3D Printing Service

Prompt Quotes & Manufacture Feasibility Feedback

Xa koj tus qauv tsim rau kuv kom tau txais tus nqi tam sim thiab tsim cov lus qhia ua tau, muaj kev paub dhau los rov qab los rau koj tus nqi sib tw

Cov qauv luam tawm nrawm los ntawm Prototype mus rau Kev Tsim Khoom

Ceev thiab muaj peev xwm muaj peev xwm ua tau raws li koj qhov yuav tsum tau ua txhua lub sijhawm lossis xaj xaj los ntawm cov qauv mus rau ntau lawm

Order Tracking & Quality Control

Tsis txhob txhawj txog qhov twg koj qhov chaw nyob, cov xwm txheej niaj hnub hloov tshiab nrog cov yeeb yaj kiab thiab cov duab tuaj yeem ua kom koj ib txwm tsom mus rau. Lub sijhawm tiag tiag los qhia koj txog qhov zoo nws yog dab tsi

Hauv tsev 2nd txheej txheem

Kev pleev xim rau cov xim sib txawv thiab ci ntsa iab, Pad luam ntawv lossis ntxig molding thiab sub sib dhos xws li silicon tuaj yeem siv tau

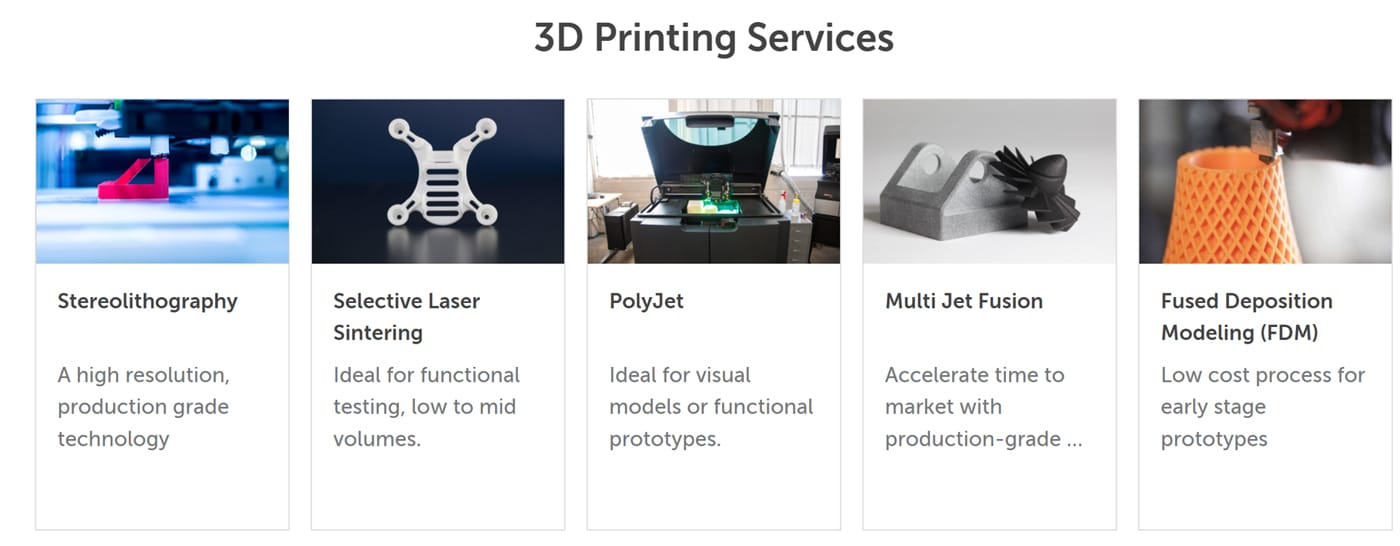

Ntau sub 3D luam tawm cov txheej txheem sib txawv yog siv hauv peb cov nroj tsuag hais txog cov ntaub ntawv yas & hlau. Txhua qhov kev xaiv uas siv tau ntawm kev txuag nqi & kev ua haujlwm lav yog nyob ntawm koj qhov yuav tsum tau ua.

