A cikin Lakabi na Mold

CNC Machining Akwai Tsari

Kwarewar Injiniya da Jagora

Teamungiyar injiniya za ta taimaka muku akan haɓaka ƙirar ɓangaren gyare-gyare, duba GD&T, zaɓin kayan. 100% tabbatar da samfurin tare da yuwuwar samarwa, inganci, ganowa

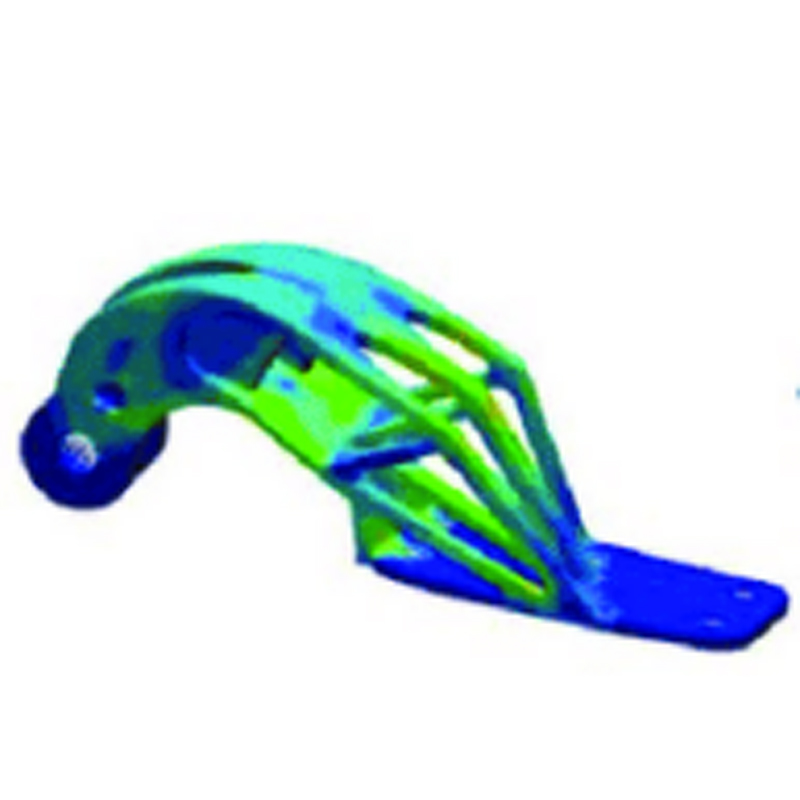

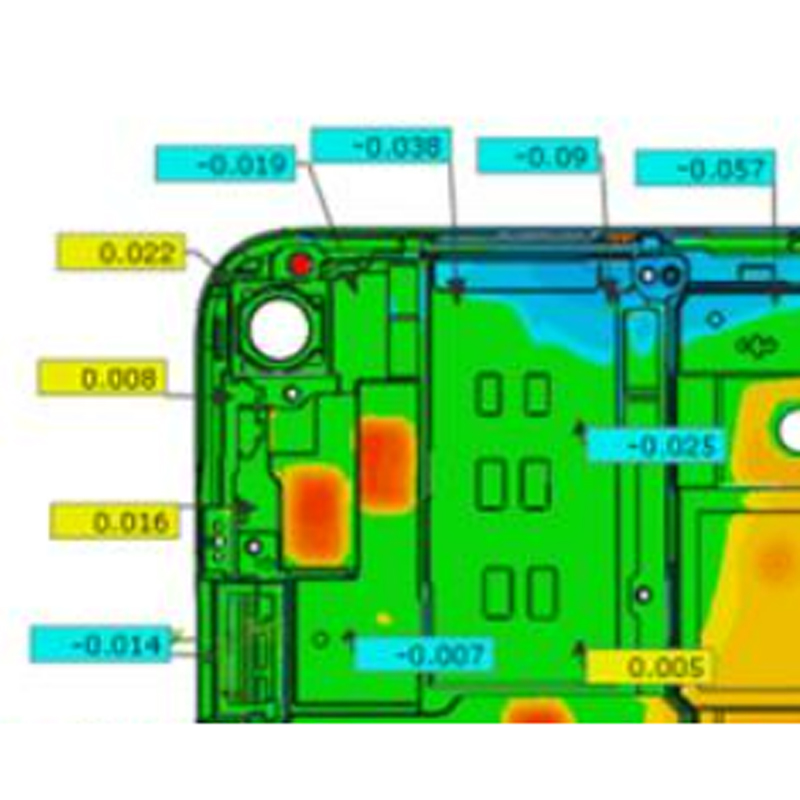

Simulation kafin Yanke Karfe

Ga kowane tsinkaya, za mu yi amfani da mold-flow, Creo, Mastercam don yin kwatankwacin tsarin gyare-gyaren allura, aikin injin, tsarin zane don hango hasashen batun kafin yin samfuran jiki.

