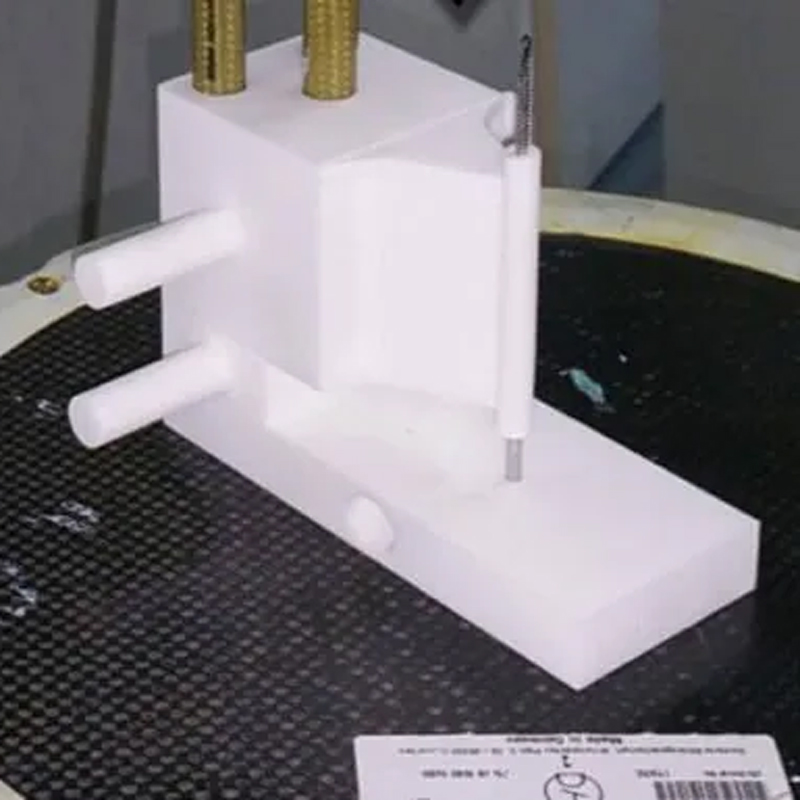

SLA

Pandhuan Desain SLA

Resolusi cetak

Ketebalan lapisan standar: 100 µm Akurasi: ± 0,2% (kanthi watesan ngisor ± 0,2 mm)

Watesan ukuran 144 x 144 x 174 mm Ketebalan minimal Ketebalan tembok minimal 0,8mm – Kanthi rasio 1:6

Etching lan Embossing

Rincian dhuwur lan jembar minimal Embossed: 0,5 mm

Ketebalan: 0,5 mm

Volume tertutup & interlocking

Bagean sing ditutupi? Ora dianjurake bagean Interlocking? Ora dianjurake

Watesan Déwan Piece

Majelis? Ora

Keahlian lan Bimbingan Teknik

Tim teknik bakal mbantu sampeyan ngoptimalake desain bagean cetakan, mriksa GD&T, pilihan materi. 100% mesthekake produk kanthi kelayakan produksi dhuwur, kualitas, traceability

