Hoʻopaʻa Metala Pepa Maʻamau

Ikona

Kākoʻo ʻenekinia

No ka hōʻoia ʻana i ka holomua o ka huahana a me ka maikaʻi, e kaʻana like ka hui ʻenekinia i ko lākou ʻike, kōkua me ka hoʻolālā ʻāpana ʻāpana, nānā GD&T, a me ke koho ʻana i nā mea.

Hoʻouna wikiwiki

Hiki ke hōʻemi ʻia nā laʻana i hoʻokahi lā hoʻouna. ʻOi aku ma mua o 5000 mau ʻano waiwai maʻamau, ʻoi aku ma mua o 40 mau mīkini e kākoʻo i kāu mau koi wikiwiki.

E ʻae i ka hoʻolālā paʻakikī

ʻO ia ka mea e ʻae ai i nā koi hoʻolālā huahana paʻakikī, kiʻekiʻe, loaʻa iā mākou kahi hōʻailona papa mua o ka ʻoki ʻana i ka laser, ka kuʻi ʻana, ka wili a me nā mea hoʻāʻo.

I ka hale 2nd kaʻina

Loaʻa iā mākou ka pauka pauka i nā kala like ʻole a me nā luminances, pad / pale paʻi a me nā hōʻailona hōʻailona wela, riveting a me ka welding, a me ka hui pahu.

Kaʻina Metala Pepa

ʻO ka lawelawe hana pepa FCE, hiki ke hoʻopau i ke kuʻi, ʻōwili, kaha kiʻi, kiʻi hohonu a me nā kaʻina hana ʻē aʻe i hoʻokahi papa hana. Hiki iā ʻoe ke loaʻa nā huahana piha loa me ke kūlana kiʻekiʻe a me nā manawa alakaʻi pōkole loa.

Kulou ana

ʻO ka piʻo ʻana he hana metala kahi e hoʻopili ʻia ai ka ikaika i kahi ʻāpana metala ʻē aʻe, e piʻo ai i kahi Angle e hana i ke ʻano i makemake ʻia. ʻO nā hana kulou e hoʻololi i ke kumu a hiki ke hana i nā ʻano hana like ʻole e hana i kahi mea paʻakikī. Hiki ke liʻiliʻi loa ka ʻāpana piko, e like me ka bracket, e like me ka pūpū nui a i ʻole chassis

