Hot sale Factory Medical Plastic Injection - CE Certifacition FCE Aerospace Product – FCE Detail:

New Product Development for Aerospace Products

EV

EVT

DV

DVT

PV

PVT

Production

PrototypingRapid turn-around times for early stage designs with a wide range of 3D printing and Machining.Accurate Models to Finalize Product DesignRapid Prototypes To Keep up with Frequent Design optimization

Basic Function check Before investing in Tooling

Engineering Validation Stage

Iterate quickly on high-resolution, functional prototypes with rapid Injection Molding

High Resolution Functional Prototypes To Compare Configurations

High Quality Design Options For Design Of Experiments

Optimize Material Properties For Your Design

Design Validation Stage

Validate part strength, function, and aesthetic finish with production injection molding, also the parts are high quality parts for reliability and Life test.

High Quality Parts for Reliability and Life-Cycle Testing

Validate Appearance and Durability of Surface Finish

Process Capability Design for Mass Production

Production Validation Stage

Prepare your designs for scale with transparent documentation to improve production processes and advanced quality control services.

Run fixtures to verify production part functionality and yield.

Tight tolerances for precision parts during production.

Fully functional PPAP parts for customer approval.

Production Stage

Transition seamlessly to production and incorporate your precise quality requirements into the FCE Manufacturing System.

All process parameters are determined and documented.

All yields on production parts are within requirements.

All Capacity meet the requirement.

Faster Develop Time

FCE ensure your aerospace products from concept to achievable products. FCE engineers can reduce develop time by as much as 50%

10x Tighter Tolerances

FCE can machine parts with tolerances as tight as +/- 0.001 in — 10x greater precision compared to other leading services.

Seamless Transition to Production

FCE is an approved production parts supplier for leading aerospace enterprises, verified to be compliant with ISO 9001.

Ready to Build?

Questions?

Resources for Aerospace Product Engineers

The seven components of injection mold, do you know?

Mechanisms, ejector and core-pulling mechanisms, cooling and heating systems, and exhaust systems are categorized by function. The analysis of the seven sections is as follows:

Mold customization

FCE is a company specializing in the manufacture of high-precision injection molds, engaged in the manufacture of medical, two-color molds, and ultra-thin box in-mold labeling. As well as the development and manufacture of household appliances, auto parts, and daily necessities molds.

Mold development

In the manufacturing process of various modern products, the existence of processing tools such as molds can bring more convenience to the entire production process and improve the quality of the produced products.

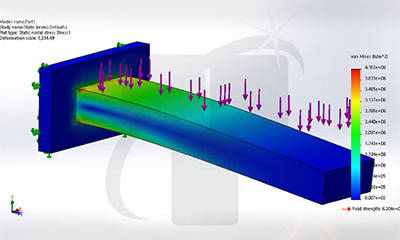

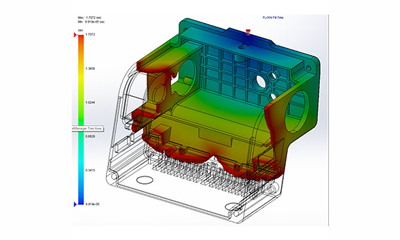

Full simulation for Aerospace Products

In FCE, We deliver a one station end-to-end service, with the resources to handle large-scale projects, combined with flexibility and attention to details.

Design Optimization

Engineering team will optimize your parts design, tolerance check, material selection. We ensure the product production feasibility and quality.

Simulation to Prevent Issues

We use mold-flow and FAE to simulate the mold structure and injection molding process to predict the potential issues.

Detailed DFM for Customer

Before Cutting still, we provide full DFM report including surface, gate, parting line, ejector pin, draft angel… to customer approval.

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Hot sale Factory Medical Plastic Injection - CE Certifacition FCE Aerospace Product – FCE , The product will supply to all over the world, such as: Panama, Roman, Azerbaijan, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.