High definition Doe Injection Molding - Best In Mold Decoration supplier – FCE Detail:

CNC Machining Available Process

Professional Expertise and Guidance

Experienced team will help you on optimize molding part design, prototyping validation, recommendations whatever film or design improvement and production applications

Available Sample Checking

Production-level tool available with T1 samples delivered within 3weeks

Complicated Designs Acceptance

The narrow tolerance and 2D drawing acceptance to ensure closely match with your desired requirement with cost saving but quality guaranteed

IMD Sub Process

IML-In Mold Label

IML is a technique in which a pre-printed label is inserted into a mould immediately before moulding takes place. In this way ,fully printed parts can be produced at the end of the moulding process, without the need for a further difficult and expensive printing stage

IMF-In Mold Film

Roughly the same as IML but mainly used for 3D processing on top of IML. The process: Printing → forming → punching → inner plastic injection. It is widely used in molding for PC vacuum and high pressure , much suitable for high tensile products, 3D products

IMR-In Mold Roller

IMR is another IMD process to transfer the graphic on the part. Process steps: the film is sent into the mold and positioned, and then the drawing is transferred to the injection product after closing the mold. After opening the mold, the film is stripped and the product is pushed out.

Technical: fast production speed, stable yield, low cost, in line with the 3C industry demand change, short life cycle demand. Application products: mobile phones, digital cameras and 3C products.

In Mold Decoration Process Flow

Foil Printing

In-Mold Decoration film is printed by high speed gravure printing process. several layers(customized) of graphic color (max) also hard coat layer and adhesion layer are applied during this printing process

IMD molding

A foil feeder is installed on the injection machine. Foil film is then fed between the injection molding tool. Optical sensors in the feeder adjust registration of the film, and the ink printed on the film is transferred onto the plastic by the heat and pressure of injection molding

Product

After injection molding, the decorated products are available. No need 2nd process, unless UV cure HC is applied, there is a UV curing process

Technical Specification

| Printing method | Gravure printing, Silk screen printing |

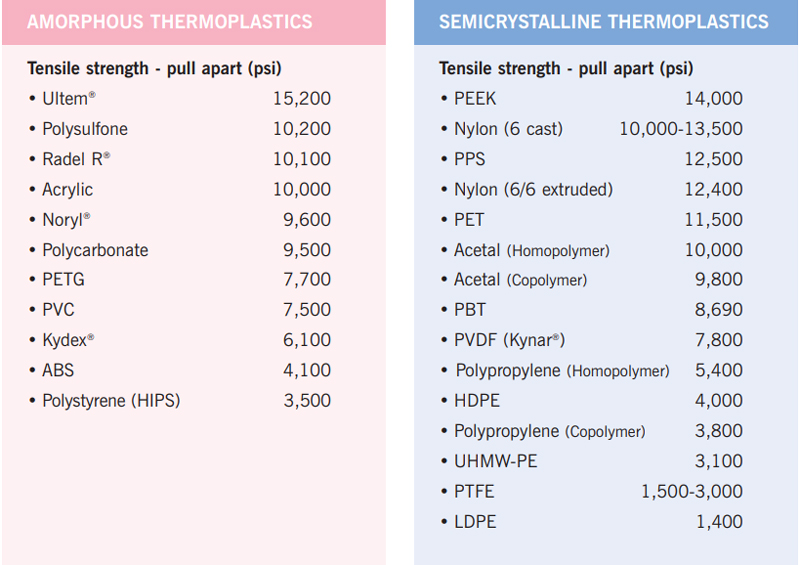

| Applicable material for injection molding | ABS, PC, PC, PBT+Glass fiber, PET, PC/ABS, PMMA, TPU, etc |

| Surface finish | High gloss, Mid matte, Low matte, Silky touch, Soft touch |

| Surface function | Hard Coating(Scratch resistance), UV shielding, Anti finger print |

