Kev cai Sheet Hlau txoj kev

Icons

Kev txhawb nqa engineering

Pab neeg ua haujlwm engineering yuav qhia lawv cov kev paub dhau los, pab txhawb kev tsim kho ib feem, GD&T kos, xaiv cov khoom siv. Guarantee cov khoom feasibility thiab zoo

Kev xa khoom sai

Ntau tshaj 5000+ cov khoom siv hauv Tshuag, 40+ tshuab los txhawb koj qhov kev thov loj. Qauv xa tuaj tsawg li ib hnub

Txais kev tsim qauv

Peb muaj cov khoom lag luam saum toj kawg nkaus laser txiav, khoov, pib vuam thiab tshuaj xyuas chaw. Uas tso cai complex, siab precision yuav tsum tau cov khoom tsim

Hauv tsev 2nd txheej txheem

Hmoov txheej rau cov xim sib txawv thiab ci ntsa iab, Pad / screen luam ntawv thiab kub stamping rau cov cim, riveting thiab vuam txawm tias lub thawv tsim los ua ke

Sheet Hlau txheej txheem

FCE daim ntawv hlau txoj kev pabcuam kev sib koom ua ke khoov, yob txoj kev, sib sib zog nqus nqus, ncab txoj kev ua haujlwm hauv ib lub rooj cob qhia. Koj tuaj yeem tau txais cov khoom tiav nrog cov khoom zoo thiab lub sijhawm luv luv.

Khoov

dabtsi yog khoov yog txheej txheem hlau uas siv lub zog rau ib daim ntawv hlau, ua rau nws khoov ntawm lub kaum sab xis thiab tsim cov duab uas xav tau. Kev ua haujlwm dabtsi yog khoov ua rau deformation raws ib lub axis, tab sis ib ntus ntawm ntau qhov kev ua haujlwm sib txawv tuaj yeem ua tau los tsim ib qho nyuaj. Bent qhov chaw tuaj yeem ua tau me me, xws li bracket, xws li lub thawv loj lossis chassis

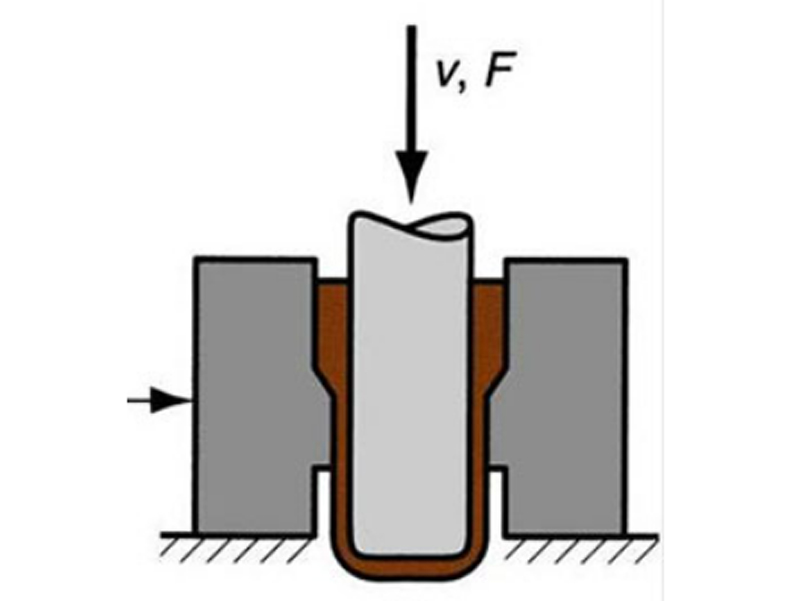

Yob txoj kev

Roll forming, yog cov txheej txheem hlau ua haujlwm uas cov ntawv hlau ua tau zoo zuj zus los ntawm kev ua haujlwm dabtsi. Cov txheej txheem yog ua nyob rau ntawm ib tug yob txoj kab. Txhua qhov chaw nres tsheb muaj cov menyuam, hu ua cov menyuam tuag, nyob ntawm ob sab ntawm daim ntawv. Cov duab thiab qhov loj ntawm cov menyuam tuag yuav yog qhov tshwj xeeb rau qhov chaw nres tsheb, lossis ob peb qhov zoo tib yam rau cov menyuam tuag tuaj yeem siv rau ntau txoj haujlwm. Cov menyuam tuag tuaj yeem nyob saum toj thiab hauv qab daim ntawv, nyob rau sab, ntawm lub kaum sab xis, thiab lwm yam. cov menyuam tuag yog lubricated kom txo kev sib txhuam ntawm cov tuag thiab cov ntawv, yog li txo cov cuab yeej hnav.

