Hauv Pwm Kho Kom Zoo Nkauj

CNC Machining muaj txheej txheem

Kev txawj ntse thiab kev taw qhia

Pab neeg muaj kev paub dhau los yuav pab koj ntawm kev txhim kho molding ib feem tsim, prototyping validation, cov lus pom zoo txawm tias zaj duab xis lossis tsim kev txhim kho thiab kev siv ntau lawm

Muaj Kev Tshawb Fawb

Ntau lawm-theem cov cuab yeej muaj nrog T1 cov qauv xa hauv 3 lub lis piam

Nyuaj Tsim Txais Txais

Qhov nqaim siab ntev thiab 2D kos duab lees paub los ua kom zoo sib xws nrog koj qhov kev xav tau nrog tus nqi txuag tab sis zoo lav

IMD Sub Process

IML-hauv Mould Label

IML yog cov txheej txheem uas cov ntawv sau ua ntej tau muab tso rau hauv pwm tam sim ua ntej molding yuav tshwm sim. Nyob rau hauv txoj kev no, tag nrho cov khoom luam tawm tuaj yeem tsim tau thaum kawg ntawm cov txheej txheem molding, tsis tas yuav tsum muaj qhov nyuaj thiab kim luam ntawv theem.

IMF-Nyob hauv Mould Film

Zoo ib yam li IML tab sis feem ntau yog siv rau kev ua 3D nyob rau sab saum toj ntawm IML. Cov txheej txheem: Printing → sib sau → xuas nrig ntaus → puab yas txhaj tshuaj. Nws yog dav siv nyob rau hauv molding rau PC lub tshuab nqus tsev thiab siab siab, ntau haum rau high tensile khoom, 3D khoom

IMR-hauv Mould Roller

IMR yog lwm cov txheej txheem IMD los hloov cov duab ntawm ib feem. Cov txheej txheem txheej txheem: cov yeeb yaj kiab raug xa mus rau hauv pwm thiab muab tso rau, thiab tom qab ntawd cov duab kos raug xa mus rau cov khoom txhaj tshuaj tom qab kaw cov pwm. Tom qab qhib pwm, zaj duab xis yog stripped thiab cov khoom raug thawb tawm.

Technical: ceev ceev ntau lawm, ruaj khov tawm los, tus nqi qis, nyob rau hauv txoj kab nrog 3C kev lag luam xav tau hloov, luv luv lub neej xav tau. Cov khoom siv: cov xov tooj ntawm tes, cov koob yees duab digital thiab 3C cov khoom.

Nyob rau hauv Mould Decoration Process Flow

Ntawv Nyiaj Luam Ntawv

Nyob rau hauv-Mold Decoration zaj duab xis yog luam tawm los ntawm kev kub ceev gravure printing txheej txheem. ob peb txheej (customized) ntawm graphic xim (max) kuj nyuaj txheej txheej thiab adhesion txheej yog siv rau lub sij hawm no printing txheej txheem

IMD txhaj tshuaj molding

Ib qho foil feeder yog ntsia rau ntawm lub tshuab txhaj tshuaj. Tom qab ntawv cov yeeb yaj kiab yog pub ntawm cov cuab yeej txhaj tshuaj molding. Optical sensors nyob rau hauv feeder kho cov ntawv sau npe ntawm zaj duab xis, thiab tus number case luam tawm ntawm zaj duab xis yog xa mus rau cov yas los ntawm tshav kub thiab siab ntawm kev txhaj tshuaj molding

Khoom

Tom qab txhaj tshuaj molding, cov khoom dai kom zoo nkauj muaj. Tsis xav tau txheej txheem thib 2, tshwj tsis yog UV kho HC tau thov, muaj txheej txheem UV kho

