Hauv Mould Labeling

CNC Machining muaj txheej txheem

Engineering Expertise thiab Kev taw qhia

Pab neeg ua haujlwm engineering yuav pab koj ntawm kev txhim kho molding qhov tsim, GD&T kos, xaiv cov khoom siv. 100% xyuas kom meej cov khoom nrog siab ntau lawm feasibility, zoo, traceability

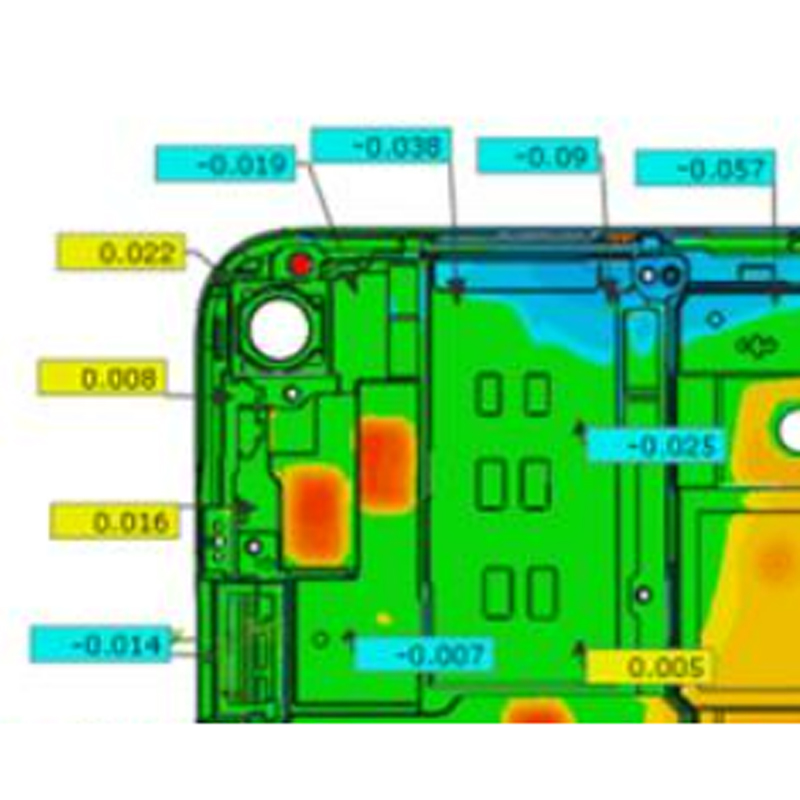

Simulation ua ntej Txiav Hlau

Rau txhua qhov projection, peb yuav siv pwm-ntws, Creo, Mastercam los simulate cov txheej txheem txhaj tshuaj molding, txheej txheem machining, txheej txheem kos duab los kwv yees qhov teeb meem ua ntej ua cov qauv ntawm lub cev.

Cov khoom tsim tsim tau yooj yim txais

Peb muaj cov khoom lag luam zoo tshaj plaws hauv kev txhaj tshuaj molding, CNC machining thiab sheet hlau fabrication. Uas tso cai complex, siab precision yuav tsum tau cov khoom tsim

Hauv tsev txheej txheem

Kev txhaj tshuaj pwm ua, Txhaj tshuaj molding thiab txheej txheem thib ob ntawm cov ntaub ntawv luam tawm, kev kub hnyiab, kub stamping, sib dhos yog tag nrho hauv tsev, yog li koj yuav muaj tus nqi qis thiab txhim khu kev txhim kho lub sijhawm.

