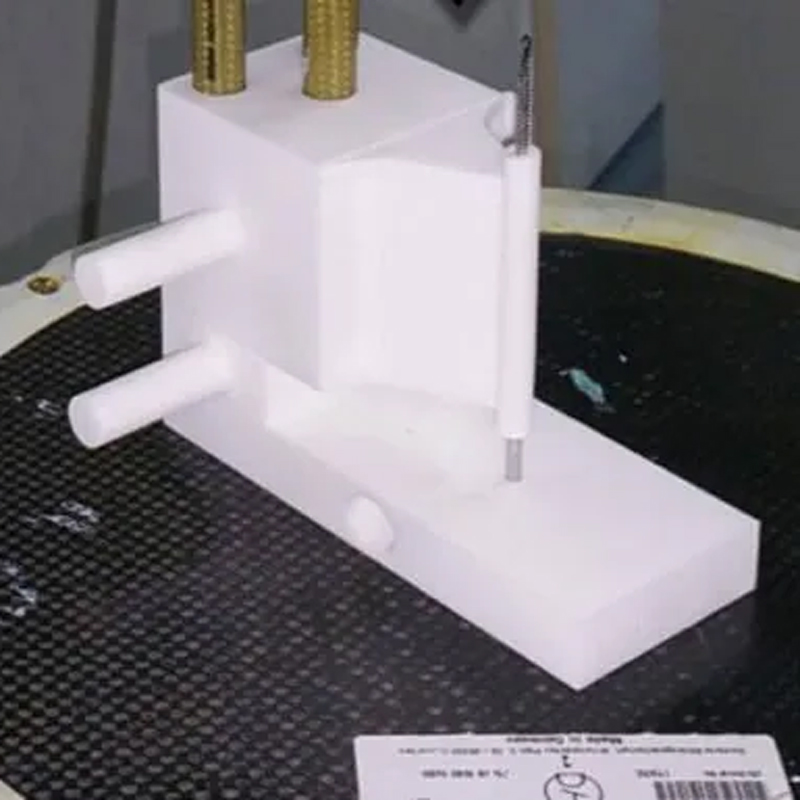

SLA

SLA Design Guide

Kev daws teeb meem luam ntawv

Txheem txheej thickness: 100 µm Qhov tseeb: ± 0.2% (nrog qis qis ntawm ± 0.2 hli)

Qhov loj txwv 144 x 144 x 174 hli Yam tsawg kawg nkaus thickness Yam tsawg kawg nkaus phab ntsa thickness 0.8 hli – Nrog ib tug 1: 6 piv

Etching thiab Embossing

Yam tsawg kawg nkaus qhov siab thiab dav cov ntsiab lus Embossed: 0.5 hli

Engraved: 0.5 hli

Npog & interlocking ntim

Qhov chaw nyob? Tsis pom zoo Interlocking qhov chaw? Tsis pom zoo

Daim ntawv sib dhos txwv

Kev sib dhos? Tsis muaj

Engineering Expertise thiab Kev taw qhia

Pab neeg ua haujlwm engineering yuav pab koj ntawm kev txhim kho molding qhov tsim, GD&T kos, xaiv cov khoom siv. 100% xyuas kom meej cov khoom nrog siab ntau lawm feasibility, zoo, traceability