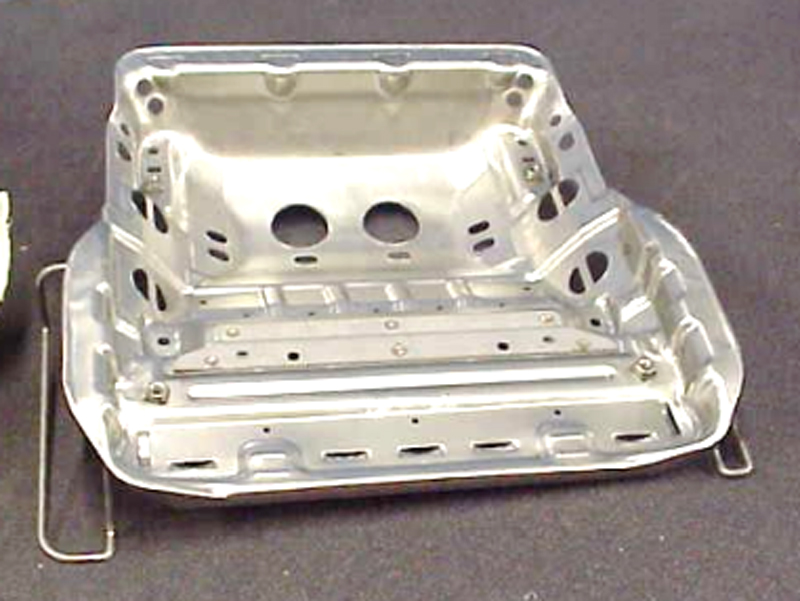

Daim duab sib sib zog nqus

Sib sib zog nqus daim duab yog ib daim ntawv hlau ua txheej txheem nyob rau hauv uas cov ntawv hlau yog tsim rau hauv qhov xav tau ib feem zoo los ntawm cov cuab yeej kos duab. Ib tug txiv neej lub cuab tam thawb ib daim ntawv hlau downward nws mus rau hauv ib tug tuag kab noj hniav nyob rau hauv cov duab ntawm tus tsim ib feem. Lub zog tensile thov rau ntawm cov ntawv hlau ua rau nws ua rau plastically deform rau hauv lub khob zoo li ib feem. Kev kos duab sib sib zog nqus yog dav siv nrog cov khoom siv hlau, xws li txhuas, tooj dag, tooj liab, thiab cov hlau me me. Daim ntawv thov sib sib zog nqus nqus yog lub cev tsheb thiab roj tso tsheb hlau luam, cov kaus poom, khob, chav ua noj dab dej, lauj kaub thiab lauj kaub.

Kev kos duab rau cov duab tsis yooj yim

Dhau li ntawm kev sib sib zog nqus nqus, FCE kuj muaj kev paub txog ntawm cov ntawv hlau ua haujlwm nyuaj. Finite element tsom xam kom pab tau qhov zoo ntawm qhov kev sim thawj zaug.

Ironing

Cov ntawv hlau tuaj yeem raug ironed kom tau txais cov tuab tuab. Piv txwv li, los ntawm cov txheej txheem no koj tuaj yeem muaj cov khoom thinner nyob rau sab phab ntsa. Tab sis cov tuab nyob hauv qab. Daim ntawv thov yog cov kaus poom, khob.

Muaj Cov Khoom Siv rau cov ntawv hlau fabrication

FCE npaj 1000+ cov khoom siv hauv Tshuag rau kev hloov pauv sai tshaj plaws, Peb cov khoom siv kho tshuab yuav pab koj xaiv cov khoom siv, kev tshuaj xyuas tshuab, kev ua tau zoo