Duab

FDM (Fused Deposition Modeling)

Tus nqi qis dua txheej txheem luam ntawv rau cov qauv ua ntej kev tshuaj xyuas Hlau pas nrig ua cov khoom siv hauv paus

SLA (Stereolithography)

Cov txheej txheem dav dav rau qhov zoo ntawm qhov chaw thiab qib ntau lawm

SLS (Kev Xaiv Laser Sintering)

Xav ua haujlwm validation xaiv nrog tsawg lossis nruab nrab ntim xav tau

PolyJet

Xav tau kev xaiv rau kev pom thiab kev ua haujlwm pov thawj qauv

3D Printing txheej txheem sib piv

| Lub Npe | Fused Deposition Modeling | Stereolithography | Selective Laser Sintering |

| Cov ntawv luv | FDM | SLA | SLS |

| Hom khoom | Khoom (Filaments) | Liquid (Photopolymer) | Hmoov (Polymer) |

| Khoom siv | Thermoplastics xws li ABS, Polycarbonate, thiab Polyphenylsulfone; Elastomers | Thermoplastics (Elastomers) | Thermoplastics xws li Nylon, Polyamide, thiab Polystyrene; Elastomers; Composites |

| Max qhov loj me (hauv.) | 36.00 x 24.00 x 36.00 Nws | 59.00 x 29.50 x 19.70 Nws | 22.00 x 22.00 x 30.00 Nws |

| Min feature loj (hauv.) | 0.005 ib | 0.004 ib | 0.005 ib |

| Min txheej thickness (hauv.) | 0.0050 Nws | 0.0010 Nws | 0.0040 Nws |

| Tolerance (hauv.) | ± 0.0050 | ± 0.0050 | ± 0.0100 |

| Nto tiav | Rough | du | Nruab nrab |

| Tsim kom ceev | qeeb | Nruab nrab | Ceev ceev |

| Daim ntawv thov | Tsawg-qis ceev prototyping Basic pov thawj-ntawm-cov tswv yim qauv Xaiv qhov kawg-siv nrog high-end muaj tshuab thiab cov ntaub ntawv | Daim ntawv / haum kuaj, Kev sim ua haujlwm, cov qauv siv nrawm nrawm, Snap fits, Cov ncauj lus kom ntxaws heev, nthuav qhia qauv, kev siv kub kub | Kev xeem daim ntawv / haum, Kev sim ua haujlwm, cov qauv siv ceev ceev, Cov ncauj lus kom ntxaws tsawg dua, Cov khoom siv nrog snap-fits & nyob hinges, Kev siv kub kub |

3D Printing Khoom

ABS

Cov khoom siv ABS yog cov yas zoo heev uas muaj lub zog muaj zog rau cov qauv qauv siv tau zoo nyob rau theem ua ntej. Nws tuaj yeem ua tau yooj yim polished rau glossy nto tiav

Xim: Dub, Dawb, Pob tshab

Qhov zoo tshaj plaws rau:

- Nrhiav kom tsim tawv, rugged lossis polishable prints nrog glossy tiav

- Cov kws tshaj lij tab tom nrhiav rau tus nqi qis tab sis muaj lub zog loj prototypes

PLA

PLA luam tawm ntawm qhov kub thiab txias, thiab ua raws li lub txaj luam tawm. Vim tias cov khoom siv no kuj pheej yig, koj tuaj yeem raug nqi zoo 3D luam tawm ntau qhov kev hloov pauv ntawm qhov pib tsim qauv.

Xim: nruab nrab, dawb, dub, xiav, liab, txiv kab ntxwv, ntsuab, liab dawb, aqua

Zoo tshaj rau

- Leej twg tab tom nrhiav 3D luam tawm yam tsis muaj kev ntxhov siab

- Leej twg tsis txhawj txog qhov kub thiab txias los yog cuam tshuam qhov chaw

- Cov kws tshaj lij tab tom nrhiav tus qauv pheej yig thiab ua tau zoo

PETG

PETG yog qhov chaw nruab nrab ntawm ABS thiab PLA. Nws muaj zog dua PLA, thiab warps tsawg dua ABS, nrog rau muab qee qhov zoo tshaj plaws txheej adhesion ntawm 3D luam ntawv filament

Xim: Dub, Dawb, Pob tshab

Qhov zoo tshaj plaws rau:

- Leej twg txaus siab rau PETG glossy nto tiav

- Ib tug neeg tab tom nrhiav kom tau txais txiaj ntsig ntawm PETG cov zaub mov zoo thiab dej tsis zoo

TPU / Silicone

TPU tsis zoo li lwm cov filaments feem ntau siv vim nws hloov tau yooj yim - thiab siv los hloov roj hmab (uas tsis tuaj yeem luam 3D) thaum xav tau kev hloov pauv. Nws yog feem ntau siv hauv xov tooj thiab npog tiv thaiv. Lub hardness tuaj yeem nyob hauv 30 ~ 80shore A