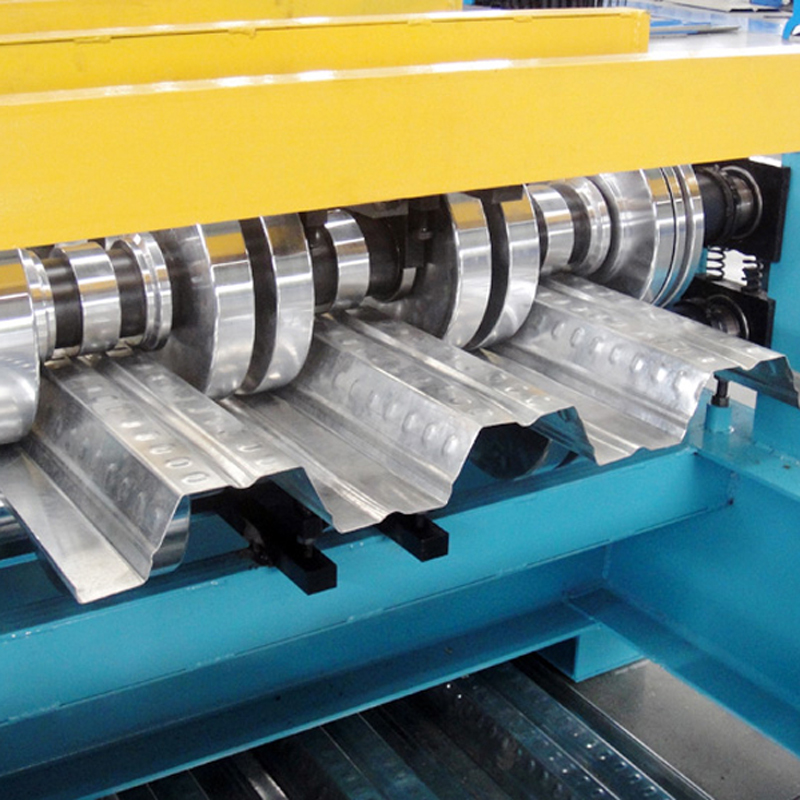

ʻO ka ʻōwili ʻana

ʻO ka hoʻowili ʻana, he kaʻina hana metala kahi e hoʻopololei ʻia ai ka lau metala ma o ke ʻano o nā hana pelu. Hana ʻia ke kaʻina hana ma ka laina ʻōwili. Loaʻa i kēlā me kēia kikowaena kahi ʻōwili, i kapa ʻia he roller die, hoʻonoho ʻia ma nā ʻaoʻao ʻelua o ka pepa. ʻO ke ʻano a me ka nui o ka huila make ʻokoʻa paha i kēlā keʻena, a i ʻole e hoʻohana ʻia kekahi mau mea like ʻole ma nā kūlana like ʻole. Hiki ke make ka ʻōwili ma luna a ma lalo o ka pepa, ma nā ʻaoʻao, ma kahi kihi, a pēlā aku.

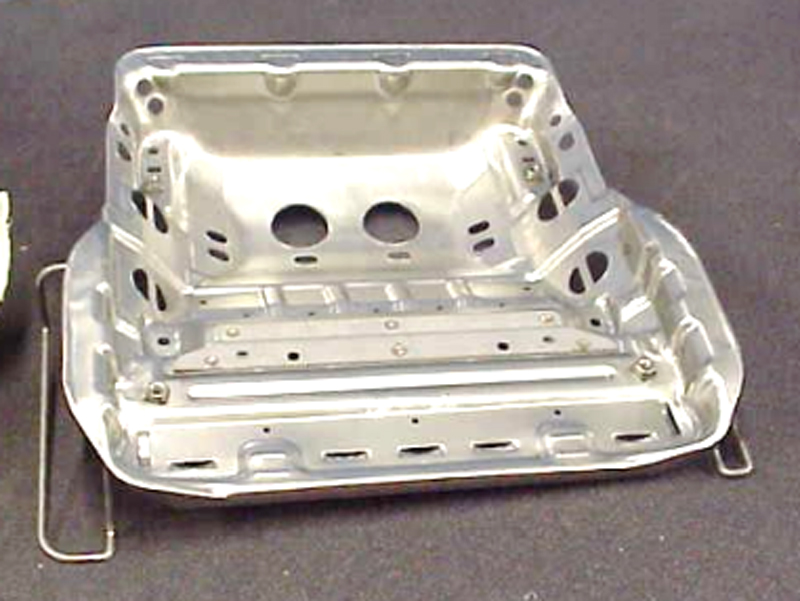

Kiʻi hohonu

ʻO ka hana ʻana i ka ʻōwili he ʻenehana hoʻoheheʻe ʻia e hana liʻiliʻi i ka metala lau ma o ke ʻano o ka ʻenehana kaʻina hana kulou. Hana ʻia ke kaʻina hana ma kahi laina hana ʻōwili. Loaʻa i kēlā me kēia keena kahi ʻōwili, i kapa ʻia he roller die, ma kēlā me kēia ʻaoʻao o ka pepa. He ʻokoʻa ke ʻano a me ka nui o nā ʻōwili ʻōwili, a i ʻole hiki ke hoʻohana ʻia nā ʻāpana ʻōwili like ʻole ma nā wahi like ʻole. Hiki ke hoʻohana ʻia ka make roller ma luna a ma lalo o ka pepa, ma ka ʻaoʻao, ma kahi Angle, etc.

Ke kaha kiʻi no nā ʻano paʻakikī

Loaʻa iā FCE ka ʻike i ka hana ʻana i nā ʻāpana metala o nā ʻaoʻao paʻakikī. Ma waho aʻe o ke kaha kiʻi hohonu, ua loaʻa nā ʻāpana maikaʻi maikaʻi i ka hana hoʻāʻo mua ma o ka nānā ʻana i ka element finite.

Ka hao ana

Ke hao ʻia nei ka lau metala no ka loaʻa ʻana o ka mānoanoa. Me kēia kaʻina hana, hiki iā ʻoe ke dilute ma nā paia ʻaoʻao o ka huahana. ʻO ka mānoanoa o lalo. ʻO nā noi maʻamau he kini, kīʻaha, etc.

