CNC Machining Service

CNC Machining Akwai Tsari

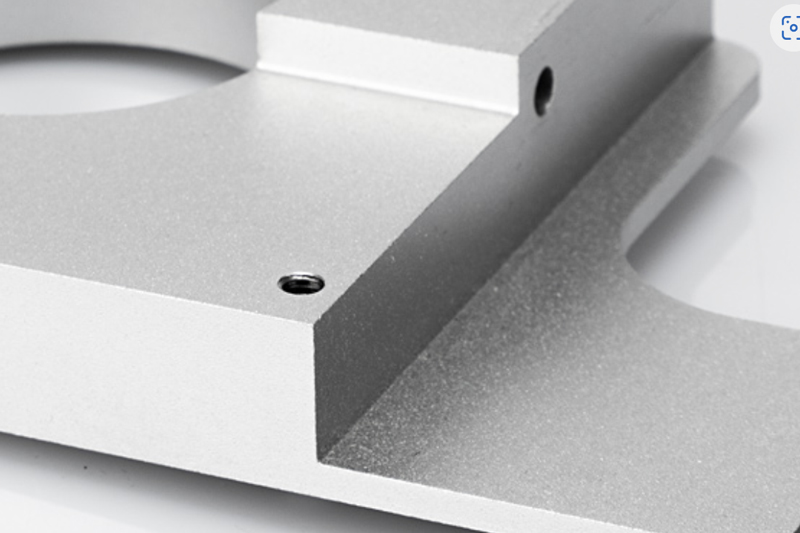

CNC Milling Service

Tare da sama da 50sets na 3, 4, da 5-axis CNC inji don samar da mafi girman juriya har zuwa ± 0.0008 ″ (0.02 mm) Daidaitaccen sassan CNC milling. Shagon injunan kan layi don sarrafa samfura da samarwa.

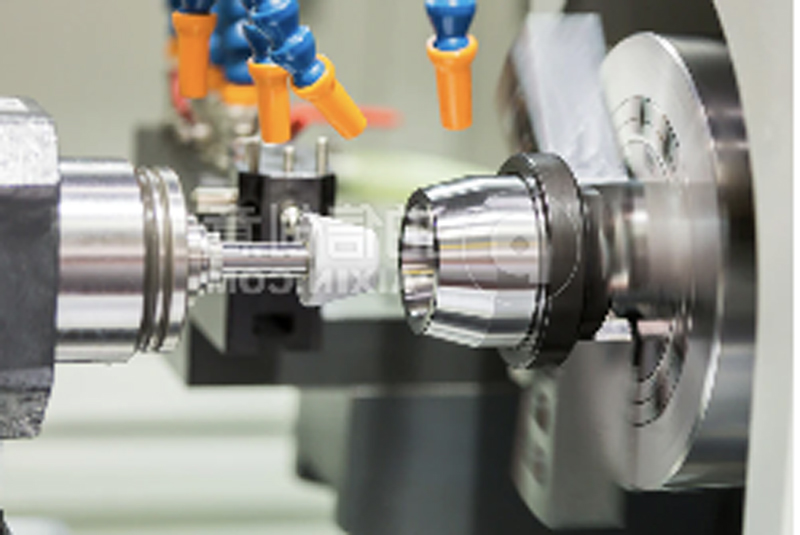

Sabis na Juyawar CNC

80+ CNC Lathes da CNC juya cibiyoyin, na iya ba da sabis na mashin daidaitaccen farashi tare da amsa mai sauri. 15+ shekaru ƙwararrun injiniyoyi don tallafawa tare da samfuran hadaddun.

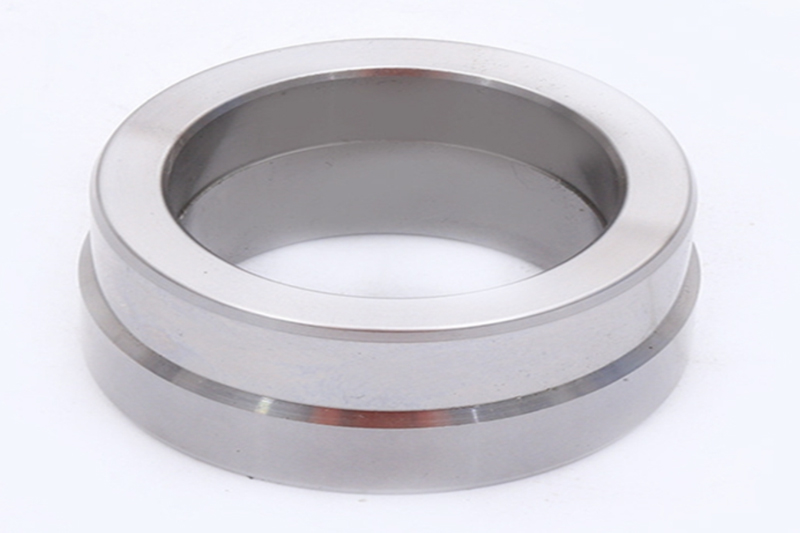

Injin Dillancin Lantarki (EDM)

Hanyar mashin ɗin da ba ta tuntuɓar mashin ɗin ba don ƙaƙƙarfan tsari. nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan kayan aikin lantarki (EDM) da muke bayarwa, Waya EDM da Sinker EDM. Hanyoyin da ake amfani da su suna da amfani don yankan aljihu mai zurfi da siffofi masu rikitarwa irin su gears da ramuka tare da maɓalli.