| Other function | IR transmittance ink, Low conductive ink |

| IMD Applications | Two sides IMD, Two shots IMD, Inserts IMD |

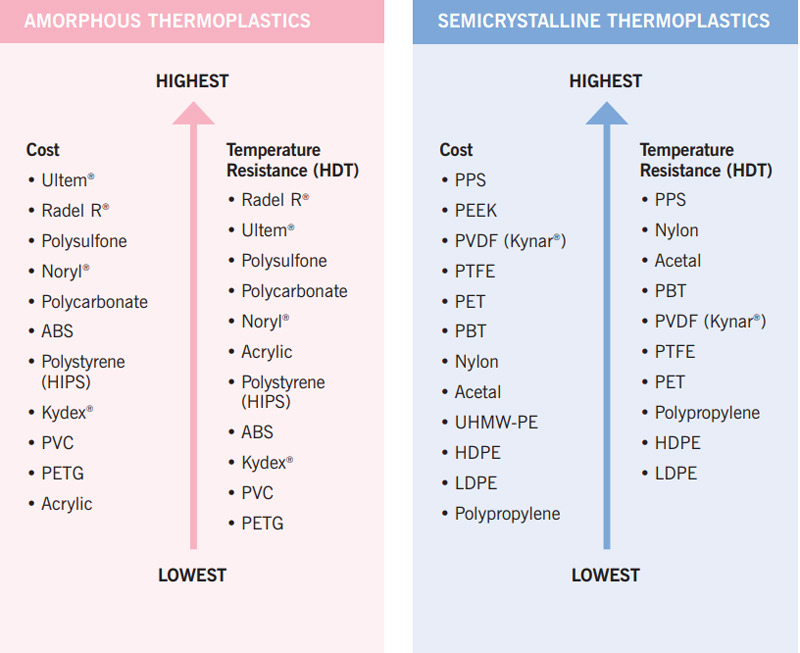

Material Selection

FCE will help you find best material according to the product requirement and application. There is a lot of choices in the market, we will also according the cost effective and supply chain stability to recommend the brand and grade of resins.

Key Benefits

Hard coat protection

Cosmetic surface protective to against scratch, chemical resistance but with Colorful surface

Decoration on Design Data

Surface decoration follow design data, since decoration is applied at the same time of injection molding process

Precise registration

The precision foil feeding system with optical sensor and +/-0.2mm precision control

High productivity roll feeder system

Foils and IMD molding is managed by roller system. Automotive and efficient production

Environmentally friendly

IMD ink is only applied onto the area where decoration is allowed. Friendly chemical components are used for environment protection

From Prototype to Production

Rapid Design Molds

Anticipated way for part design validation, low volume verification, steps for production

- No minimum quantities limited

- Lower cost design fitment checking

- Soft tool with hard steel

Production Tooling

Ideal for volume production parts, Tooling costs are higher than Rapid Design Molds, but allows for lower part pricing

- Up to 5M molding shots

- Multi-cavity tooling

- Automatic and monitoring

Typical Development Process

Quote with DFx

Check you requirement data and applications, provide scenarios quote with different suggestions. Simulation report with be provided in parallel

Review prototype (alternative)

Develop rapid tool (1~2wks) to mold prototype samples for design and molding process verification

Production mold development

You can kick off ramp up immediately with prototype tool. If the demand over millions, kick off production mold with multi-cavitation in parallel, which will take approx. 2~5weeks

Repeat Order

If you have focus for the demand, we can start delivery within 2days. No focus order, we can start partial shipment as few as 3days

In Mold Decoration FAQs

What are advantages of In Mold Decoration

- Extremely versatile uses

- Creates a completely sealed surface

- Works with a wide range of materials

- No need for secondary finishes

- Wide range of finishes can be included, including UV-stable

- Possibility to incorporate living switches

- No need for post-moulding labelling

- Work with spot color or full graphics

- Cost saving in the molding materials

What are applications of In Mold Decoration

- Decorative Trim and Accessories for OEM

- Decorative Trim and Accessories for Automotive

- Consumer Products (Cell Phone Cases, Electronics, Cosmetics)

- Variety of decorative plastic laminate combinations

- Custom manufacture to satisfy all of your requirements – price, durability and look

- Ability to quickly provide prototypes in small quantities for proof of concept and program approval for ultimate customer confidence

- Most chemical resistant cap in the industry is available for parts that must be extra durable

Product detail pictures:

Related Product Guide:

Sticking for the perception of Creating products of top quality and producing friends with people today from all around the world, we constantly place the desire of shoppers to start with for High definition Doe Injection Molding - Best In Mold Decoration supplier – FCE , The product will supply to all over the world, such as: Birmingham, Lisbon, Myanmar, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!