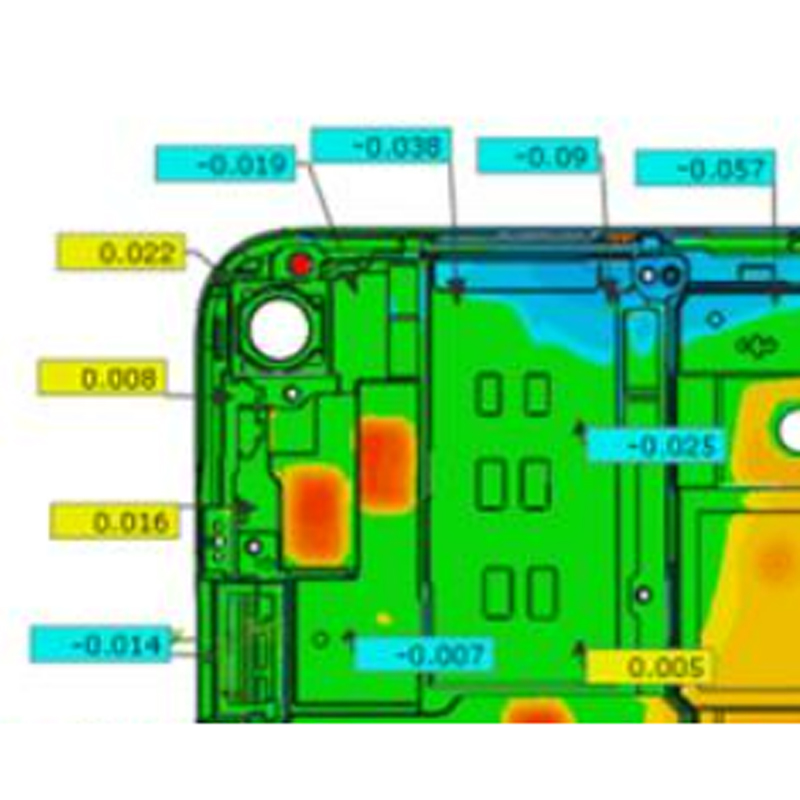

Simulation ua ntej Txiav Hlau

Rau txhua qhov projection, peb yuav siv pwm-ntws, Creo, Mastercam los simulate cov txheej txheem txhaj tshuaj molding, txheej txheem machining, txheej txheem kos duab los kwv yees qhov teeb meem ua ntej ua cov qauv ntawm lub cev.

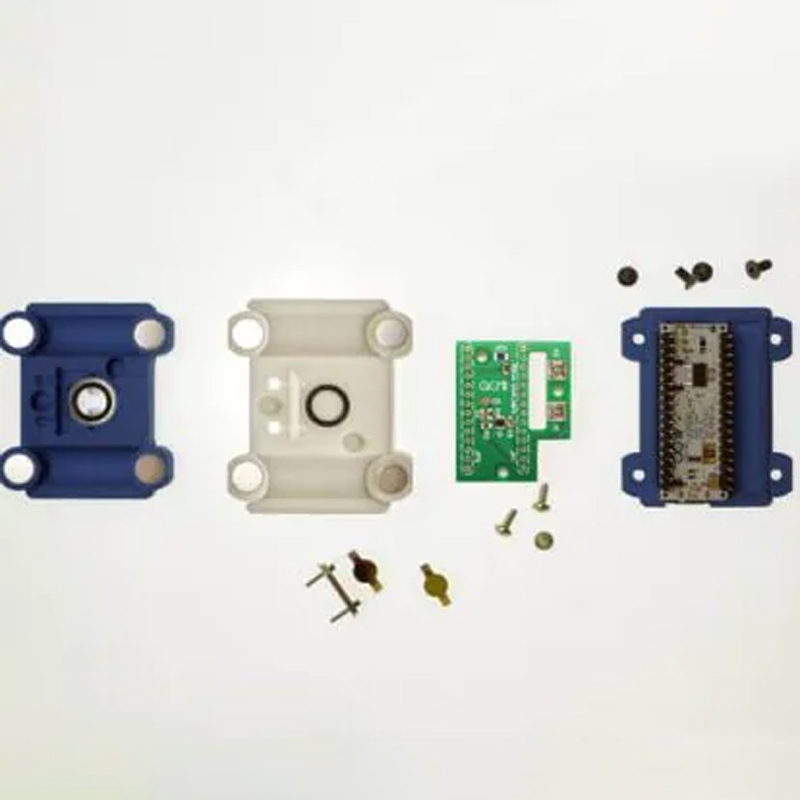

Complex Product Design

Peb muaj cov khoom lag luam zoo tshaj plaws hauv kev txhaj tshuaj molding, CNC machining thiab sheet hlau fabrication. Uas tso cai complex, siab precision yuav tsum tau cov khoom tsim

