Ntxig Moulding

Engineering Expertise thiab Kev taw qhia

Pab neeg ua haujlwm engineering yuav pab koj ntawm kev txhim kho molding qhov tsim, GD&T kos, xaiv cov khoom siv. 100% xyuas kom meej cov khoom nrog siab ntau lawm feasibility, zoo, traceability

Simulation ua ntej Txiav Hlau

Rau txhua qhov projection, peb yuav siv pwm-ntws, Creo, Mastercam los simulate cov txheej txheem txhaj tshuaj molding, txheej txheem machining, txheej txheem kos duab los kwv yees qhov teeb meem ua ntej ua cov qauv ntawm lub cev.

Precise Complex Product Manufacturing

Peb muaj cov khoom lag luam zoo tshaj plaws hauv kev txhaj tshuaj molding, CNC machining thiab sheet hlau fabrication. Uas tso cai complex, siab precision yuav tsum tau cov khoom tsim

Hauv tsev txheej txheem

Kev txhaj tshuaj pwm ua, Txhaj tshuaj molding thiab txheej txheem thib ob ntawm cov ntaub ntawv luam tawm, kev kub hnyiab, kub stamping, sib dhos yog tag nrho hauv tsev, yog li koj yuav muaj tus nqi qis thiab txhim khu kev txhim kho lub sijhawm.

Ntxig Moulding

Ntxig molding yog txheej txheem kev txhaj tshuaj molding uas siv cov txheej txheem encapsulation ntawm cov khoom yas. Cov txheej txheem muaj ob kauj ruam tsim nyog.

Ua ntej, cov khoom tiav yog muab tso rau hauv pwm ua ntej txheej txheem molding tiag tiag yuav siv qhov chaw. Qhov thib ob, cov khoom siv yas molten yog nchuav rau hauv pwm; nws siv ib feem ntawm cov duab thiab cov pob qij txha nrog rau yav tas los ntxiv ib feem.

Ntxig molding tuaj yeem ua tau nrog ntau hom kev ntxig, cov ntaub ntawv yuav ua tau xws li:

- Hlau fasteners

- Tubes thiab studs

- Cov kabmob

- Cov khoom siv hluav taws xob

- Cov ntawv sau, kho kom zoo nkauj, thiab lwm yam khoom zoo nkauj

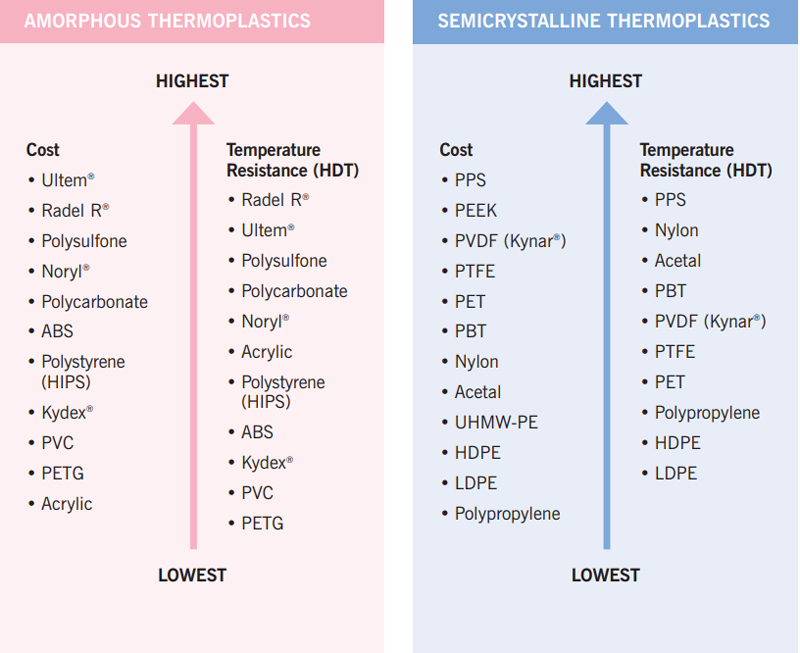

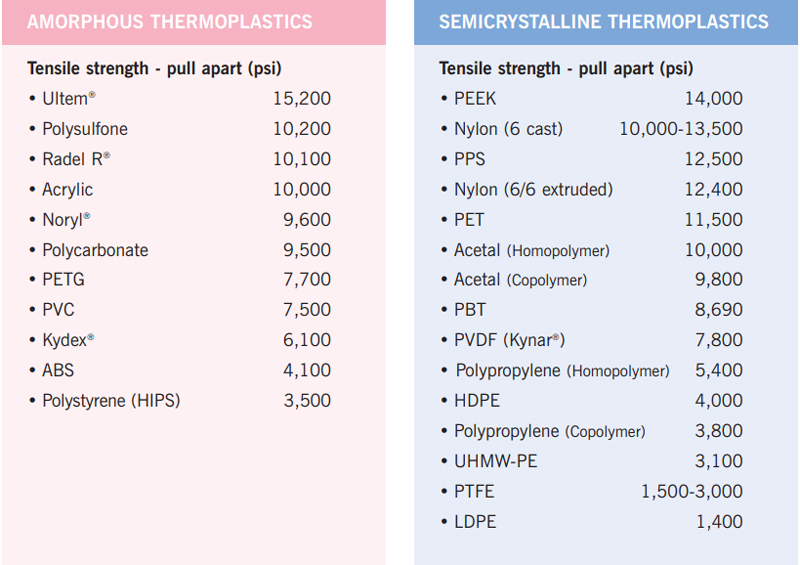

Kev xaiv khoom

FCE yuav pab koj nrhiav cov khoom zoo tshaj plaws raws li cov khoom xav tau thiab daim ntawv thov. Muaj ntau txoj kev xaiv nyob rau hauv kev ua lag luam, peb tseem yuav ua raws li tus nqi zoo thiab cov saw hlau ruaj khov kom pom zoo rau hom thiab qib ntawm resins.

