Ma ka Lepili Mold

Hiki ke Kaʻina Hana Hana CNC

ʻIke ʻenekinia a me ke alakaʻi

E kōkua ka hui ʻenehana iā ʻoe i ka hoʻolālā ʻana i ka hoʻolālā ʻāpana, GD&T nānā, koho mea. 100% hōʻoia i ka huahana me ka hana kiʻekiʻe hiki ke kūpono, maikaʻi, traceability

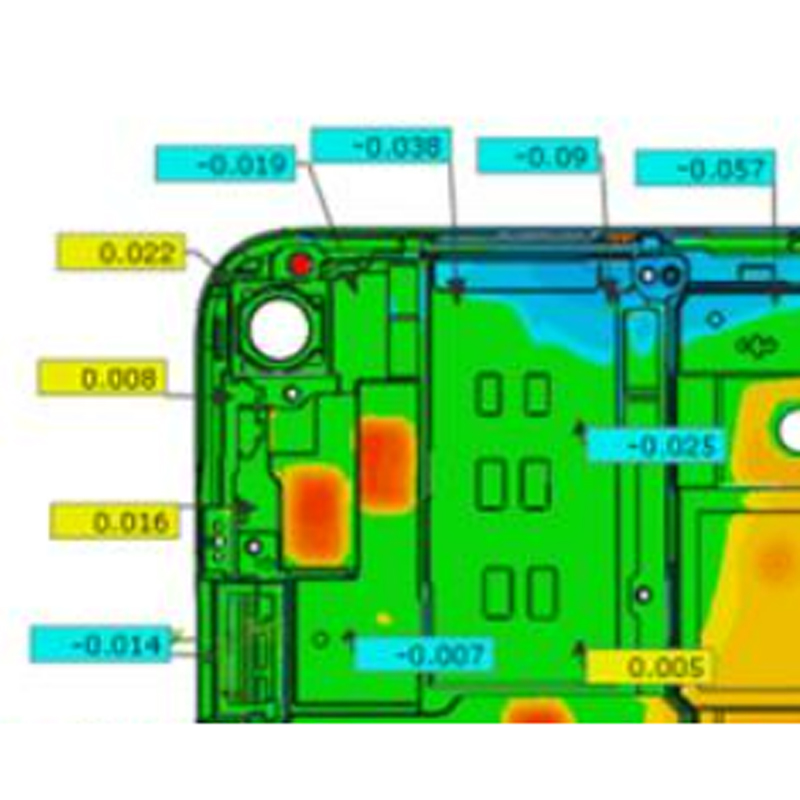

Hoʻohālikelike ma mua o ka ʻoki ʻana i ke kila

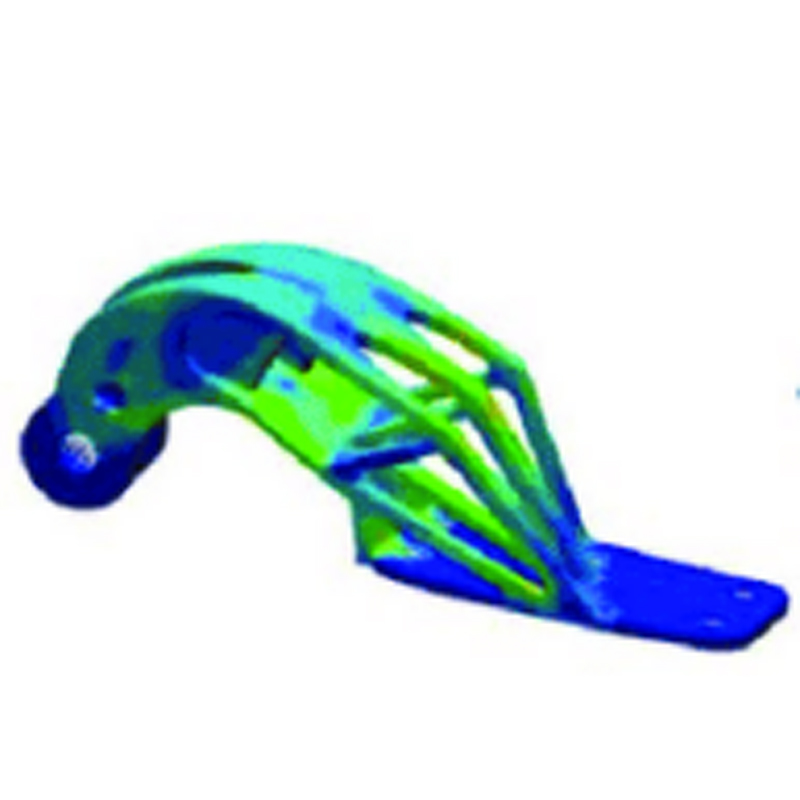

No kēlā me kēia projection, e hoʻohana mākou i ka mold-flow, Creo, Mastercam e hoʻohālikelike i ke kaʻina hana hoʻoheheʻe ʻia, ka hana machining, ke kaʻina hana kiʻi e wānana i ka pilikia ma mua o ka hana ʻana i nā laʻana kino.