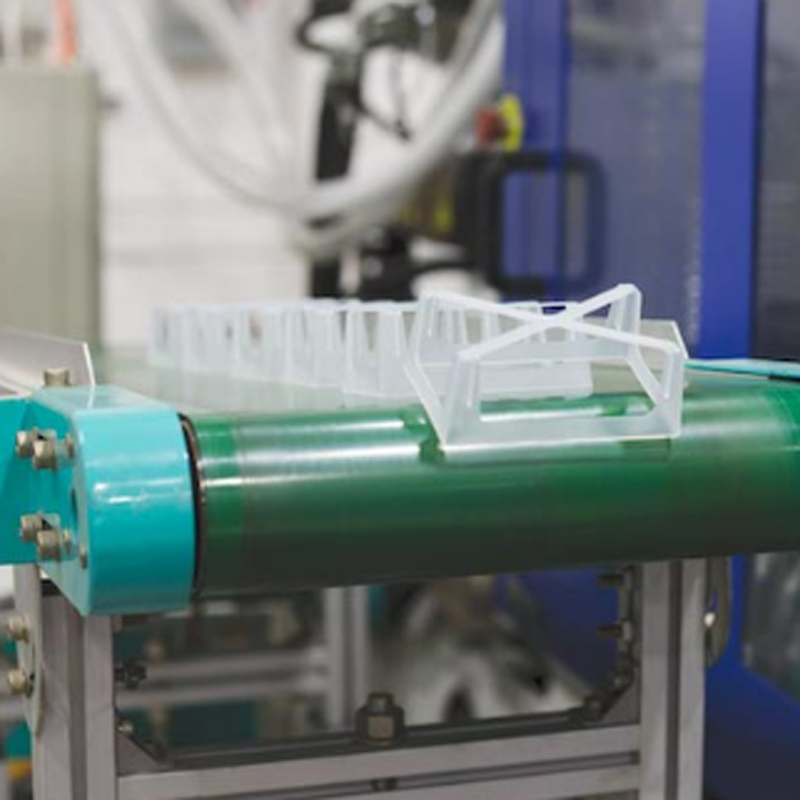

Hauv tsev txheej txheem

Kev txhaj tshuaj pwm ua, Txhaj tshuaj molding thiab txheej txheem thib ob ntawm cov ntaub ntawv luam tawm, kev kub hnyiab, kub stamping, sib dhos yog tag nrho hauv tsev, yog li koj yuav muaj tus nqi qis thiab txhim khu kev txhim kho lub sijhawm.

Cov txiaj ntsig ntawm SLA Printing

Qib siab ntawm cov ntsiab lus

Yog tias koj xav tau qhov tseeb, SLA yog cov txheej txheem tsim khoom ntxiv uas koj xav tau los tsim cov qauv qhia ntxaws heev

Ntau yam kev siv

Los ntawm tsheb mus rau cov neeg siv khoom, ntau lub tuam txhab siv Stereolithography rau kev tsim qauv sai

Tsim kev ywj pheej

Tsim-tsav manufacturing tso cai rau koj los tsim cov geometry complex

Daim ntawv thov SLA

Automotive

Kev kho mob thiab kho mob

Mechanics

High Tech

Cov khoom lag luam

Electronics

SLA vs SLS vs FDM

| Lub Npe | Stereolithography | Selective Laser Sintering | Fused Deposition Modeling |

| Cov ntawv luv | SLA | SLS | FDM |

| Hom khoom | Liquid (Photopolymer) | Hmoov (Polymer) | Khoom (Filaments) |

| Khoom siv | Thermoplastics (Elastomers) | Thermoplastics xws li Nylon, Polyamide, thiab Polystyrene; Elastomers; Composites | Thermoplastics xws li ABS, Polycarbonate, thiab Polyphenylsulfone; Elastomers |

| Max qhov loj me (hauv.) | 59.00 x 29.50 x 19.70 Nws | 22.00 x 22.00 x 30.00 Nws | 36.00 x 24.00 x 36.00 Nws |

| Min feature loj (hauv.) | 0.004 ib | 0.005 ib | 0.005 ib |

| Min txheej thickness (hauv.) | 0.0010 Nws | 0.0040 Nws | 0.0050 Nws |

| Tolerance (hauv.) | ± 0.0050 | ± 0.0100 | ± 0.0050 |

| Nto tiav | du | Nruab nrab | Rough |

| Tsim kom ceev | Nruab nrab | Ceev ceev | qeeb |

| Daim ntawv thov | Daim ntawv / haum kuaj, Kev sim ua haujlwm, cov qauv siv nrawm nrawm, Snap fits, Cov ncauj lus kom ntxaws heev, nthuav qhia qauv, kev siv kub kub | Kev xeem daim ntawv / haum, Kev sim ua haujlwm, cov qauv siv ceev ceev, Cov ncauj lus kom ntxaws tsawg dua, Cov khoom siv nrog snap-fits & nyob hinges, Kev siv kub kub | Kev xeem daim ntawv / haum, kev xeem ua haujlwm, cov qauv siv ceev ceev, cov ncauj lus kom ntxaws me me, kev nthuav qhia cov qauv, cov neeg mob thiab cov ntawv thov zaub mov, kev siv kub kub |

SLA Advantage

Stereolithography yog ceev

Stereolithography yog qhov tseeb

Stereolithography Ua haujlwm nrog cov khoom sib txawv

Sustainability

Multi-Part Assemblies muaj peev xwm

Texturing muaj peev xwm