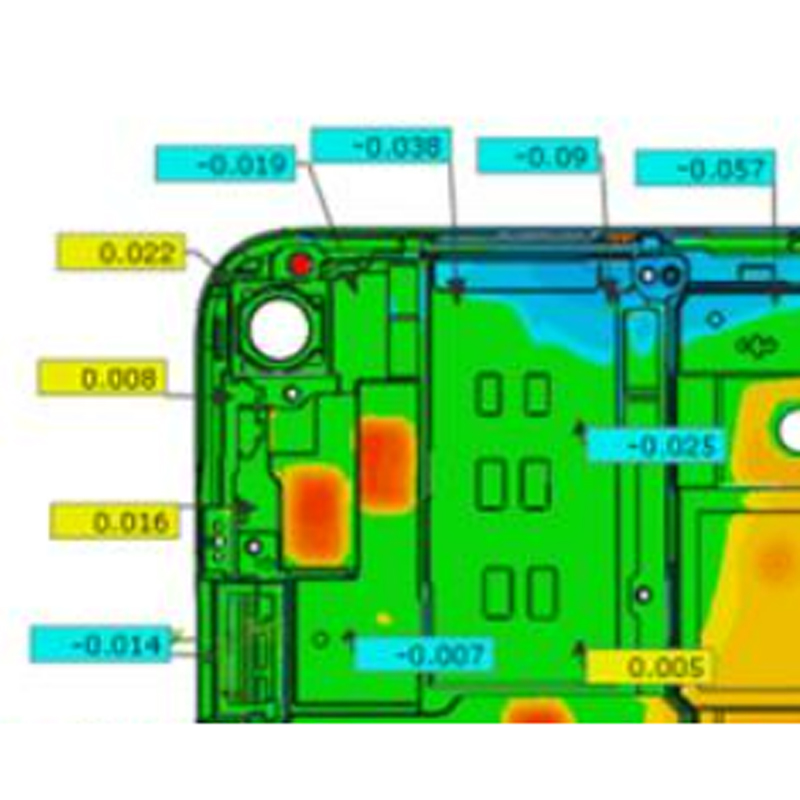

Simulasi sadurunge Cutting Steel

Kanggo saben proyeksi, kita bakal nggunakake cetakan-aliran, Creo, Mastercam kanggo simulasi proses ngecor injeksi, proses mesin, proses drawing kanggo prédhiksi masalah sadurunge nggawe conto fisik.

Desain Produk Komplek

Kita duwe fasilitas manufaktur merek ndhuwur ing cetakan injeksi, mesin CNC lan pabrikan lembaran logam. Sing ngidini desain produk sing rumit lan presisi dhuwur

Proses ing omah

Nggawe cetakan injeksi, ngecor injeksi lan proses kaping pindho pad printing, staking panas, stamping panas, perakitan kabeh ana ing omah, dadi sampeyan bakal duwe biaya sing murah lan wektu pangembangan sing dipercaya.

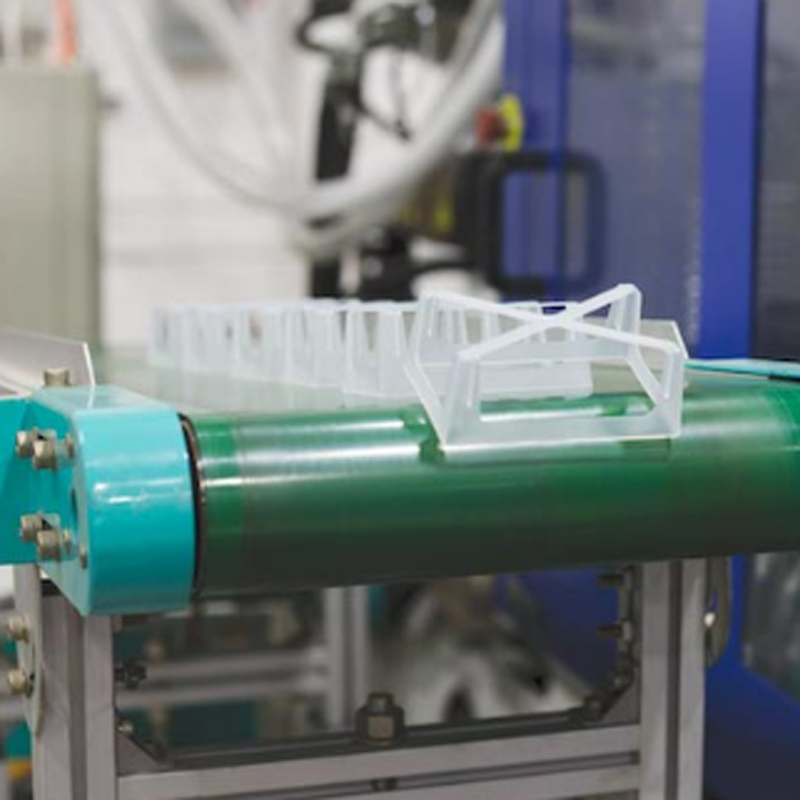

Keuntungan saka Printing SLA

Rincian tingkat dhuwur

Yen sampeyan butuh akurasi, SLA minangka proses manufaktur aditif sing dibutuhake kanggo nggawe prototipe sing rinci