Technical Specification

| Txoj kev luam ntawv | Gravure printing, Silkscreen luam ntawv |

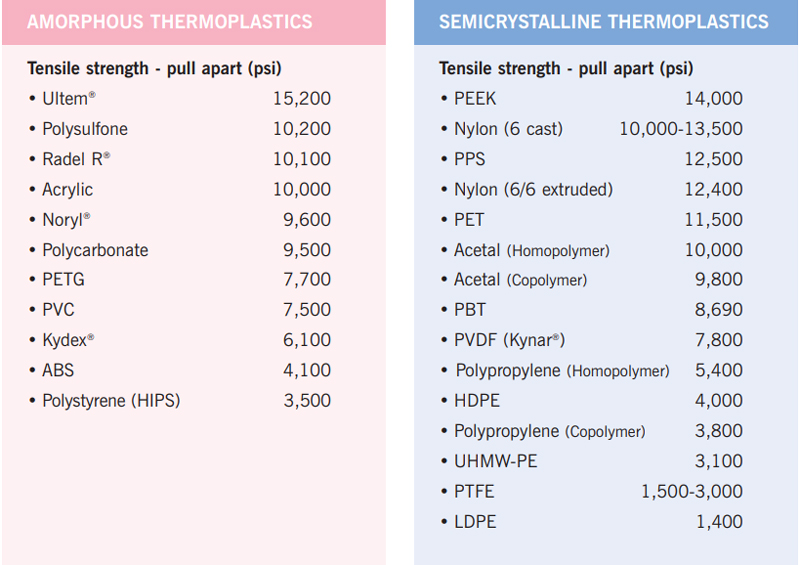

| Cov khoom siv rau kev txhaj tshuaj molding | ABS, PC, PC, PBT + iav fiber ntau, PET, PC / ABS, PMMA, TPU, thiab lwm yam |

| Nto tiav | High gloss, Mid matte, Tsawg matte, Silky kov, Mos kov |

| Nto muaj nuj nqi | Hard Txheej (Scratch resistance), UV shielding, Anti ntiv tes luam |

| Lwm txoj haujlwm | IR transmittance number case, Tsawg conductive number case |

| Cov ntawv thov IMD | Ob sab IMD, Ob qhov txhaj tshuaj IMD, Ntxig IMD |

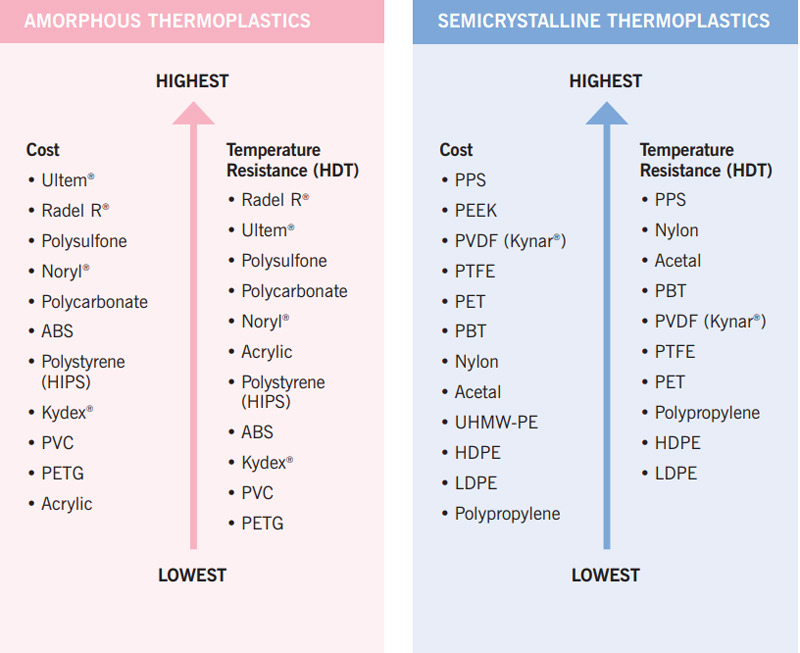

Kev xaiv khoom

FCE yuav pab koj nrhiav cov khoom zoo tshaj plaws raws li cov khoom xav tau thiab daim ntawv thov. Muaj ntau txoj kev xaiv nyob rau hauv kev ua lag luam, peb tseem yuav ua raws li tus nqi zoo thiab cov saw hlau ruaj khov kom pom zoo rau hom thiab qib ntawm resins.