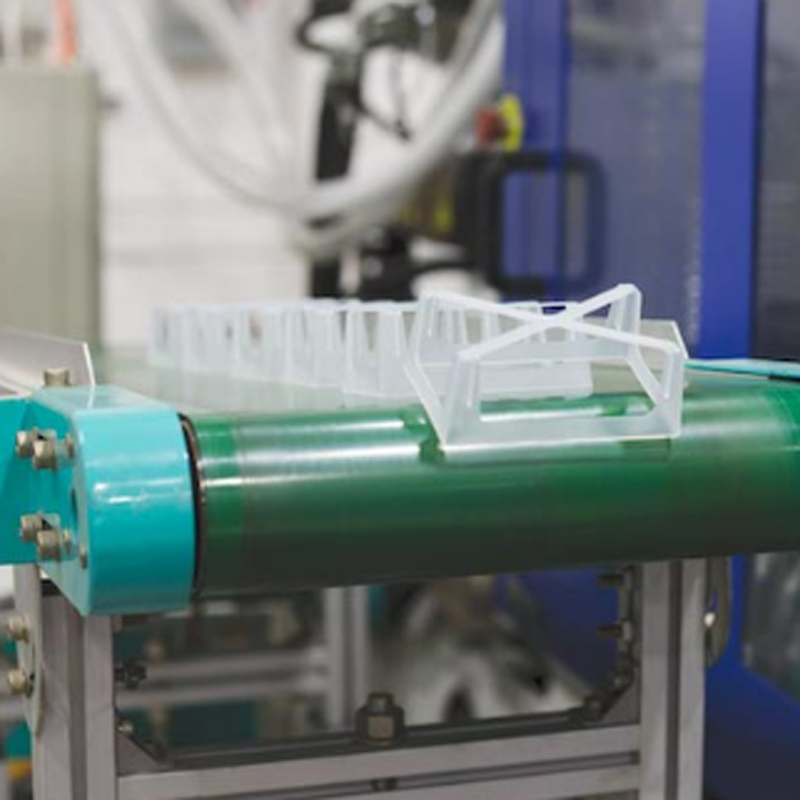

Hauv Mould Labeling

Hauv Mould Labeling (IML) yog txheej txheem kev txhaj tshuaj molding uas yog kev kho kom zoo nkauj ntawm cov yas, siv daim ntawv lo, yog tsim thaum lub sijhawm txhaj tshuaj yas. Cias muab tso, ib daim ntawv preprinted yog muab tso rau ntawm automation rau hauv kab noj hniav ntawm ib tug txhaj pwm thiab yas yog txhaj rau ntawm daim ntawv lo. Qhov no ua rau cov khoom dai kom zoo nkauj / "labeled" yas nyob rau hauv uas daim ntawv lo yog fused mus tas li rau qhov nws tus kheej

Qhov zoo ntawm Rosti hauv-mould labeling cov txheej txheem suav nrog:

• Txog li 45% foil curvature (qhov tob rau qhov dav)

• Cov txheej txheem qhuav thiab hnyav hnyav

• Muaj peev xwm tsim tsis txwv

• Kev hloov pauv sai sai

• Cov duab daws teeb meem siab

• Tus nqi qis, tshwj xeeb tshaj yog rau cov haujlwm loj

• Ua tiav cov teebmeem tsis ua tau nrog lwm cov thev naus laus zis

• Muaj zog thiab ruaj khov rau kev tu cev ntawm cov khoom khov thiab cov fridge

• Kev puas tsuaj-resistant tag

• Kev paub txog ib puag ncig

Qhov zoo ntawm IML

Qee qhov txiaj ntsig zoo ntawm IML suav nrog:

• Ua tiav kev kho kom zoo nkauj ntawm qhov molded

• Durability ntawm cov duab: Inks yog tiv thaiv los ntawm zaj duab xis nyob rau hauv lub thib ob nto tsim

• Cov haujlwm thib ob cuam tshuam nrog kev kho kom zoo nkauj tom qab molding raug tshem tawm

• Kev tshem tawm qhov xav tau rau thaj chaw daim ntawv lo

• Ntau cov yeeb yaj kiab thiab kev tsim kho muaj kom tau raws li cov neeg siv khoom xav tau

• Yooj yim los tsim cov ntawv siv ntau xim

• Feem ntau txo cov nqi seem

• Ntau ruaj thiab tamper-proof

• Cov xim sib npaug zoo dua

• Tsis muaj thaj chaw uas av tuaj yeem sau tau

• Muaj xim tsis txwv

Hauv Mould Labeling Application

Nws yog ntau npaum li cas ntawm koj tus kheej lub tswv yim los txiav txim siab seb cov haujlwm twg tuaj yeem siv rau hauv-pwm labelling, tab sis ntawm no yog qee qhov txuas mus ntxiv thiab tuaj;

- qhuav tumbler lim, kom automate nyob rau hauv cov txheej txheem pub

- kos npe ntawm syringes thiab vials

- coding thiab marking Cheebtsam rau kev lag luam automotive

- personalization ntawm cov khoom rau kev lag luam kws tshuaj thiab lwm yam

- traceability ntawm cov khoom nrog RFID

- Kho kom zoo nkauj nrog cov ntaub ntawv tsis zoo xws li textiles

Daim ntawv teev npe tuaj yeem ua tau ntev dua thiab yav tom ntej yuav qhia tshiab tseem tsis tau hnov txog cov ntawv thov uas yuav ua rau kev tsim khoom pheej yig dua thiab sai dua, txhim kho qhov zoo thiab txhim kho kev nyab xeeb, traceability thiab kev faib tawm.