Ua ʻae ʻia ka hoʻolālā huahana paʻakikī

Loaʻa iā mākou nā keʻena hana ʻoihana kiʻekiʻe i ka hoʻoheheʻe ʻana, CNC machining a me ka hana ʻana i ka metala. ʻO ia ka mea e hiki ai i ka hoʻolālā huahana koi paʻakikī

Kaʻina hale

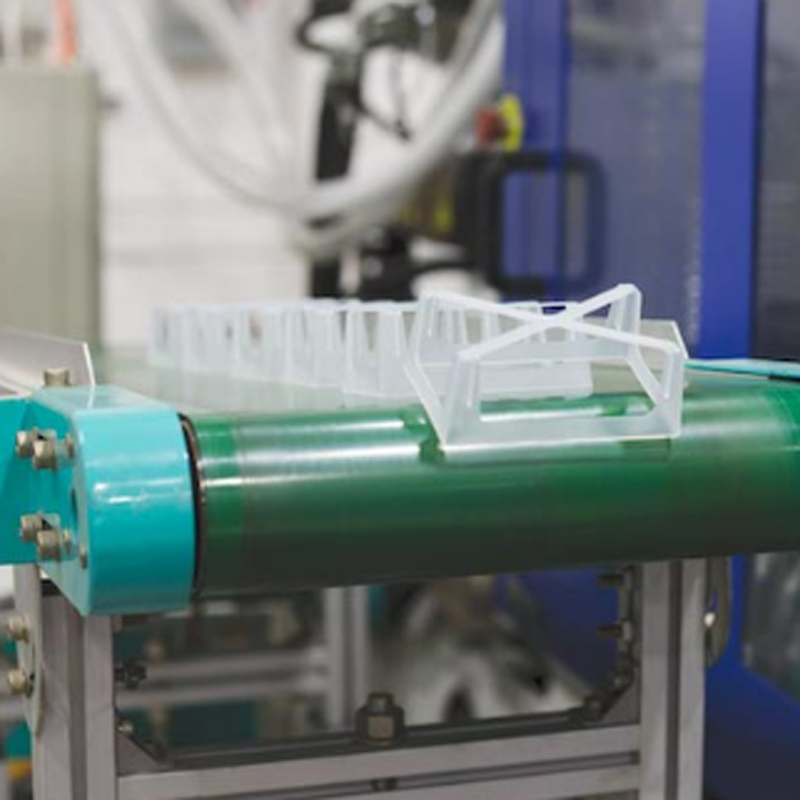

Injection mold making, Injection molding a me ke kaʻina hana ʻelua o ka paʻi pad, heat stamping, hot stamping, hui ʻia i loko o ka hale, no laila e loaʻa iā ʻoe ke kumu kūʻai haʻahaʻa a me ka manawa alakaʻi hoʻomohala hilinaʻi.