An Karɓar Ƙirar Samfura

Muna da manyan wuraren masana'anta a cikin gyare-gyaren allura, injinan CNC da ƙirar ƙarfe. Wanne damar hadaddun, babban madaidaicin ƙira samfurin

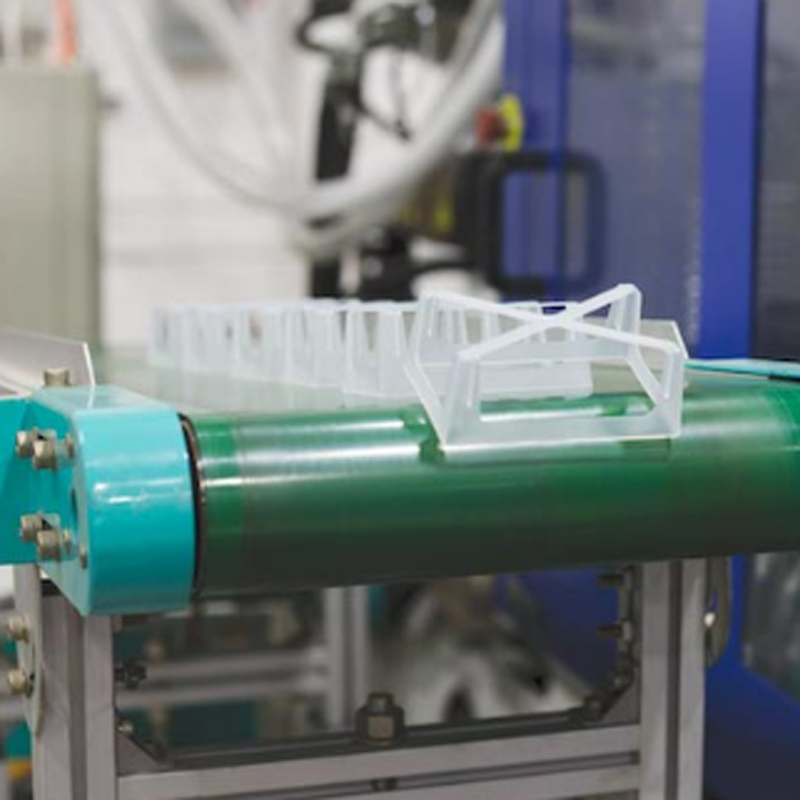

A cikin tsarin gida

Yin gyare-gyaren allura, gyare-gyaren allura da kuma tsari na biyu na bugu na pad, zafi stamping, zafi stamping, taro duk suna cikin gida, don haka za ku sami ƙarancin farashi da ingantaccen lokacin jagorar ci gaba.

A cikin Lakabi na Mold

A cikin Mold Labeling (IML) wani tsari ne na gyare-gyaren allura wanda ake yin kayan ado na ɓangaren filastik, ta amfani da lakabin, yayin aikin allurar filastik. A taƙaice, ana shigar da lakabin da aka riga aka buga ta hanyar sarrafa kansa a cikin rami na ƙirar allura kuma ana yin allurar filastik akan alamar. Wannan yana samar da wani ɓangaren filastik ƙawata / "lakabi" wanda aka haɗa alamar har abada zuwa ɓangaren kanta.

Fa'idodin dabarun yin lakabin Rosti in-mould sun haɗa da:

• Har zuwa 45% curvature na foil (zurfin zuwa faɗi)

• Dry da sauran ƙarfi free tsari

• Ƙirar ƙira mara iyaka

• Canjin ƙira mai sauri

• Hotuna masu girma

• Ƙananan farashi, musamman don ayyuka masu girma

Cimma tasirin da ba zai yuwu ba tare da wasu fasahohi

• Mai ƙarfi kuma mai ƙarfi don ajiyar tsabta na samfuran daskararru da firji

• Ƙare mai jurewa lalacewa

• Sanin muhalli

Amfanin IML

Wasu fa'idodin fasaha na IML sun haɗa da:

• Cikakken kayan ado na sashin da aka ƙera

• Dorewa na zane-zane: Ana kiyaye tawada ta fim a cikin gine-gine na biyu

• Ayyukan sakandare da ke da alaƙa da kayan ado bayan gyare-gyare an kawar da su

• Kawar da buƙatun wuraren lakabin da aka soke

• Fina-finai da yawa da gine-gine da ke akwai don saduwa da bukatun abokin ciniki

• Sauƙi don samar da aikace-aikacen launuka masu yawa

• Gabaɗaya ƙananan ƙima

• Mai ɗorewa kuma mai hanawa

• Madaidaicin launi mafi girma

• Babu wurin da datti zai iya tarawa

• Akwai launuka marasa iyaka

A cikin Aikace-aikacen Lakabi na Mold

Ya dace sosai ga tunanin ku don yanke shawarar irin ayyukan da za su iya amfani da lakabin a cikin-mold, amma ga wasu ayyuka masu gudana da masu zuwa;