Loaʻa nā mea hana no ka hana ʻana i ka metala

Ua hoʻomākaukau ʻo FCE i 1000+ mau mea pepa maʻamau i loko o ke kumukūʻai no ka huli wikiwiki ʻana, E kōkua kā mākou ʻenekinia mīkini iā ʻoe ma ke koho ʻana i nā mea waiwai, ka nānā ʻana i nā mīkini, nā loiloi kūpono.

| Aluminum | keleawe | keleawe | kila |

| Aluminum 5052 | Ke keleawe 101 | keleawe 220 | ʻO ke kila kila 301 |

| Aluminum 6061 | Ke keleawe 260 (Ke keleawe) | keleawe 510 | ʻAi ʻole 304 |

| Ke keleawe C110 | He kila kila 316/316L | ||

| kila, kalapona haahaa |

Hoʻopau i ka ʻili

Hāʻawi ʻo FCE i nā kaʻina hana lapaʻau piha. Hiki ke hoʻopilikino ʻia ka electroplating, ka pauka, anodizing e like me ke kala, ke ʻano a me ka ʻōlinolino. Hiki ke ʻōlelo ʻia ka hoʻopau kūpono e like me nā koi hana.

Palaki

Pahū ʻana

ʻO ka hoʻopololei

Anodizing

ʻO ka pauka

Hoololi Wela

Pāpalapala

Pa'i & Hoailona Laser

ʻO kā mākou ʻōlelo hoʻohiki maikaʻi

Nā nīnau nīnau maʻamau

He aha ka Sheet Metal Fabrication?

ʻO ka hoʻoili metala he kaʻina hana subtractive kahi e ʻoki ʻia ai nā ʻāpana a i ʻole i hana ʻia mai ka ʻāpana metala. Hoʻohana pinepine ʻia nā ʻāpana metala no ka pololei kiʻekiʻe a me nā koi paʻa, me nā noi maʻamau he chassis, enclosures a me nā brackets.

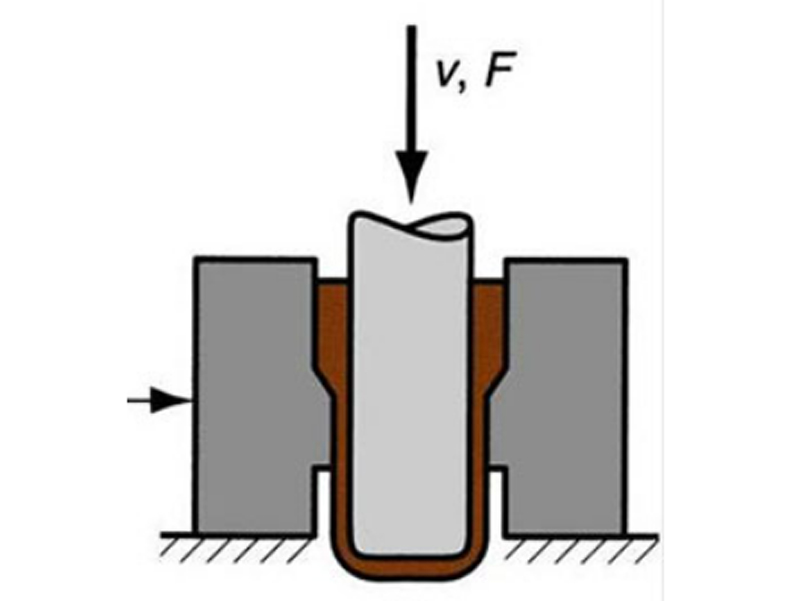

He aha ka Sheet Metal Forming?

ʻO ka hana ʻana i ka metala he hana ia e hoʻohana ʻia ai ka ikaika i kahi metala e hoʻololi i kona ʻano ma mua o ka wehe ʻana i kekahi mea. ʻO ka ikaika i hoʻohana ʻia e hana i ka metala ma mua o kona ikaika e hoʻohua ai, e hoʻoneʻe i ka mea i ka plastic deformation, akā ʻaʻole e haki. Ma hope o ka hoʻokuʻu ʻia ʻana o ka ikaika, e hoʻihoʻi iki ka pā, akā mālama mau i ke ʻano ke kaomi ʻana.

He aha ke kuʻi ʻana metala?

I mea e hoʻomaikaʻi ai i ka maikaʻi o ka hana ʻana i nā lau metala, hoʻohana ʻia nā mea hoʻoheheʻe metala e hoʻololi i nā metala palahalaha i nā ʻano kikoʻī. He kaʻina hana paʻakikī kēia e hiki ai ke hoʻokomo i nā ʻenehana hana metala he nui - hoʻopololei, kuʻi, kuʻi a me ke kuʻi.

He aha ka manawa uku?

Nā mea kūʻai hou, 30% i lalo. E kaulike i ke koena ma mua o ka lawe ʻana i ka huahana. ʻAe mākou i kahi manawa hoʻoponopono ʻekolu mahina no nā kauoha maʻamau