A cikin Mold Decoration

CNC Machining Akwai Tsari

Ƙwararrun Ƙwararru da Jagora

Ƙwararrun ƙwararrun ƙungiyar za su taimaka muku akan haɓaka ƙirar gyare-gyare, ingantaccen samfuri, shawarwarin kowane fim ko haɓaka ƙira da aikace-aikacen samarwa.

Samfuran Dubawa Akwai

Kayan aikin matakin samarwa yana samuwa tare da samfuran T1 waɗanda aka kawo a cikin makonni 3

Karɓar Ƙirƙirar Ƙira

Ƙunƙarar haƙuri da karɓar zane na 2D don tabbatar da dacewa sosai tare da buƙatun da kuke so tare da adana farashi amma ingancin inganci

IMD Sub Tsarin

IML-In Mold Label

IML wata dabara ce wacce ake shigar da lakabin da aka riga aka buga a cikin wani mold nan da nan kafin yin gyare-gyare. Ta wannan hanyar, ana iya samar da cikakkun sassan da aka buga a ƙarshen aikin gyare-gyaren, ba tare da buƙatar ƙarin wahala da tsadar bugu ba.

IMF-In Mold Film

Kusan iri ɗaya ne da IML amma galibi ana amfani dashi don sarrafa 3D akan saman IML. Tsarin: Buga → kafawa → naushi → alluran filastik na ciki. An yadu amfani da gyare-gyare ga PC injin da kuma high matsa lamba, da yawa dace da high tensile kayayyakin, 3D kayayyakin.

IMR-In Mold Roller

IMR wani tsari ne na IMD don canja wurin hoto a ɓangaren. Matakan tsari: an aika fim ɗin a cikin ƙirar kuma an sanya shi, sa'an nan kuma an canza zane zuwa samfurin allura bayan rufe samfurin. Bayan buɗe samfurin, an cire fim ɗin kuma an fitar da samfurin.

Fasaha: saurin samarwa da sauri, barga yawan amfanin ƙasa, ƙarancin farashi, daidai da canjin masana'antar 3C, buƙatun buƙatun rayuwa. Samfuran aikace-aikacen: wayoyin hannu, kyamarori na dijital da samfuran 3C.

A cikin Tsarin Ado Mold

Rubutun Foil

In-Mold Decoration film ana buga shi ta hanyar babban saurin bugu gravure. Yadudduka da yawa (na musamman) na launi mai hoto (max) kuma ana amfani da Layer na gashi mai wuya da mannewa yayin wannan aikin bugu.

IMD gyare-gyare

An saka mai ciyar da foil akan injin allura. Sannan ana ciyar da fim ɗin foil tsakanin kayan aikin gyaran allura. Na'urori masu auna firikwensin gani a cikin feeder suna daidaita rajistar fim ɗin, kuma tawada da aka buga akan fim ɗin ana canza shi zuwa filastik ta zafi da matsa lamba na gyaran allura.

Samfura

Bayan gyare-gyaren allura, samfuran da aka yi wa ado suna samuwa. Babu buƙatar tsari na 2, sai dai idan an yi amfani da maganin UV na HC, akwai tsarin warkar da UV

Ƙayyadaddun Fasaha

| Hanyar bugawa | Buga Gravure, bugu na siliki |

| Abubuwan da ake buƙata don gyaran allura | ABS, PC, PC, PBT + Gilashin fiber, PET, PC / ABS, PMMA, TPU, da dai sauransu |

| Ƙarshen saman | Babban mai sheki, Mid matte, Low matte, Silky touch, Soft touch |

