CNC Machining Service

CNC Machining muaj txheej txheem

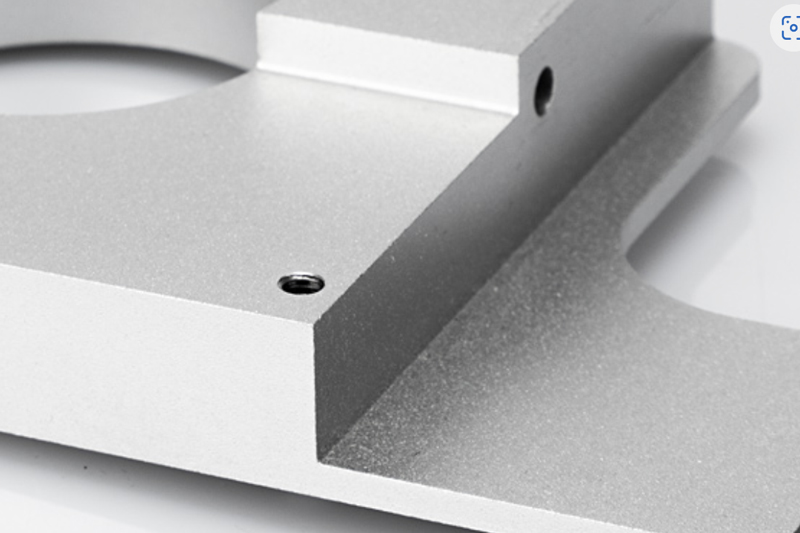

CNC Milling Service

Nrog ntau tshaj 50sets ntawm 3, 4, thiab 5-axis CNC tshuab muab qhov siab siab siab ntev mus txog ± 0.0008 "(0.02 hli) Precision CNC milling qhov chaw. Online tshuab khw rau cov qauv machining thiab ntau lawm.

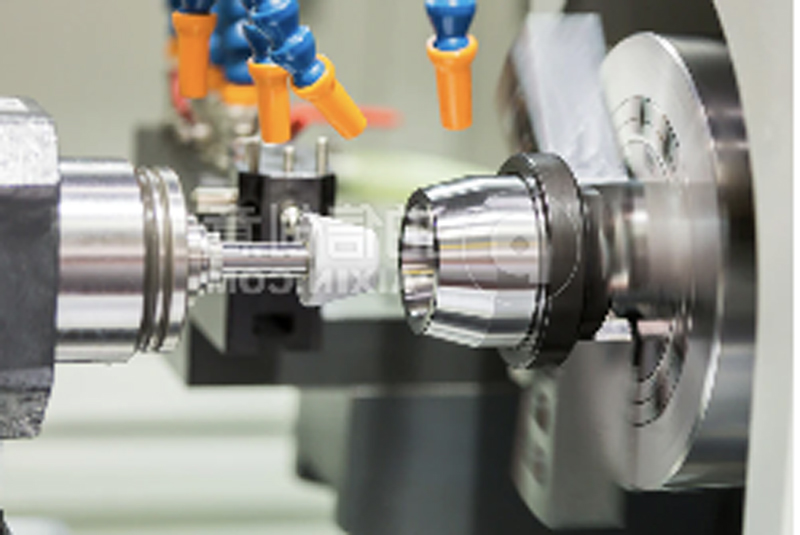

CNC tig Service

80+ CNC Lathes thiab CNC tig chaw, tuaj yeem muab cov kev pabcuam raug nqi zoo nrog cov lus teb ceev. 15+ xyoo cov kws tshaj lij engineers los txhawb nrog cov khoom lag luam nyuaj.

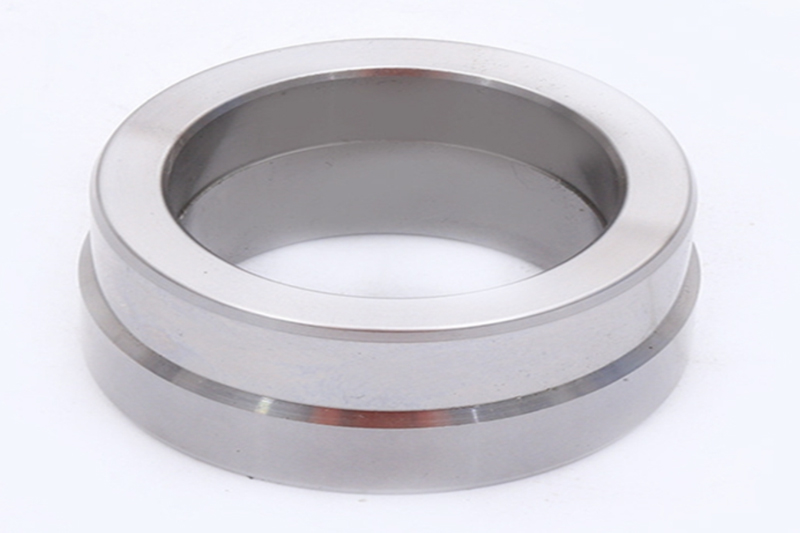

Hluav taws xob tawm Machining (EDM)

Ib txoj kev tsis sib cuag machining rau cov qauv me me. Ob hom hluav taws xob tso tawm Machining (EDM) cov txheej txheem peb muab, Hlau EDM thiab Sinker EDM. Cov txheej txheem muaj txiaj ntsig zoo rau kev txiav cov hnab ntim sib sib zog nqus thiab cov yam ntxwv nyuaj xws li lub zog thiab qhov nrog lub qhov tseem ceeb.