CNC Machining Applications

Kayan aikin gaggawa

CNC machining shine cikakken bayani don ƙirƙirar kayan aiki ko ƙira. CNC machining iya yanke wani babban iri-iri na cikakken m, m kayan kamar aluminum 5052 da bakin karfe.

Saurin Samfura

Samfuran da za a shirya cikin kwana 1. Muna da ƙwararrun mashinan 20+ don tallafawa samfurori masu sauri da inganci. Za a iya amfani da nau'ikan ƙarfe na ƙarfe da robobi masu araha don samfuran samfuri.

Ƙarshen Amfani da Samfura

M tolerances matsayin low as +/- 0.001”, certifiable abu zažužžukan da daban-daban surface jiyya matakai sa CNC machining wani kyakkyawan fasaha ga karshen-amfani sassa. Dubu guda su zama a shirye a cikin kwanaki.

CNC Machining Materials Selection ---- Karfe

FCE zai taimake ku nemo mafi kyawun abu bisa ga buƙatun samfur da aikace-aikacen. Zaɓi tsakanin sauri da zaɓuɓɓuka masu tsada don nemo mafi kyawun abu.

CNC Machining Aluminum Alloys

Aluminum 6061

Aluminum 5052

Aluminum 2024

Aluminum 6063

Aluminum 7050

Aluminum 7075

Aluminum MIC-6

CNC Machining Copper Alloys

Copper 101

Copper C110

CNC Machining Bronze Alloys

Farashin C932

CNC Machining Brass Alloys

Copper 260

Copper 360

CNC Machining Bakin Karfe Alloys

Nitronic 60 (218 SS)

Bakin Karfe 15-5

Bakin Karfe 17-4

Bakin Karfe 18-8

Bakin Karfe 303

Bakin Karfe 316/316L

Bakin Karfe 416

Bakin Karfe 410

Bakin Karfe 420

Bakin Karfe 440C

· CNC Machining Karfe Alloys

Karfe 1018

Karfe 1215

Karfe 4130

Karfe 4140

Karfe 4140PH

Karfe 4340

Karfe A36

CNC Machining Titanium Alloys

Titanium (Girki na 2)

Titanium (Mai daraja 5)

CNC Machining Zinc Alloys

Zinc Alloy

CNC Machining Materials Selection ---- Filastik

FCE zai taimake ku nemo mafi kyawun abu bisa ga buƙatun samfur da aikace-aikacen. Zaɓi tsakanin sauri da zaɓuɓɓuka masu tsada don nemo mafi kyawun abu.

· ABS

Ana iya yin amfani da ABS cikin sauƙi ta hanyar daidaitattun dabarun injina, kamar juyawa, niƙa, hakowa da sawing.

· Acrylic

Filastik mai haske kamar gilashi, ana amfani da shi don amfani da waje. Kyakkyawan lalacewa da tsagewar kaddarorin.

Delrin (Acetal)

Delrin yana da juriya mai kyau na danshi, juriya mai ƙarfi, da ƙarancin juriya.

Garolite G10

G10 mai ƙarfi ne, mai iya yin injina kuma yana da wutar lantarki. Anyi shi da resin epoxy mai hana wuta tare da ƙarfafa masana'anta na fiberglass.

· HDPE

Babban polyethylene mai girma shine danshi da filastik mai jurewa da sinadarai tare da ƙarfin tasiri mai kyau. Yawanci ana amfani dashi don aikace-aikacen waje, kwantena mara ruwa da hatimi.

· Nailan 6/6

Nylon 6/6 yana ƙara ƙarfin injin, tsauri, kwanciyar hankali mai kyau a ƙarƙashin yana ba da juriya na zafi da / ko sinadarai.

PC (Polycarbonate)

PC yana da mafi girman inji da kaddarorin tsari. An yi amfani da shi sosai a cikin motoci, sararin samaniya, da sauran aikace-aikacen da ke buƙatar dorewa da kwanciyar hankali.