- busassun matattarar tumbler, don sarrafa kansa a cikin tsarin ciyarwa

- alamar sirinji da vials

- codeing da alamar abubuwan da aka gyara don masana'antar kera motoci

- keɓance samfuran don masana'antar magunguna da sauransu

- gano samfuran tare da RFID

- yin ado da kayan da ba na al'ada ba kamar su yadi

Jerin za a iya yin tsayi da yawa kuma nan gaba za su nuna sabbin waɗanda ba a ji ba tukuna aikace-aikacen da za su sa samar da arha da sauri, haɓaka inganci da haɓaka aminci, ganowa da rarrabawa.

A cikin Material Labeling Mold

Adhesion tsakanin tsare-tsare daban-daban da kayan da aka wuce gona da iri

| Abubuwan da aka yi yawa | |||||||||||||||||

| ABS | ASA | EVA | PA6 | PA66 | PBT | PC | PEHD | PELD | PET | PMMA | POM | PP | PS-HI | SAN | TPU | ||

| Kayan da aka rufe | ABS | ++ | + | + | + | + | - | - | + | + | - | - | ∗ | + | + | ||

| ASA | + | ++ | + | + | + | - | - | + | + | - | - | - | + | + | |||

| EVA | + | + | ++ | + | + | + | + | + | |||||||||

| PA6 | ++ | + | ∗ | ∗ | ∗ | ∗ | - | ∗ | - | + | + | ||||||

| PA66 | + | ++ | ∗ | ∗ | ∗ | ∗ | - | - | - | + | + | ||||||

| PBT | + | + | ∗ | ∗ | ++ | + | - | - | + | - | - | - | - | + | + | ||

| PC | + | + | ∗ | ∗ | + | ++ | - | - | + | + | - | - | - | + | + | ||

| PEHD | - | - | + | ∗ | ∗ | - | - | ++ | + | - | ∗ | ∗ | - | - | - | - | |

| PELD | - | - | + | ∗ | ∗ | - | - | + | ++ | - | ∗ | ∗ | + | - | - | - | |

| PET | + | + | + | + | - | - | + | - | - | - | + | ||||||

| PMMA | + | + | - | - | ∗ | ∗ | - | ++ | ∗ | - | + | ||||||

| POM | - | - | - | - | - | - | ∗ | ∗ | - | ++ | - | - | - | ||||

| PP | - | - | + | ∗ | - | - | - | - | + | ∗ | - | ++ | - | - | - | ||

| PS-HI | ∗ | - | + | - | - | - | - | - | - | - | - | - | - | ++ | - | - | |

| SAN | + | + | + | + | + | + | + | - | - | + | - | - | - | ++ | + | ||

| TPU | + | + | + | + | + | + | - | - | + | - | - | + | + | ||||

++ Kyakkyawan mannewa, + Kyakkyawan mannewa, ∗ Rashin mannewa, - Babu mannewa.

EVA, Ethylene vinyl acetate; PA6, Polyamide 6; PA66, Polyamide 66; PBT, Polybutylene terephthalate; PEHD, babban yawa na polyethylene; PELD, ƙananan ƙarancin polyethylene; POM, Polyoxymethylene; PS-HI, Babban Tasirin Polystyrene; SAN, Styrene Acrylonitrile; TPU, Thermoplastic polyurethane.

Ƙarfin dangi na IML vs. IMD alamar mafita

Haɗa tsarin kayan ado tare da tsarin gyare-gyare yana ƙara ƙarfin aiki, rage farashin masana'anta kuma yana haifar da sassaucin ƙira.

Dorewa

Zane-zane ba zai yiwu a cire ba tare da lalata ɓangaren filastik ba kuma zai kasance mai ƙarfi ga rayuwar ɓangaren. Akwai zaɓuɓɓuka don haɓakar ɗorewa a cikin yanayi mai tsauri da juriya na sinadarai.

Tasirin farashi

IML yana kawar da lakabin gyare-gyare bayan gyare-gyare, sarrafawa da ajiya. Yana rage kayan WIP da ƙarin lokacin da ake buƙata don kayan ado bayan samarwa, akan- ko a waje.

Zane sassauci

IML yana samuwa a cikin nau'i-nau'i na launuka, tasiri, laushi da zaɓuɓɓuka masu hoto kuma yana iya yin kwafi ko da mafi ƙalubalanci kama kamar bakin karfe, hatsin itace da fiber carbon. Lokacin da ake buƙatar takaddun shaida na UL, ana ƙididdige samfuran alamar in-mold daidai da daidaitattun ƙa'idodin aminci waɗanda aka yi amfani da su don kimanta alamun matsi.