Moulded ib feem Finishes

| Glossy | Semi-Glossy | Matte | Textured |

| SPI-A0 | SPI-B1 | SPI-C1 | MT (Moldtech) |

| SPI-A1 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| SPI-A2 | SPI-B3 | SPI-C3 | YS (Yick Sang) |

| SPI-A3 |

Ua kom tsim tau yooj yim

Ntxig molding tso cai rau cov neeg tsim qauv thiab cov chaw tsim khoom ua kom txhua yam ntawm cov duab lossis cov qauv tsim uas lawv xav tau

Txo cov nqi sib dhos thiab kev ua haujlwm

Muab ob peb yam sib cais rau hauv ib qho kev txhaj tshuaj molding, ua kom muaj txiaj ntsig zoo dua. Nrog kev txhaj tshuaj molding yog cov txheej txheem ib-kauj ruam, txo qis cov kauj ruam sib dhos thiab cov nqi zog

Ua kom muaj kev ntseeg siab

Melted yas ntws ywj siab nyob ib ncig ntawm txhua qhov ntxig ua ntej txias thiab mus tas li, qhov ntxig yog ruaj khov rau hauv cov yas

Txo qhov loj thiab qhov hnyav

Ntxig molding tsim cov khoom yas uas me dua thiab sib dua hauv qhov hnyav, txawm tias ua haujlwm zoo thiab txhim khu kev qha ntau dua li cov khoom yas ua nrog lwm txoj hauv kev.

Ntau yam khoom siv

Ntxig molding yog txheej txheem uas tuaj yeem siv ntau hom yas resins, xws li cov thermoplastics ua haujlwm siab

Los ntawm Prototype mus rau Production

Rapid Design Pwm

Txoj kev npaj rau kev tsim ib feem validation, tsawg ntim pov thawj, cov kauj ruam rau ntau lawm

- Tsis muaj qhov tsawg kawg nkaus txwv

- Tsawg tus nqi tsim haum kuaj xyuas

- Nyuaj tsim txais

Cov cuab yeej siv ntau lawm

Qhov zoo tshaj plaws rau ntim cov khoom ntim, Tooling cov nqi siab dua Rapid Design Moulds, tab sis tso cai rau tus nqi qis dua

- Txog li 5M molding txhaj tshuaj

- Multi-cavity tooling

- Tsis siv neeg thiab saib xyuas

Txheej txheem kev loj hlob

Quote nrog DFx

Tshawb xyuas koj cov ntaub ntawv xav tau thiab cov ntawv thov, muab cov xwm txheej hais nrog cov lus qhia sib txawv. Simulation daim ntawv qhia nrog yuav muab nyob rau hauv parallel

Tshawb nrhiav tus qauv (alternative)

Tsim cov cuab yeej ceev (1 ~ 2wks) rau pwm qauv qauv rau kev tsim thiab molding txheej txheem pov thawj

Kev tsim pwm tsim

Koj tuaj yeem ncaws tawm ramp tam sim ntawd nrog cov cuab yeej qauv. Yog hais tias qhov kev thov ntau tshaj lab, ncaws tawm pwm ntau lawm nrog ntau-cavitation nyob rau hauv parallel, uas yuav siv approx. 2 ~ 5 lub lis piam

Rov hais dua

Yog tias koj muaj kev tsom mus rau qhov kev thov, peb tuaj yeem pib xa khoom hauv 2 hnub. Tsis muaj kev txiav txim siab, peb tuaj yeem pib xa khoom ib nrab li ob peb hnub

Ntxig Moulding FAQs

Insert molding daim ntawv thov

- Knobs rau cov khoom siv, tswj thiab sib dhos

- Encapsulated cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob

- Threaded screws

- Encapsulated bushings, raj, studs, thiab muab tso tawm

- Cov cuab yeej kho mob thiab cov cuab yeej siv

Qhov txawv ntawm Insert Molding & Overmolding yog dab tsi

Ntxig molding tsuas yog ib qho ntawm cov txheej txheem siv los pwm yas nyob ib ncig ntawm cov khoom tsis yog yas.

Hauv cov ntsiab lus yooj yim, qhov sib txawv ntawm qhov tseem ceeb yog cov kauj ruam uas yuav tsum tau ua kom tiav qhov kawg.

Ntawm qhov tod tes, Insert molding ua tib yam, tab sis tsuas yog hauv ib kauj ruam xwb. Qhov txawv yog nyob rau hauv txoj kev uas cov khoom kawg yog ua. Ntawm no, cov khoom ntxig thiab molten yog nyob rau hauv pwm los tsim cov khoom ua ke kawg.

Ib qho tseem ceeb ntawm qhov sib txawv yog tias kev txhaj tshuaj molding tsis yog khi los ntawm cov yas, nrog rau cov hlau nrog cov khoom sib txawv

Overmolding feem ntau yog siv los tsim cov khoom lag luam nrog cov khoom zoo nkauj, cov duab, thiab xim, feem ntau ua rau txee rov hais dua. Ntxig molding yog siv los tsim cov khoom nruj dua.