Cov txiaj ntsig tseem ceeb

Kev tiv thaiv tawv tawv

Cosmetic nto tiv thaiv kev khawb, tshuaj tiv thaiv tab sis nrog Xim Xim

Kho kom zoo nkauj ntawm Design Data

Deg kho kom zoo nkauj ua raws cov ntaub ntawv tsim, txij li kev kho kom zoo nkauj yog siv tib lub sijhawm ntawm kev txhaj tshuaj molding txheej txheem

Precise sau npe

Lub precision foil pub system nrog optical sensor thiab +/- 0.2mm precision tswj

High productivity yob feeder system

Foils thiab IMD molding yog tswj los ntawm cov menyuam qhov system. Automotive thiab ntau lawm

Ib puag ncig tus phooj ywg

IMD number case tsuas yog siv rau ntawm thaj chaw uas tso cai rau kho kom zoo nkauj. Cov tshuaj lom neeg zoo yog siv rau kev tiv thaiv ib puag ncig

Los ntawm Prototype mus rau Production

Rapid Design Pwm

Txoj kev npaj rau kev tsim ib feem validation, tsawg ntim pov thawj, cov kauj ruam rau ntau lawm

- Tsis muaj qhov tsawg kawg nkaus txwv

- Tsawg tus nqi tsim haum kuaj xyuas

- Cov cuab yeej mos nrog cov hlau tawv

Cov cuab yeej siv ntau lawm

Qhov zoo tshaj plaws rau ntim cov khoom ntim, Tooling cov nqi siab dua Rapid Design Moulds, tab sis tso cai rau tus nqi qis dua

- Txog li 5M molding txhaj tshuaj

- Multi-cavity tooling

- Tsis siv neeg thiab saib xyuas

Txheej txheem kev loj hlob

Quote nrog DFx

Tshawb xyuas koj cov ntaub ntawv xav tau thiab cov ntawv thov, muab cov xwm txheej hais nrog cov lus qhia sib txawv. Simulation daim ntawv qhia nrog yuav muab nyob rau hauv parallel

Tshawb nrhiav tus qauv (alternative)

Tsim cov cuab yeej ceev (1 ~ 2wks) rau pwm qauv qauv rau kev tsim thiab molding txheej txheem pov thawj

Kev tsim pwm tsim

Koj tuaj yeem ncaws tawm ramp tam sim ntawd nrog cov cuab yeej qauv. Yog hais tias qhov kev thov ntau tshaj lab, ncaws tawm pwm ntau lawm nrog ntau-cavitation nyob rau hauv parallel, uas yuav siv approx. 2 ~ 5 lub lis piam

Rov hais dua

Yog tias koj muaj kev tsom mus rau qhov kev thov, peb tuaj yeem pib xa khoom hauv 2 hnub. Tsis muaj kev txiav txim siab, peb tuaj yeem pib xa khoom ib nrab li ob peb hnub

Hauv Pwm Kho Kom Zoo Nkauj FAQs

Dab tsi yog qhov zoo ntawm Hauv Pwm Kho Kom Zoo Nkauj

- Kev siv ntau yam heev

- Tsim kom muaj qhov ntim tag nrho

- Ua haujlwm nrog ntau yam khoom siv

- Tsis xav tau kev ua tiav theem nrab

- Ntau qhov kev ua tiav tuaj yeem suav nrog, suav nrog UV-ruaj khov

- Muaj peev xwm muab cov keyboards nyob

- Tsis xav tau cov ntawv sau tom qab molding

- Ua haujlwm nrog cov xim xim lossis cov duab tag nrho

- Kev txuag nyiaj hauv cov khoom siv molding

Dab tsi yog daim ntawv thov ntawm Hauv Pwm Kho Kom Zoo Nkauj

- Kho kom zoo nkauj Trim thiab Accessories rau OEM

- Kho kom zoo nkauj Trim thiab Accessories rau Automotive

- Cov khoom siv (cov xov tooj ntawm tes, Electronics, Tshuaj pleev ib ce)

- Ntau yam ntawm cov hniav yas laminate ua ke

- Kev tsim khoom tsim los ua kom tau raws li koj qhov yuav tsum tau ua - nqe, durability thiab saib

- Muaj peev xwm sai sai muab cov qauv me me rau cov ntaub ntawv pov thawj ntawm lub tswv yim thiab kev pom zoo rau cov neeg siv khoom siab kawg

- Feem ntau cov tshuaj resistant cap nyob rau hauv kev lag luam yog muaj rau cov khoom uas yuav tsum tau ntxiv check