayan aiki

- Atomatik da saka idanu

Tsarin Ci Gaba Na Musamman

Magana tare da DFx

Bincika bayanan buƙatun ku da aikace-aikace, samar da fa'idodin yanayi tare da shawarwari daban-daban. Rahoton kwaikwayo tare da bayar da shi a layi daya

Nau'in bita (madadin)

Haɓaka kayan aiki mai sauri (1 ~ 2wks) don ƙirƙirar samfuran samfuri don ƙira da tabbatar da tsari

Samar da mold ci gaban

Kuna iya kunna hawan hawan kai tsaye tare da kayan aikin samfuri. Idan bukatar a kan miliyoyin, kaddamar da samar mold tare da Multi-cavitation a layi daya, wanda zai dauki kimanin. 2 ~ 5 makonni

Maimaita oda

Idan kun mai da hankali ga buƙatu, za mu iya fara bayarwa a cikin kwanaki 2. Babu odar mayar da hankali, za mu iya fara jigilar kaya kaɗan kaɗan kamar kwanaki 3

Saka FAQs Molding

Saka aikace-aikacen gyare-gyare

- Knobs don kayan aiki, sarrafawa da majalisai

- Na'urorin lantarki da aka haɗa da kayan lantarki

- Zaren sukurori

- Rushewar bushings, tubes, studs, da aka buga

- Na'urorin likitanci da kayan aiki

Menene Bambanci Tsakanin Saka Molding & Overmolding

Saka gyare-gyare ɗaya ne daga cikin hanyoyin da ake amfani da su don ƙera robobi a kusa da abin da ba na filastik ba.

A cikin sauƙi mai sauƙi, babban bambanci shine yawan matakan da ake buƙata don cimma sakamakon ƙarshe.

A gefe guda, Saka gyare-gyare yana yin abu ɗaya, amma a mataki ɗaya kawai. Bambanci ya ta'allaka ne akan hanyar da aka yi samfurin ƙarshe. Anan, abubuwan da aka saka da narkakkar suna cikin injin don samar da samfurin haɗe na ƙarshe.

Wani babban bambance-bambancen shine cewa saka gyare-gyare ba a daure shi da filastik ba, gami da karafa tare da samfura daban-daban

Yawanci ana amfani da overmolding don samar da samfura masu kyaun laushi, siffa, da launuka, galibi an yi su don roƙon shiryayye. Ana amfani da saka gyare-gyaren don ƙirƙirar samfura masu tsauri.