Ma ka Lepili Mold

ʻO ka Mold Labeling (IML) kahi kaʻina hana hoʻoheheʻe ʻia kahi e hana ʻia ai ka hoʻonaninani o ka ʻāpana plastic, me ka hoʻohana ʻana i kahi lepili, i ka wā o ke kaʻina hana ʻilika. Hoʻopuka maʻalahi, hoʻokomo ʻia kahi lepili i paʻi mua ʻia ma o ka automation i loko o ka lua o kahi mold injection a hoʻokomo ʻia ka plastic ma luna o ka lepili. Hoʻopuka kēia i kahi ʻāpana plastik i kāhiko ʻia / "labeled" kahi i hoʻopili mau ʻia ai ka lepili i ka ʻāpana ponoʻī

ʻO nā mea maikaʻi o Rosti in-mould labeling techniques:

• A hiki i ka 45% ka curvature foil (hohonu a laula)

• Kaʻina hana maloʻo a me ka solvent

• hiki ke hoʻolālā palena ʻole

• Hoʻololi hoʻolālā wikiwiki

• Nā kiʻi hoʻonā kiʻekiʻe

• Ke kumu kūʻai haʻahaʻa, ʻoi aku ka nui o nā papahana kiʻekiʻe

• Loaʻa i nā hopena hiki ʻole me nā ʻenehana ʻē aʻe

• Paʻa a paʻa no ka mālama maʻemaʻe o nā huahana hau a me ka pahu hau

• Hoʻopau pale-pōʻino

• Manao kaiapuni

Nā pono o ka IML

ʻO kekahi o nā pono ʻenehana o IML penei:

• Hoʻopiha piha i ka ʻāpana i hoʻoheheʻe ʻia

• Ka lōʻihi o nā kiʻi: Mālama ʻia nā ʻīnika e ke kiʻiʻoniʻoni ma nā kūkulu ʻili lua

• Hoʻopau ʻia nā hana ʻelua e pili ana i ka hoʻonaninani post-moulding

• Hoʻopau i ka pono no nā wahi hōʻailona hoʻomaha

• Nui nā kiʻiʻoniʻoni a me nā kūkulu hale e hoʻokō i nā koi o ka mea kūʻai aku

• ʻOi aku ka maʻalahi o ka hoʻopuka ʻana i nā noi lehulehu

• E hoemi mau ana i na uku oki

• ʻoi aku ka lōʻihi a me ka hōʻole ʻole

• Ke kaulike kala kiʻekiʻe

• ʻAʻohe wahi e ʻohi ai ka lepo

• Loaʻa nā kala palena ʻole

I loko o ka mold Labeling Application

Aia i kou manaʻo ponoʻī e hoʻoholo i nā papahana e hiki ke hoʻohana i ka lepili i loko, akā eia kekahi mau papahana e hoʻomau nei a hiki mai ana;

- nā kānana tumbler maloʻo, e hoʻomaʻamaʻa i ka hana hānai

- ka hōʻailona ʻana i nā syringes a me nā hue

- coding a me ka māka ʻana i nā ʻāpana no ka ʻoihana kaʻa

- pilikino o nā huahana no ka ʻoihana lāʻau lapaʻau etc

- hiki ke huli i nā huahana me RFID

- ka hoʻonani ʻana me nā mea maʻamau ʻole e like me nā textiles

Hiki ke hoʻolōʻihi ʻia ka papa inoa a e hōʻike ʻia i ka wā e hiki mai ana i nā mea hou i lohe ʻole ʻia e pili ana i nā noi e hana ʻoi aku ka maʻalahi a me ka wikiwiki, hoʻonui i ka maikaʻi a hoʻomaikaʻi i ka palekana, traceability a me ka hāʻawi ʻana.