| Ayyukan saman | Rufi mai wuya (juriya), UV garkuwa, Anti yatsa |

| Sauran ayyuka | Tawada mai isar da saƙon IR, Ƙarƙashin tawada |

| IMD Aikace-aikace | IMD bangarorin biyu, IMD harbi biyu, Saka IMD |

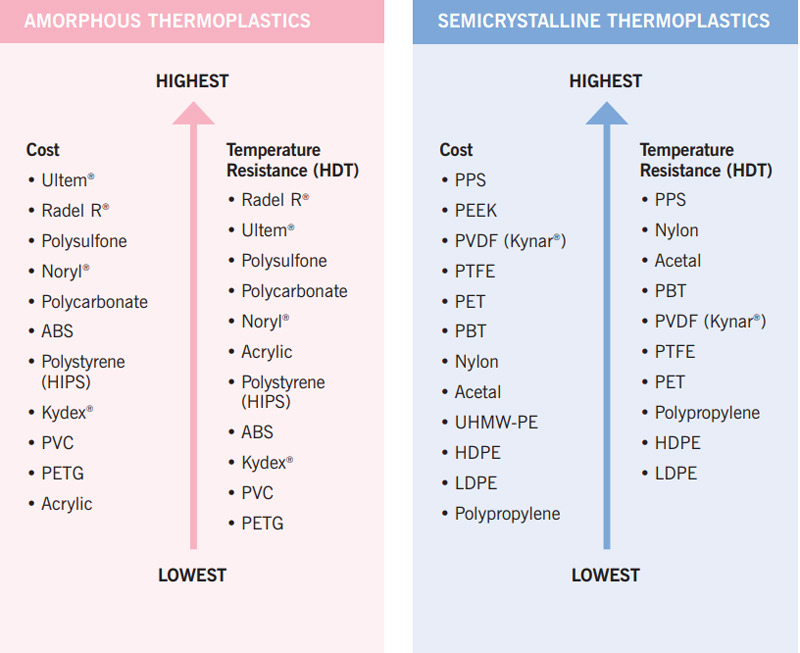

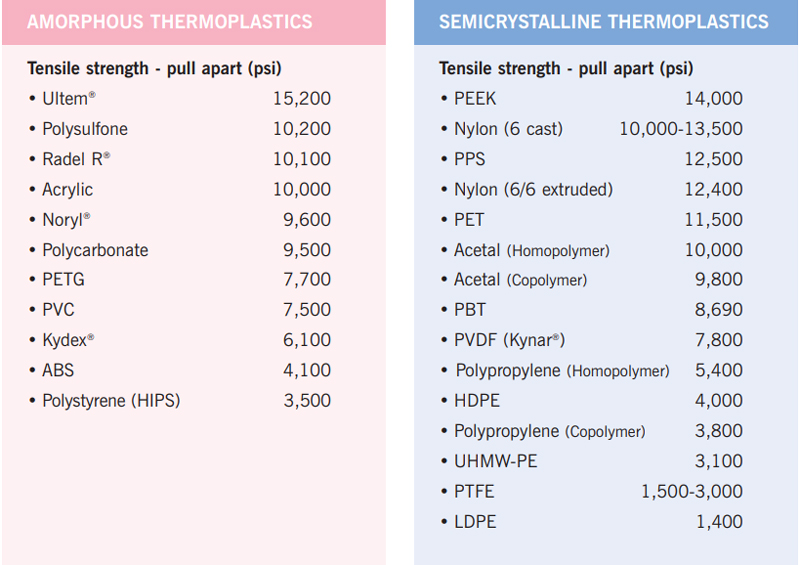

Zaɓin kayan aiki

FCE zai taimake ku nemo mafi kyawun abu bisa ga buƙatun samfur da aikace-aikacen. Akwai zaɓuɓɓuka da yawa a kasuwa, za mu kuma bisa ga ingancin farashi da kwanciyar hankali na samar da kayayyaki don ba da shawarar alama da darajar resins.

Mabuɗin Amfani

Kariyar gashi mai wuya

Tsarin kwaskwarima yana da kariya ga karce, juriya na sinadarai amma tare da shimfida mai launi

Ado on Design Data

Adon saman yana bin bayanan ƙira, tunda ana amfani da kayan ado a lokaci guda na aikin gyaran allura

Daidaitaccen rajista

Daidaitaccen tsarin ciyar da foil tare da firikwensin gani da +/- 0.2mm daidaitaccen iko

Babban aikin nadi tsarin ciyarwa

Fails da gyare-gyaren IMD ana sarrafa su ta tsarin abin nadi. Mota da ingantaccen samarwa

Abokan muhalli

Ana amfani da tawada IMD akan yankin da aka yarda da kayan ado kawai. Ana amfani da abubuwan haɗin sinadarai masu aminci don kare muhalli

Daga Prototype zuwa Production

Rapid Design Molds

Hanyar da ake tsammani don ingantaccen ƙirar ƙira, ƙarancin tabbaci, matakan samarwa

- Babu ƙarancin ƙima mai iyaka

- Ƙirar ƙirar ƙira mai dacewa

- Kayan aiki mai laushi tare da karfe mai wuya

Kayan Aikin Kaya

Mafi dacewa don sassan samar da ƙara, farashin kayan aiki ya fi Rapid Design Molds, amma yana ba da damar rage farashin sashe.

- Har zuwa 5M harbin gyare-gyare

- Multi-rago kayan aiki

- Atomatik da saka idanu

Tsarin Ci Gaba Na Musamman

Magana tare da DFx

Bincika bayanan buƙatun ku da aikace-aikace, samar da fa'idodin yanayi tare da shawarwari daban-daban. Rahoton kwaikwayo tare da bayar da shi a layi daya

Nau'in bita (madadin)

Haɓaka kayan aiki mai sauri (1 ~ 2wks) don ƙirƙirar samfuran samfuri don ƙira da tabbatar da tsari

Samar da mold ci gaban

Kuna iya kunna hawan hawan kai tsaye tare da kayan aikin samfuri. Idan bukatar a kan miliyoyin, kaddamar da samar mold tare da Multi-cavitation a layi daya, wanda zai dauki kimanin. 2 ~ 5 makonni

Maimaita oda

Idan kun mai da hankali ga buƙatu, za mu iya fara bayarwa a cikin kwanaki 2. Babu odar mayar da hankali, za mu iya fara jigilar kaya kaɗan kaɗan kamar kwanaki 3

A cikin Mold Decoration FAQs

Menene fa'idodin A cikin Mold Decoration

- Amfani da yawa sosai

- Yana haifar da rufaffiyar saman gaba ɗaya

- Yana aiki tare da abubuwa da yawa

- Babu buƙatar kammala sakandare

- Za'a iya haɗa manyan abubuwan gamawa, gami da UV-stable

- Yiwuwar haɗa masu sauyawa masu rai

- Babu buƙatar yin lakabin bayan gyare-gyare

- Aiki tare da tabo launi ko cikakken graphics

- Ajiye farashi a cikin kayan gyare-gyare

Menene aikace-aikace na Adon Mold

- Gyaran Ado da Na'urorin haɗi don OEM

- Gyaran Ado da Na'urorin haɗi don Motoci

- Kayayyakin Mabukaci (Kwayoyin Wayar Salula, Lantarki, Kayan Aiki)

- Iri-iri na kayan ado na laminate filastik

- Ƙirƙirar al'ada don biyan duk buƙatunku - farashi, dorewa da kamanni

- Ikon samar da samfura da sauri a cikin ƙananan ƙima don tabbatar da ra'ayi da amincewar shirin don amincewar abokin ciniki na ƙarshe

- Yawancin hular sinadarai masu juriya a cikin masana'antu suna samuwa don sassan da dole ne su kasance masu ɗorewa