· KYAUTA

Ana yawan amfani da PEEK azaman madadin abu mara nauyi don sassan ƙarfe. Yawanci ana amfani dashi a cikin matsanancin zafin jiki, aikace-aikacen damuwa. PEEK yana tsayayya da sinadarai, lalacewa, da danshi, yana ba da kyakkyawan ƙarfi mai ƙarfi,

· Polypropylene

Polypropylene sinadari ne ko juriya na lalata. Yana da kyawawan kaddarorin lantarki da ɗanɗano ko rashin sha. Yana ɗaukar nauyi masu sauƙi na dogon lokaci a cikin yanayin zafi dabam dabam.

PTFE (Teflon)

PTFE ya zarce mafi yawan robobi idan ya zo ga juriya da aiki a cikin matsanancin yanayin zafi. Yana tsayayya da mafi yawan kaushi kuma shine kyakkyawan insulator na lantarki.

· UHMW PE

Polyethylene mai nauyi mai girman gaske. UHMW PE ba ya sha danshi kuma yana ba da haɗin kai na musamman na lalacewa da juriya na lalata, babban juriya na sinadarai, ƙananan juzu'i, ƙarfin tasiri mai girma.

· PVC

Ana amfani da PVC da yawa a wuraren da aka fallasa ga ruwa ko kuma yana buƙatar rufin lantarki. Sannan kuma robobin roba ne mai juriya sosai

CNC Machining Surface ya ƙare

Standard (As-Milled)

Shi ne mafi saurin jujjuya aikin injina. Yana da ƙarancin ƙasa na 3.2 μm (126 μin). An cire duk masu kaifi, kuma an cire sassan. Ana iya ganin alamun kayan aiki.

Ƙwaƙwalwar ƙaya

An bar ɓangaren ɓangaren tare da santsi, matte bayyanar

Tumbled

Shi ne mafi saurin jujjuya aikin injina. Yana da ƙarancin ƙasa na 3.2 μm (126 μin). An cire duk masu kaifi, kuma an cire sassan. Ana iya ganin alamun kayan aiki.

Anodized

Za'a iya canza sassan sassa daban-daban cikin launuka daban-daban-Clear, baki, launin toka, ja, shuɗi, zinari.

Abin sha'awa

Za a iya zama anodized sassa cikin launuka daban-daban - baki, bayyananne, ja, da zinariya.

Gashi Powder

Za a iya zama anodized sassa cikin launuka daban-daban - baki, bayyananne, ja, da zinariya.

CNC Machining Design Guidelines

| Siffar | Bayani |

| Ciki kusurwa fillets | Zane fillet na kusurwa na ciki don zama 0.020” - 0.050” fiye da daidaitaccen girman rawar soja don radii. Bi diamita rawar soja zuwa zurfin rabo na 1:6 (1:4 shawarar) azaman jagora don radiyoyin kusurwa na ciki. |

| Fillet ɗin bene | Zane fillet ɗin bene ƙasa da fillet ɗin kusurwa don ba da damar kayan aiki iri ɗaya don share kayan daga ciki. |

| Yankewa | Koyaushe ƙira ƙananan yanke zuwa daidaitattun masu girma dabam kuma nesa da sasanninta don samun damar yin amfani da kayan aikin yankan. |

| Zurfin rami mai zare/Tafi | Samar da share kayan aiki kaɗan fiye da zurfin ramin da aka taɓa don tabbatar da cikakken zaren. |

| Abun rikitarwa | Rike adadin ƙananan raguwa zuwa ƙananan don rage farashin injin CNC; kawai ƙira a cikin abubuwan da ake buƙata don daidaita aiki tare da ado. |

Haƙuri na Machining CNC

| Siffar | Bayani |

| Matsakaicin Girman Sashe | Niƙa sassa har zuwa 80" x 48" x 24" (2,032 x 1,219 x 610 mm). |

| Daidaitaccen Lokacin Jagoranci | 3 kwanakin aiki |

| Gabaɗaya Haƙuri | Haƙuri akan karafa za a gudanar da su zuwa +/- 0.005" (+/- 0.127 mm) daidai da ISO 2768 sai dai in ba haka ba. |

| Madaidaicin Haƙuri | FCE na iya ƙirƙira da kuma bincika ƙaƙƙarfan haƙura bisa ƙayyadaddun zanenku gami da kiran GD&T. |

| Girman Siffa mafi ƙarancin | 0.020" (0.50 mm) Wannan na iya bambanta dangane da juzu'i da kayan da aka zaɓa. |

| Zare da Ramukan Tatsi | FCE na iya ɗaukar kowane daidaitaccen girman zaren. Hakanan zamu iya injin zaren al'ada; waɗannan za su buƙaci bita na ƙididdiga na hannu. |

| Yanayin Edge | An karye masu kaifi kuma an cire su ta tsohuwa |

| Ƙarshen Sama | Ƙimar ƙayyadaddun ƙayyadaddun kayan aiki ne: 125 Ra ko mafi kyau. Za a iya ƙayyade ƙarin zaɓuɓɓukan ƙarewa lokacin samun ƙima. |

Alkawarin ingancinmu