SLA

SLA Hoʻolālā alakaʻi

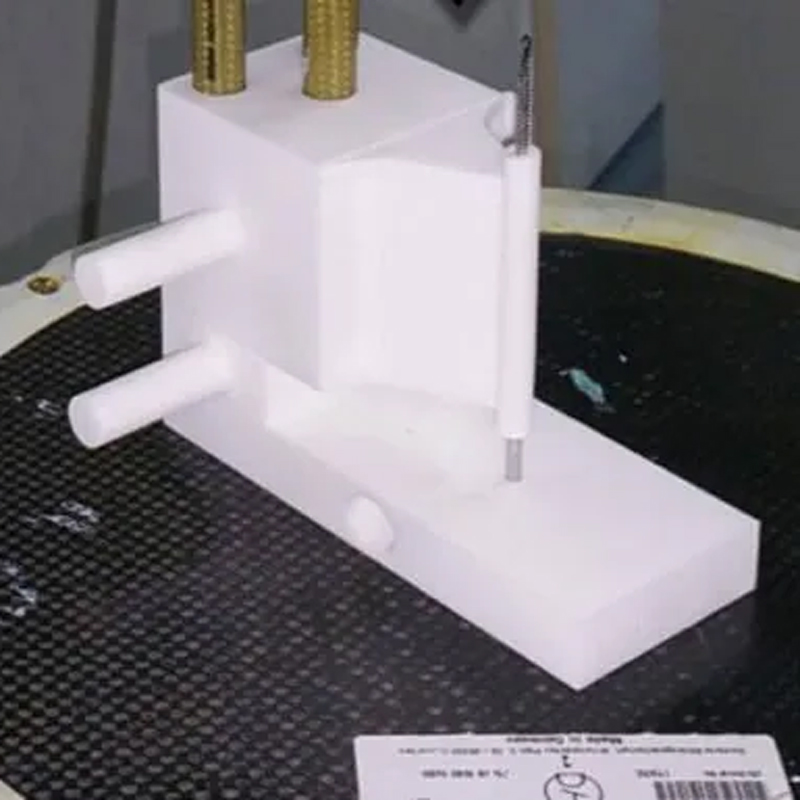

Hoʻoholo paʻi

ʻO ka mānoanoa papa maʻamau: 100 µm Pono: ±0.2% (me ka palena haʻahaʻa o ±0.2 mm)

Ka palena nui 144 x 144 x 174 mm Mānoanoa liʻiliʻi ʻO ka mānoanoa liʻiliʻi o ka pā 0.8mm – Me ka ratio 1:6

Hoʻopili a hoʻopaʻa inoa

Nā kikoʻī liʻiliʻi kiʻekiʻe a me ka laula i hoʻopaʻa ʻia: 0.5 mm

Kauʻia: 0.5 mm

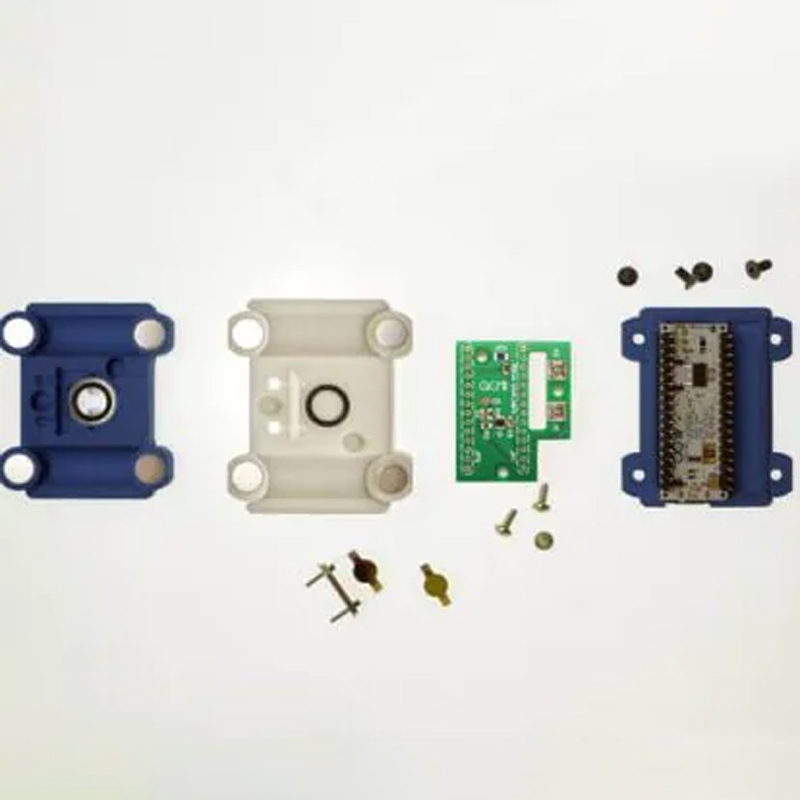

Hoʻopili ʻia a hui pū ʻia

Nā ʻāpana i hoʻopili ʻia? ʻAʻole paipai ʻia nā ʻāpana Interlocking? ʻAʻole ʻōlelo ʻia