CNC Machining Applications

Ceev Tooling

CNC machining yog qhov kev daws teeb meem zoo tshaj plaws los tsim cov khoom siv los yog pwm. CNC machining tuaj yeem txiav ntau yam tuab tuab, cov ntaub ntawv ruaj khov xws li txhuas 5052 thiab stainless hlau.

Rapid Prototyping

Prototypes yuav tsum tau npaj nyob rau hauv 1 hnub. Peb muaj 20+ tus kws tshaj lij machinists los txhawb nqa sai thiab zoo qauv. Ntau yam ntawm cov nqi pheej yig hlau alloys thiab yas tuaj yeem siv rau cov qauv.

End-Siv Production

Tight tolerances tsawg li +/- 0.001 ", cov ntaub ntawv pov thawj cov kev xaiv thiab ntau yam txheej txheem kho saum npoo ua CNC machining ib qho cuab yeej zoo heev rau kev siv qhov kawg. Ntau txhiab daim los npaj rau hauv hnub.

CNC Machining Materials Xaiv ---- Hlau

FCE yuav pab koj nrhiav cov khoom zoo tshaj plaws raws li cov khoom xav tau thiab daim ntawv thov. Xaiv cov kev xaiv ceev thiab raug nqi los nrhiav cov khoom siv zoo tshaj plaws.

· CNC Machining Aluminium Alloys

Aluminium 6061

Aluminium 5052

Aluminium 2024

Aluminium 6063

Khoom siv: Aluminium 7050

Aluminium 7075

Aluminium MIC-6

· CNC Machining tooj liab Alloys

tooj 101

Tooj C110

· CNC Machining Bronze Alloys

tooj C932

· CNC Machining tooj dag Alloys

tooj 260

tooj 360

· CNC Machining Stainless hlau Alloys

Nitronic 60 (218 SS)

Stainless hlau 15-5

Stainless hlau 17-4

Stainless hlau 18-8

Stainless hlau 303

Stainless hlau 316/316L

Stainless hlau 416

Stainless hlau 410

Stainless hlau 420

Stainless hlau 440C

· CNC Machining Hlau Alloys

Hlau 1018

Hlau 1215

Hlau 4130

Hlau 4140

Hlau 4140PH

Hlau 4340

Hlau A36

· CNC Machining Titanium Alloys

Titanium (Qib 2)

Titanium (Qib 5)

· CNC Machining Zinc Alloys

Zinc Alloy

CNC Machining Materials Xaiv ---- Yas

FCE yuav pab koj nrhiav cov khoom zoo tshaj plaws raws li cov khoom xav tau thiab daim ntawv thov. Xaiv cov kev xaiv ceev thiab raug nqi los nrhiav cov khoom siv zoo tshaj plaws.

· ABS

ABS tau yooj yim machined los ntawm cov txheej txheem machining, xws li tig, milling, drilling thiab sawing.

· Acrylic

Lub iav zoo li yas, feem ntau yog siv rau sab nraum zoov. Zoo hnav thiab tsim kua muag.

Delrin (Acetal)

Delrin muaj cov dej noo zoo, hnav-tiv taus, thiab tsis muaj kev sib txhuam.

· Garolite G10

G10 muaj zog, machinable thiab hluav taws xob insulating. Nws yog ua los ntawm cov nplaim hluav taws-retardant epoxy resin nrog fiberglass ntaub reinforcement.

· HDPE

High-density polyethylene yog ib qho dej noo thiab tshuaj-resistant yas nrog zoo cuam tshuam lub zog. Feem ntau siv rau kev siv sab nraum zoov, cov thawv ntim dej thiab cov ntsaws ruaj ruaj.

· Nylon 6/6

Nylon 6/6 nce txhua yam zog, rigidity, zoo stability nyob rau hauv muaj kub thiab / los yog tshuaj tiv thaiv.

· PC (Polycarbonate)

PC muaj superior mechanical thiab structural zog. Siv dav hauv tsheb, aerospace, thiab lwm yam kev siv uas yuav tsum tau ua kom muaj zog thiab ruaj khov.

· PEB

PEEK feem ntau yog siv los ua lwm yam khoom siv rau cov khoom siv hlau. Feem ntau siv nyob rau hauv high-temperature, high-stress applications. PEEK tiv taus tshuaj, hnav, thiab ya raws, muab lub zog tensile zoo,

· Polypropylene

Polypropylene yog tshuaj los yog corrosion kuj. Nws muaj cov khoom siv hluav taws xob zoo heev thiab me ntsis los yog tsis muaj dej nqus. Nws nqa lub teeb loads rau lub sijhawm ntev hauv qhov kub sib txawv.