Xim: Dub, Dawb, Pob tshab

Qhov zoo tshaj plaws rau:

- Nrhiav kom tsim tau txias 3D luam tawm qhov chaw xws li xov tooj, npog, thiab lwm yam

- Nrhiav qhov muag muag rau tawv 3D luam tawm qhov chaw

Nylon

Nylon yog cov khoom siv hluavtaws 3D luam tawm cov khoom siv polymer uas muaj zog, ruaj khov, thiab hloov tau yooj yim thiab feem ntau siv rau qhov kawg siv thiab kuaj ntawm qhov siab. Nylon 3D luam ntawv cov ntaub ntawv feem ntau yog siv los tsim cov qauv muaj zog uas tuaj yeem kuaj tau hauv kev lag luam, nrog rau kev tsim cov khoom xws li iav, pob khawm, ntsia hlau, thiab cov khoom zoo sib xws.

Xim: SLS: Dawb, Dub, Ntsuab MJF: Grey, Dub

Qhov zoo tshaj plaws rau:

- High-kev ua tau zoo prototypes rau kev lag luam

- Qhov zoo tshaj plaws kev ua tau zoo xws li cov ntsia hlau, iav thiab hinges

- Qhov cuam tshuam-tiv taus qhov twg qee qhov yooj yim dua

Aluminium / Stainless hlau

Aluminium yog lub teeb yuag, ruaj, muaj zog, thiab muaj cov thermal zoo.

Stainless hlau muaj lub zog siab, siab ductility, thiab tiv taus corrosion.

Xim: Ntuj

Qhov zoo tshaj plaws rau: Lub zog muaj zog prototypes xeem validation

ABS

TPU

PLA

Nylon

Los ntawm Tswv Yim rau Kev Muaj Peev Xwm

Ceev thiab yoog raws Prototypes

Quick 3D luam ntawv qhov chaw xa sai li 12 teev.

Hla cov kev txwv ntawm lub complex geometry

Kev xaiv luam ntawv: FDM

Khoom siv: PLA, ABS

Lub sij hawm tsim khoom: sai li 1 hnub

High Quality Functional Validation

Tau txais cov qauv zoo tshaj plaws rau kev kuaj xyuas kom haum. Lub zog muaj zog nrog du nto

Kev xaiv luam ntawv: SLA, SLS

Khoom siv: ABS zoo li, Nylon 12, Roj hmab zoo li

Lub sij hawm tsim khoom: 1-3 hnub

Lower Order Fast Delivery

Qhov kev xaiv zoo tshaj plaws ntawm 3D luam ntawv ib qho kev thov qis dua uas yog ib txoj hauv kev pheej yig dua piv rau cov nqi siv

Kev xaiv luam ntawv: HP® Multi Jet Fusion (MJF)

Khoom siv: PA 12, PA 11

Lub sij hawm tsim khoom: sai li 3-4 hnub

Nto Finishing

Painting yog ib qho kev xaiv siv rau 3D luam tawm qhov chaw los tso saib cov xim pleev xim. Tsis tas li ntawd, kev pleev xim tuaj yeem muaj kev tiv thaiv ntawm qhov chaw.

Khoom siv:

ABS, Nylon, Aluminium, Stainless Hlau, Hlau

Xim:

Dub, ib qho RAL code lossis Pantone tus lej.

Kev ntxhib los mos:

Gloss, semi-gloss, tiaj tus, nws yog xim hlau, textured

Daim ntawv thov:

Cov khoom siv hauv tsev, tsheb qhov chaw, aluminium extrusion

Hmoov txheej yog ib hom txheej uas yog siv rau ntawm 3D luam tawm nrog cov hmoov qhuav. Tsis zoo li cov xim pleev xim ua kua uas xa los ntawm cov kuab tshuaj evaporating, hmoov txheej feem ntau yog siv electrostatically thiab tom qab ntawd kho hauv qab cua sov.

Khoom siv:

ABS, Aluminium, Stainless Hlau, Hlau

Xim:

Dub, ib qho RAL code lossis Pantone tus lej.