Macem-macem aplikasi

Saka otomotif nganti produk konsumen, akeh perusahaan nggunakake Stereolithography kanggo prototyping kanthi cepet

kebebasan desain

Manufaktur sing didhukung desain ngidini sampeyan ngasilake geometri kompleks

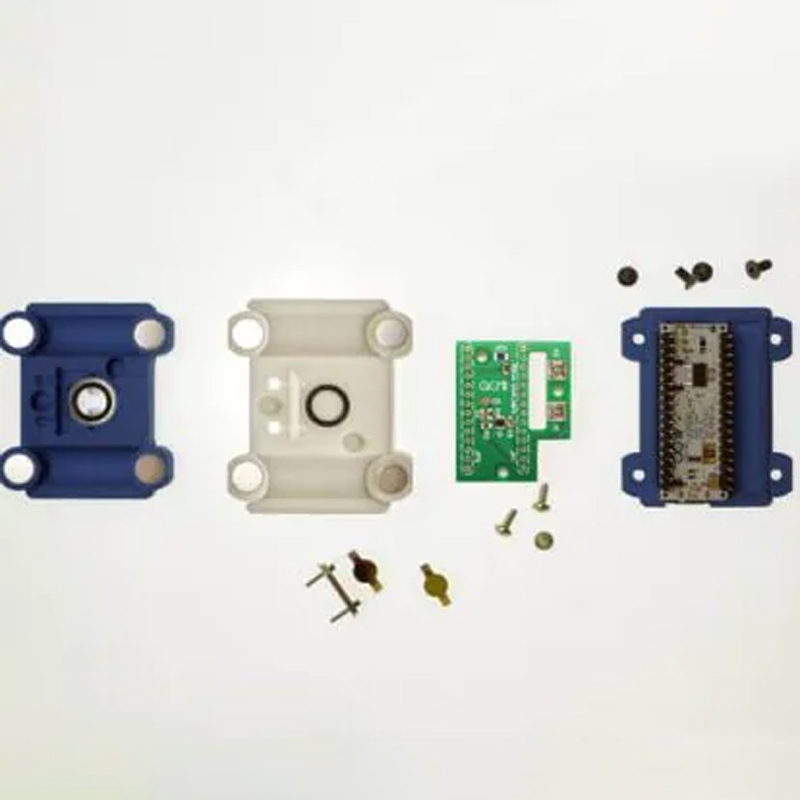

Aplikasi SLA

Otomotif

Kesehatan lan Kedokteran

Mekanik

High Tech

Barang Industri

Elektronika

SLA vs SLS vs FDM

| Jeneng Properti | Stereolithography | Selektif Laser Sintering | Fused Deposition Modeling |

| Singkatan | SLA | SLS | FDM |

| Jinis materi | Cairan (fotopolimer) | bubuk (polimer) | Padat (Filamen) |

| Bahan | Termoplastik (Elastomer) | Thermoplastics kayata Nylon, Poliamida, lan Polystyrene; elastomer; Komposit | Thermoplastics kayata ABS, Polycarbonate, lan Polyphenylsulfone; Elastomer |

| Ukuran bagean maksimal (in.) | 59,00 x 29,50 x 19,70 | 22.00 x 22.00 x 30.00 | 36.00 x 24.00 x 36.00 |

| Ukuran fitur min (in.) | 0.004 | 0.005 | 0.005 |

| Ketebalan lapisan min (in.) | 0,0010 | 0,0040 | 0,0050 |

| Toleransi (ing.) | ± 0,0050 | ± 0,0100 | ± 0,0050 |

| Rampung lumahing | Gamelan | Rata-rata | atos |

| Mbangun kacepetan | Rata-rata | Cepet | alon-alon |

| Aplikasi | Pengujian bentuk/kecocokan, Pengujian fungsional, Pola perkakas sing cepet, Pas snap, Bagian sing rinci banget, Model presentasi, Aplikasi panas dhuwur | Pengujian bentuk/kecocokan, Pengujian fungsional, Pola perkakas sing cepet, Bagian sing kurang rinci, Bagian kanthi engsel snap-fit & urip, Aplikasi panas dhuwur | Pengujian formulir/cocok, Pengujian fungsional, Pola perkakas sing cepet, Bagian rinci cilik, Model presentasi, Aplikasi pasien lan panganan, Aplikasi panas dhuwur |

Kaluwihan SLA

Stereolithography Cepet

Stereolithography Akurat

Stereolithography Bisa Kanthi Bahan sing Beda

Kelestarian

Majelis Multi-Bagian Bisa

Tekstur Bisa