| Aluminium | Tooj | Bronze | Hlau |

| Aluminium 5052 | tooj 101 | Bronze 220 | Stainless hlau 301 |

| Aluminium 6061 | Tooj 260 (Brass) | Bronze 510 | Stainless hlau 304 |

| Tooj C110 | Stainless hlau 316/316L | ||

| Hlau, Tsawg Carbon |

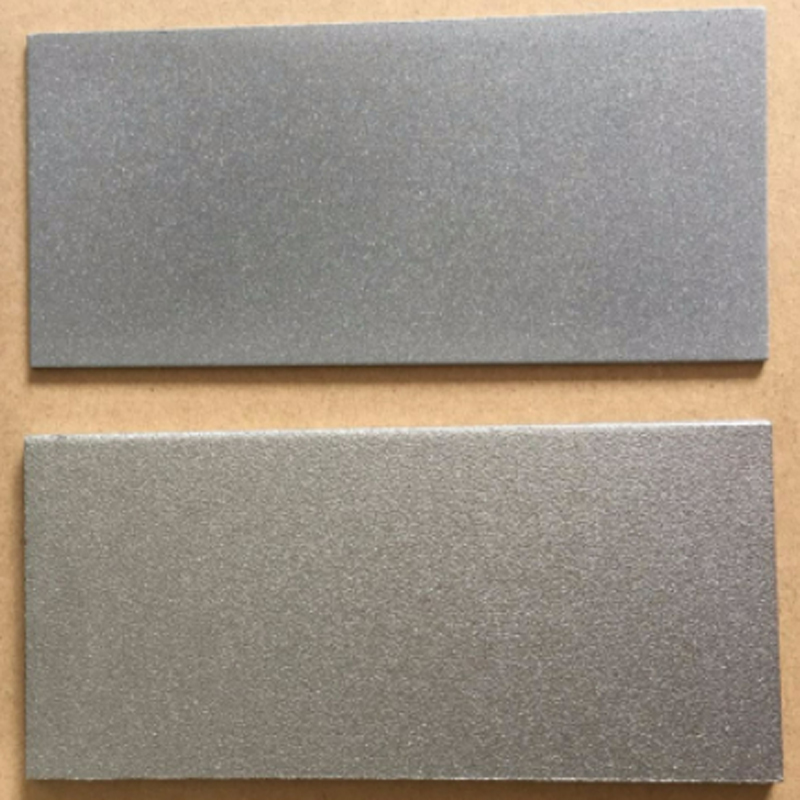

Nto tiav

FCE muaj ntau yam ntawm cov txheej txheem kho saum npoo. Electroplating, hmoov txheej, anodizing tuaj yeem kho raws li xim, kev ntxhib los mos thiab ci ntsa iab. Qhov tsim nyog tiav tuaj yeem pom zoo raws li kev ua haujlwm.

txhuam hniav

Kev tawg

Polishing

Anodizing

Hmoov Txheej

Kub Hloov

Plating

Printing & Laser Mark

Peb Kev cog lus zoo

General FAQs

Sheet Hlau Fabrication yog dab tsi?

Sheet hlau fabrication yog cov txheej txheem tsim tawm uas txiav lossis / thiab ua cov khoom los ntawm cov ntawv hlau. Cov ntawv hlau feem ntau tau siv rau kev ua haujlwm siab thiab ua haujlwm ntev, cov ntawv thov raug siv yog chassis, enclosures, thiab brackets.

Sheet Hlau Forming yog dab tsi?

Sheet hlau txoj kev ua cov txheej txheem yog cov uas quab yuam siv rau cov ntawv hlau los hloov nws cov duab es tsis yog tshem tawm cov khoom. Lub zog siv zog ua rau cov hlau dhau ntawm nws lub zog tawm los, ua rau cov khoom siv rau plastically deform, tab sis tsis tawg. Tom qab lub zog tso tawm, daim ntawv yuav rov qab me ntsis, tab sis qhov tseem ceeb khaws cov duab raws li nias.

Dab tsi yog hlau stamping?

Txhawm rau ua kom cov ntawv hlau tsim ua haujlwm tau zoo, Hlau stamping tuag yog siv los hloov cov ntawv hlau ca rau hauv cov duab tshwj xeeb. Nws yog cov txheej txheem nyuaj uas tuaj yeem suav nrog ntau cov txheej txheem hlau - blanking, xuas nrig ntaus, khoov thiab tho.

Lub sijhawm them nyiaj yog dab tsi?

Cov neeg siv khoom tshiab, 30% them ua ntej. Sib npaug qhov seem ua ntej xa khoom. Kev txiav txim tsis tu ncua, peb lees txais peb lub hlis them nqi