Kev ntxhib los mos:

Gloss los yog semi-gloss

Daim ntawv thov:

Cov khoom siv tsheb, khoom siv hauv tsev, aluminium extrusion

Polishing yog tus txheej txheem ntawm kev tsim ib tug du thiab ci ntsa iab nto, cov txheej txheem ua ib tug nto nrog lub ntsiab specular xav, tab sis nyob rau hauv ib co ntaub ntawv muaj peev xwm txo tau diffuse reflection.

Khoom siv:

ABS, Nylon, Aluminium, Brass, Stainless Hlau, Hlau

Xim:

N/A

Kev ntxhib los mos:

Glossy, ci iab

Hom:

Mechanical polishing, tshuaj polishing

Daim ntawv thov:

Lenses, hniav nyiaj hniav kub, sealing qhov chaw

Bead blasting ua rau lub ntsej muag du. Nws kuj yog ib txoj hauv kev zoo kom du tawm cov khoom ua ntej siv txheej. Kev xaiv zoo rau saum npoo.

Khoom siv:

ABS, Aluminium, tooj dag, Stainless hlau, hlau

Xim:

N/A

Kev ntxhib los mos:

Matte

Cov txheej txheem:

Sa1, Sa2, Sa2.5, Sa3

Daim ntawv thov:

Cov khoom kom zoo nkauj xav tau

Peb Kev cog lus zoo

Dab tsi yog 3D luam ntawv

Hais txog 3D printing

3D luam ntawv lossis kev tsim khoom ntxiv yog txheej txheem ntawm kev ua cov khoom peb sab ntawm cov ntaub ntawv digital. Cov khoom yog tsim los ntawm txheej siv ntau yam khoom sib txawv thiab txheej txheej adhesion technologies

Qhov zoo ntawm 3D luam ntawv

1. Kev txo nqi: qhov tseem ceeb ntawm 3D luam ntawv

2. Tsawg pov tseg: qhov tshwj xeeb los tsim cov khoom nrog cov khoom pov tseg tsawg heev, qhov no yog hu ua additive manufacturing, Thaum cov txheej txheem ntau dua yuav muaj pov tseg.

3. Txo lub sij hawm: nws yog qhov pom tseeb thiab muaj zog kom zoo dua rau 3D luam ntawv, vim nws yog txheej txheem ceev rau koj los ua tus qauv validation.

4. Kev txo qis: raws li koj tus qauv tsim, nws tuaj yeem ncaj qha dov mus rau hauv cov software kom ua raws li cov ntaub ntawv tsim los luam tawm ib txheej los ntawm ib txheej, yog li tsis muaj phau ntawv cuam tshuam thaum lub sijhawm luam ntawv.

5. Kev thov ntau lawm: Cov txheej txheem ib txwm siv molding lossis txiav, 3D luam ntawv tsis xav tau cov cuab yeej ntxiv tuaj yeem pab txhawb koj rau qhov kev thov qis dua.

Yuav ua li cas kom tau ib tug du tiav ntawm 3D luam ntawv?

Feem ntau, peb cia siab tias yuav muaj qhov zoo nkauj zoo nkauj nrog 3D cov qauv luam tawm los tso saib seb peb tuaj yeem thov thiab ua cov khoom zoo li cas, tab sis nws los txog qhov kev sib tw tshaj plaws thaum ua cov khoom nrog 3D luam ntawv, ces koj yuav xav tsis thoob li cas peb tuaj yeem ua tiav qhov no, ua tib zoo saib ntawm cov kauj ruam kom ua tiav ntawm koj 3D luam tawm ib feem ces koj yuav pom tias nws yooj yim dua li koj xav txog:

01: Txoj Kev Luam Ntawv Txoj Cai: Xaiv cov khoom siv raw thiab teeb tsa txoj cai ntawm koj lub tshuab luam ntawv 3D rau koj qhov xav tau, nws xav tau cov kws tshaj lij engineers ua qhov no.

02: Sanding Polishing: sanding polishing lub 3D luam ntawv qhov chaw yog qhov yooj yim tab sis xav tau kev tsom mus rau cov ntsiab lus ib kauj ruam ntawm 100-1500 grit kom ua tiav ib qho kev ua tiav tsis muaj cov kab thiab cov kev ntxhib los mos, thaum koj ua tiav qhov ntawd, qhov chaw yuav tsum du heev.

03: Nto Hluav Taws Xob corrosion: nws tuaj yeem ua tiav ntawm 3D luam ntawv hlau qhov chaw uas siv hluav taws xob xeb zoo li EDM kom ua tiav qhov zoo kawg nkaus, zoo li ci ntsa iab.