Ma Mold Labeling Material

Hoʻopili ma waena o nā ʻāpana like ʻole a me nā mea overmoulding

| Mea hoʻoheheʻe ʻia | |||||||||||||||||

| ABS | ASA | EVA | PA6 | PA66 | PBT | PC | PEHD | PELD | PET | PMMA | POM | PP | PS-HI | SAN | TPU | ||

| Mea pepa pepa | ABS | ++ | + | + | + | + | − | − | + | + | − | − | ∗ | + | + | ||

| ASA | + | ++ | + | + | + | − | − | + | + | − | − | − | + | + | |||

| EVA | + | + | ++ | + | + | + | + | + | |||||||||

| PA6 | ++ | + | ∗ | ∗ | ∗ | ∗ | − | ∗ | − | + | + | ||||||

| PA66 | + | ++ | ∗ | ∗ | ∗ | ∗ | − | − | − | + | + | ||||||

| PBT | + | + | ∗ | ∗ | ++ | + | − | − | + | − | − | − | − | + | + | ||

| PC | + | + | ∗ | ∗ | + | ++ | − | − | + | + | − | − | − | + | + | ||

| PEHD | − | − | + | ∗ | ∗ | − | − | ++ | + | − | ∗ | ∗ | − | − | − | − | |

| PELD | − | − | + | ∗ | ∗ | − | − | + | ++ | − | ∗ | ∗ | + | − | − | − | |

| PET | + | + | + | + | − | − | + | − | − | − | + | ||||||

| PMMA | + | + | − | − | ∗ | ∗ | − | ++ | ∗ | − | + | ||||||

| POM | − | − | − | − | − | − | ∗ | ∗ | − | ++ | − | − | − | ||||

| PP | − | − | + | ∗ | − | − | − | − | + | ∗ | − | ++ | − | − | − | ||

| PS-HI | ∗ | − | + | − | − | − | − | − | − | − | − | − | − | ++ | − | − | |

| SAN | + | + | + | + | + | + | + | − | − | + | − | − | − | ++ | + | ||

| TPU | + | + | + | + | + | + | − | − | + | − | − | + | + | ||||

++ Pili maikaʻi, + Pili maikaʻi, ∗ Pili nāwaliwali, − ʻAʻohe pili.

EVA, Ethylene vinyl acetate; PA6, Polyamide 6; PA66, Polyamide 66; PBT, Polybutylene terephthalate; PEHD, Polyethylene kiʻekiʻe kiʻekiʻe; PELD, Polyethylene haʻahaʻa haʻahaʻa; POM, Polyoxymethylene; PS-HI, Polystyrene High Impact; SAN, Styrene Acrylonitrile; TPU, Thermoplastic polyurethane.

Nā ikaika pili o IML vs. IMD hōʻailona hōʻailona

ʻO ka hoʻohui ʻana i ke kaʻina hana hoʻonaninani me ke kaʻina hana e hoʻohui i ka lōʻihi, e hoʻemi i nā kumukūʻai hana a hana i ka maʻalahi o ka hoʻolālā.

Ka lōʻihi

ʻAʻole hiki ke hoʻoneʻe ʻia nā kiʻi me ka ʻole o ka luku ʻana i ka ʻāpana plastik a e hoʻomau mau i ke ola o ka ʻāpana. Loaʻa nā koho no ka hoʻomaikaʻi ʻana i ka lōʻihi ma nā wahi paʻakikī a me ke kūpaʻa kemika.

Kūʻai-pono

Hoʻopau ʻo IML i ka hōʻailona ʻana ma hope o ka hoʻoheheʻe ʻana, ka mālama ʻana a me ka mālama ʻana. Hoʻemi ia i ka waihona WIP a me ka manawa hou i koi ʻia no ka hoʻonaninani post-production, ma waho a i ʻole ka pūnaewele.

Hoʻolālā hoʻololi

Loaʻa ka IML ma kahi ākea o nā kala, nā hopena, nā mea leʻaleʻa a me nā koho kiʻi a hiki ke hoʻohālikelike i nā hiʻohiʻona paʻakikī loa e like me ke kila kila, nā hua lāʻau a me nā fiber carbon. Ke koi ʻia ka palapala hōʻoia UL, loiloi ʻia nā laʻana lepili i loko o ka mold e like me nā kūlana palekana like i hoʻohana ʻia no ka loiloi ʻana i nā lepili paʻakikī.