· PTFE (Teflon)

PTFE surpasses feem ntau plastics thaum nws los txog rau tshuaj tiv thaiv thiab kev ua tau zoo nyob rau hauv huab cua kub. Nws resists feem ntau cov kuab tshuaj thiab yog ib qho zoo heev hluav taws xob insulator.

· UHMW PE

Ultra-siab molecular hnyav polyethylene. UHMW PE tsis nqus dej noo thiab nws muaj kev sib xyaw ua ke ntawm kev hnav thiab kev tiv thaiv corrosion, tshuaj lom neeg ua haujlwm siab, tsis tshua muaj kev sib txhuam, muaj zog muaj zog.

· PVC

PVC feem ntau yog siv rau hauv ib puag ncig uas muaj kua los yog xav tau hluav taws xob rwb thaiv tsev. Thiab kuj yog cov tshuaj lom neeg-resistant hluavtaws yas

CNC Machining Nto Finishes

Standard (As-Milled)

Nws yog tus ceev tshaj turnaround machining txheej txheem. Nws muaj qhov roughness ntawm 3.2 μm (126 μin). Tag nrho cov npoo ntse raug tshem tawm, thiab qhov chaw yog deburred. Cov cuab yeej cim tau pom.

Bead Blast

Qhov saum npoo yog sab laug nrog tus du, matte tsos

Tumbled

Nws yog tus ceev tshaj turnaround machining txheej txheem. Nws muaj qhov roughness ntawm 3.2 μm (126 μin). Tag nrho cov npoo ntse raug tshem tawm, thiab qhov chaw yog deburred. Cov cuab yeej cim tau pom.

Anodized

Cov khoom tuaj yeem ua anodized nyob rau hauv ntau yam xim - Ntshiab, dub, grey, liab, xiav, kub.

Passivation

Cov khoom tuaj yeem ua anodized rau ntau yam xim - dub, ntshiab, liab, thiab kub.

Hmoov Txheej

Cov khoom tuaj yeem ua anodized rau ntau yam xim - dub, ntshiab, liab, thiab kub.

CNC Machining Design Guidelines

| Feature | Kev piav qhia |

| Internal ces kaum fillets | Tsim cov kaum sab hauv los ua 0.020 "- 0.050" ntau dua li tus qauv laum loj rau lub radii. Ua raws li txoj kab uas hla mus rau qhov tob ntawm 1: 6 (1: 4 pom zoo) raws li cov lus qhia rau sab hauv kaum sab xis. |

| Pem teb fillets | Tsim cov fillets hauv pem teb me dua lub kaum sab xis kom tso cai rau tib lub cuab yeej kom tshem tawm cov khoom ntawm sab hauv. |

| Undercuts | Ib txwm tsim undercuts rau qhov ntau thiab tsawg thiab deb ntawm cov ces kaum kom lawv nkag tau los ntawm cov cuab yeej txiav. |

| Tapped/threaded qhov tob | Muab cov cuab yeej tshem tawm me ntsis dhau ntawm lub qhov tob tob kom paub meej cov xov tiav. |

| nyuaj | Khaws cov naj npawb ntawm cov txiav me me kom tsawg kom txo tau cov nqi CNC machining; tsuas yog tsim nyob rau hauv cov yam ntxwv tsim nyog kom sib npaug ua haujlwm nrog kev zoo nkauj. |

CNC Machining Tolerances

| Feature | Kev piav qhia |

| Qhov Loj tshaj plaws | Milled qhov chaw txog li 80 "x 48" x 24" (2,032 x 1,219 x 610 mm). Tshuab dhos qhov ntev txog 62 "(1,575 mm) ntev thiab 32" (813 mm) inch. |

| Standard Lead Time | 3 hnub ua haujlwm |

| Kev Tolerances | Kev kam rau siab ntawm cov hlau yuav raug tuav rau +/- 0.005 "(+/- 0.127 mm) raws li ISO 2768 tshwj tsis yog tau teev tseg. Cov yas thiab cov khoom sib xyaw yuav yog +/- 0.010". |

| Precision Tolerances | FCE tuaj yeem tsim thiab tshuaj xyuas kom nruj nruj raws li koj qhov kev kos duab tshwj xeeb suav nrog GD&T callouts. |

| Yam tsawg kawg nkaus Feature Size | 0.020 "(0.50 mm) Qhov no yuav txawv nyob ntawm seb qhov geometry thiab cov khoom xaiv. |

| Xov thiab Tapping Qhov | FCE tuaj yeem ua raws li tus qauv xov loj. Peb kuj tuaj yeem ua cov tshuab kev cai xov; cov no yuav xav tau kev tshuaj xyuas phau ntawv sau tseg. |

| Ntug mob | Cov npoo ntse yog tawg thiab deburred los ntawm lub neej ntawd |

| Nto tiav | Cov txheej txheem tiav yog raws li-machined: 125 Ra lossis zoo dua. Cov kev xaiv ua tiav ntxiv tuaj yeem teev tau thaum tau txais cov lus tsocai. |

Peb Kev cog lus zoo