ʻĀpana hui ʻāpana

Ahahui? ʻAʻole

ʻIke ʻenekinia a me ke alakaʻi

E kōkua ka hui ʻenehana iā ʻoe i ka hoʻolālā ʻana i ka hoʻolālā ʻāpana, GD&T nānā, koho mea. 100% hōʻoia i ka huahana me ka hana kiʻekiʻe hiki ke kūpono, maikaʻi, traceability

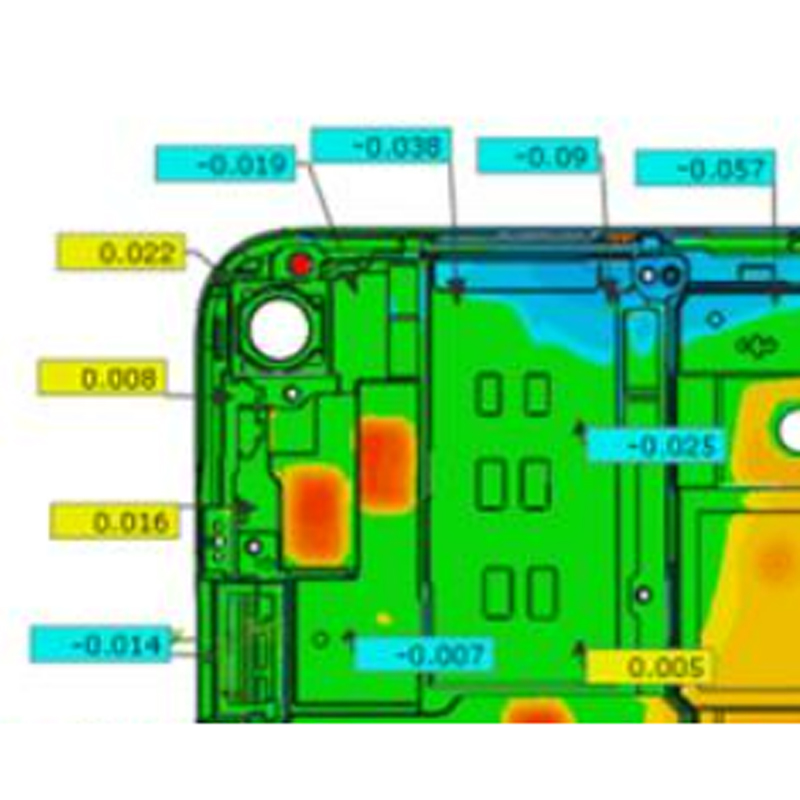

Hoʻohālikelike ma mua o ka ʻoki ʻana i ke kila

No kēlā me kēia projection, e hoʻohana mākou i ka mold-flow, Creo, Mastercam e hoʻohālikelike i ke kaʻina hana hoʻoheheʻe ʻia, ka hana machining, ke kaʻina hana kiʻi e wānana i ka pilikia ma mua o ka hana ʻana i nā laʻana kino.

Hoʻolālā Huahana Paʻakikī

Loaʻa iā mākou nā keʻena hana ʻoihana kiʻekiʻe i ka hoʻoheheʻe ʻana, CNC machining a me ka hana ʻana i ka metala. ʻO ia ka mea e hiki ai i ka hoʻolālā huahana koi paʻakikī

Kaʻina hale

Injection mold making, Injection molding a me ke kaʻina hana ʻelua o ka paʻi pad, heat stamping, hot stamping, hui ʻia i loko o ka hale, no laila e loaʻa iā ʻoe ke kumu kūʻai haʻahaʻa a me ka manawa alakaʻi hoʻomohala hilinaʻi.

Nā Pōmaikaʻi o ka Paʻi SLA

kūlana kiʻekiʻe o nā kikoʻī

Inā makemake ʻoe i ka pololei, ʻo SLA ke kaʻina hana hoʻohui e pono ai ʻoe e hana i nā prototypes kikoʻī loa

Nā noi like ʻole

Mai ka automotive i nā huahana mea kūʻai aku, nui nā hui e hoʻohana ana i ka Steeolithography no ka prototyping wikiwiki