Hauv Mould Labeling Material

Adhesion ntawm txawv foils thiab overmoulding cov ntaub ntawv

| Cov khoom siv overmolded | |||||||||||||||||

| ABS | ASA | EVA | PA 6 | PAB 66 | PBT | PC | PEHD | PELD | PET | PMMA | POM | PP | PS-HI | SAN | TPU | ||

| Cov ntaub ntawv foil | ABS | ++ | + | + | + | + | — | — | + | + | — | — | ∗ | + | + | ||

| ASA | + | ++ | + | + | + | — | — | + | + | — | — | — | + | + | |||

| EVA | + | + | ++ | + | + | + | + | + | |||||||||

| PA 6 | ++ | + | ∗ | ∗ | ∗ | ∗ | — | ∗ | — | + | + | ||||||

| PAB 66 | + | ++ | ∗ | ∗ | ∗ | ∗ | — | — | — | + | + | ||||||

| PBT | + | + | ∗ | ∗ | ++ | + | — | — | + | — | — | — | — | + | + | ||

| PC | + | + | ∗ | ∗ | + | ++ | — | — | + | + | — | — | — | + | + | ||

| PEHD | — | — | + | ∗ | ∗ | — | — | ++ | + | — | ∗ | ∗ | — | — | — | — | |

| PELD | — | — | + | ∗ | ∗ | — | — | + | ++ | — | ∗ | ∗ | + | — | — | — | |

| PET | + | + | + | + | — | — | + | — | — | — | + | ||||||

| PMMA | + | + | — | — | ∗ | ∗ | — | ++ | ∗ | — | + | ||||||

| POM | — | — | — | — | — | — | ∗ | ∗ | — | ++ | — | — | — | ||||

| PP | — | — | + | ∗ | — | — | — | — | + | ∗ | — | ++ | — | — | — | ||

| PS-HI | ∗ | — | + | — | — | — | — | — | — | — | — | — | — | ++ | — | — | |

| SAN | + | + | + | + | + | + | + | — | — | + | — | — | — | ++ | + | ||

| TPU | + | + | + | + | + | + | — | — | + | — | — | + | + | ||||

++ Zoo adhesion, + Zoo adhesion, ∗ Tsis muaj adhesion, - Tsis muaj adhesion.

EVA, Ethylene vinyl acetate; PA6, Polyamide 6; PA66, Polyamide 66; PBT, Polybutylene terephthalate; PEHD, Polyethylene siab ceev; PELD, Polyethylene tsawg ntom; POM, Polyoxymethylene; PS-HI, Polystyrene siab cuam tshuam; SAN, Styrene Acrylonitrile; TPU, Thermoplastic polyurethane.

Cov txheeb ze muaj zog ntawm IML vs. IMD labeling solutions

Ua ke cov txheej txheem kho kom zoo nkauj nrog cov txheej txheem molding ntxiv cov kav ntev, txo cov nqi tsim khoom thiab tsim kev tsim qauv yooj yim.

Durability

Cov duab kos tsis tuaj yeem tshem tawm yam tsis tau rhuav tshem cov yas thiab yuav nyob twj ywm rau lub neej ntawm qhov. Cov kev xaiv muaj rau kev txhim kho durability nyob rau hauv hnyav ib puag ncig thiab tshuaj tiv thaiv.

Nqi-zoo

IML tshem tawm cov ntawv sau tom qab molding, tuav thiab khaws cia. Nws txo WIP cov khoom muag thiab lub sijhawm ntxiv uas xav tau rau kev kho kom zoo nkauj tom qab tsim khoom, nyob rau hauv lossis tawm ntawm qhov chaw.

Tsim yooj

IML muaj nyob rau hauv ntau yam xim, teebmeem, textures thiab nraaj xaiv thiab tuaj yeem rov ua dua txawm tias qhov nyuaj tshaj plaws xws li stainless hlau, ntoo nplej thiab carbon fiber. Thaum yuav tsum tau daim ntawv pov thawj UL, cov qauv ntawm cov pwm pwm raug soj ntsuam raws li cov qauv kev nyab xeeb uas siv los ntsuas cov ntawv siab-rhiab heev.