Kūʻokoʻa hoʻolālā

Hiki iā ʻoe ke hana i nā geometries paʻakikī

Noi SLA

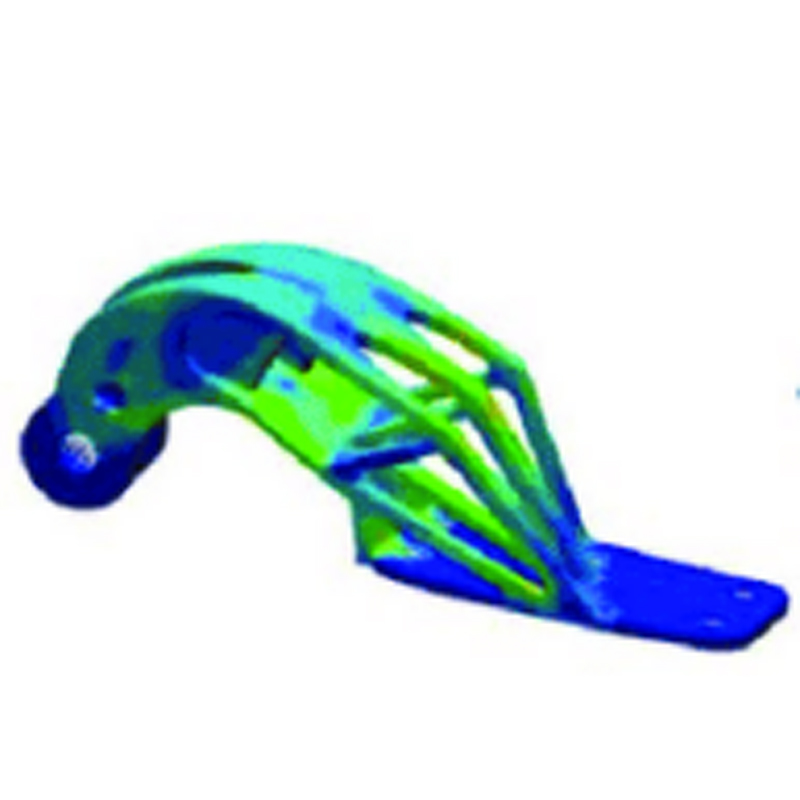

Kaʻa kaʻa

Ka mālama ola kino a me ka Lapaʻau

Mechanics

ʻenehana kiʻekiʻe

Na Mea Hana Hana

Electronics

SLA vs SLS vs FDM

| Inoa Waiwai | ʻAiʻoniʻoni | Hoʻopaʻa ʻia ʻo Laser Sintering | Hoʻohālike Hoʻohuihui |

| Pōʻokoʻa | SLA | SLS | FDM |

| ʻAno mea | wai (Phopolymer) | Pauda (Polymer) | Paʻa (Filaments) |

| Nā mea waiwai | ʻO nā Thermoplastics (Elastomers) | Nā Thermoplastics e like me Nylon, Polyamide, a me Polystyrene; Elastomers; Huipuia | Nā Thermoplastics e like me ABS, Polycarbonate, a me Polyphenylsulfone; Nā Elastomers |

| Nui hapa nui (in.) | 59.00 x 29.50 x 19.70 | 22.00 x 22.00 x 30.00 | 36.00 x 24.00 x 36.00 |

| Min hiʻona nui (in.) | 0.004 | 0.005 | 0.005 |

| Mānoanoa papa liʻiliʻi (in.) | 0.0010 | 0.0040 | 0.0050 |

| Hoʻomanawanui (in.) | ±0.0050 | ±0.0100 | ±0.0050 |

| Hoʻopau ʻili | Maalahi | Awelika | ʻOʻohe |

| Ka māmā holo | Awelika | wikiwiki | lohi |

| Nā noi | ʻO ka hoʻāʻo ʻana i ke ʻano, ka hoʻāʻo ʻana, nā ʻano mea hana wikiwiki, Snap kūpono, nā ʻāpana kikoʻī loa, Nā hiʻohiʻona hōʻike, nā noi wela kiʻekiʻe | ʻO ka hoʻāʻo ʻana i ke ʻano, ka hoʻāʻo hana, nā ʻano mea hana wikiwiki, nā ʻāpana kikoʻī liʻiliʻi, Nā ʻāpana me nā paʻi paʻa a me nā ʻūlū ola, Nā noi wela kiʻekiʻe | ʻO ka hoʻāʻo ʻana i ke ʻano, ka hoʻāʻo hana, nā ʻano mea hana wikiwiki, nā ʻāpana kikoʻī liʻiliʻi, nā hiʻohiʻona hōʻike, nā noi maʻi a me nā meaʻai, nā noi wela kiʻekiʻe |

SLA Pōmaikaʻi

He wikiwiki ka Steeolithography

Pololei ka Steeolithography

Hana ʻia ka Steeolithography me nā mea like ʻole

Hoʻomau

Hiki ke Hui Nui

Hiki ke Texturing