Manufactur standard Molding Metal - Custom Sheet Metal Stamping – FCE Detail:

Icons

Engineering support

To ensure product viability and quality, the engineering team will share their experience, assist with part design optimization, GD&T inspection, and material selection.

Fast Delivery

Samples can be reduced to one day delivery. More than 5000 kinds of common materials stock, more than 40 machines to support your urgent needs.

Accept Complex design

Which allow for complex, high-precision product design requirements, we have a first-class brand of laser cutting, bending, automatic welding and testing equipment.

In house 2nd process

We have powder spray in different colours and luminances, pad/screen printing and hot stamping marks, riveting and welding, and even box assembly

Sheet Metal Process

FCE sheet forming service, can complete bending, rolling, drawing, deep drawing and other forming processes in one workshop. You can get very complete products with high quality and very short lead times.

Bending

Bending is a process of metal forming in which a force is applied to another sheet of metal, causing it to bend at an Angle to form the desired shape. Bending operations deform a shaft and can perform a series of different operations to create a complex component. The bending part can be very small, such as a bracket, such as a large shell or chassis

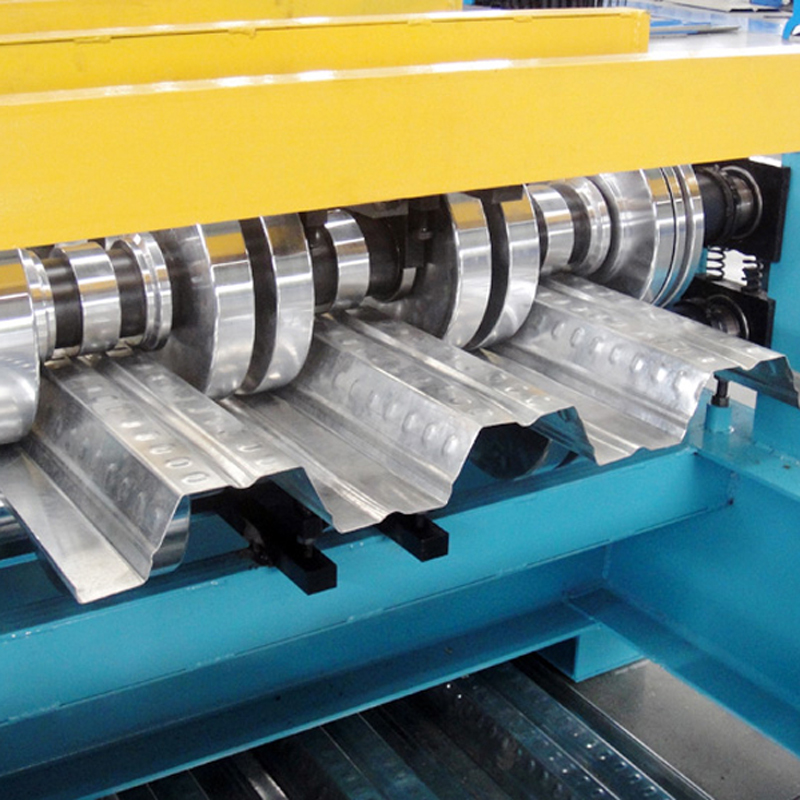

Roll forming

Roll forming, is a metal forming process in which sheet metal is progressively shaped through a series of bending operations. The process is performed on a roll forming line. Each station has a roller, referred to as a roller die, positioned on both sides of the sheet. The shape and size of the roller die may be unique to that station, or several identical roller dies may be used in different positions. The roller dies may be above and below the sheet, along the sides, at an angle, etc. the roller dies are lubricated to reduce friction between the die and the sheet, thus reducing the tool wear.

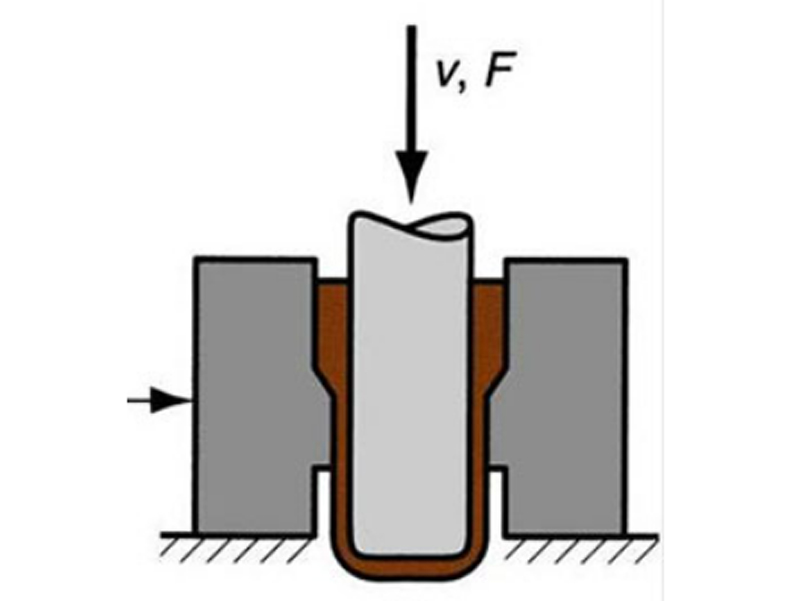

Deep drawing

Roll forming is a forming technology that gradually forms sheet metal through a series of bending process technology. The process is carried out on a rolling production line. Each station has a roller, called a roller die, on either side of the paper. The shape and size of the roll molds are unique, or several identical roll molds can be operated in different locations. The roller die can be operated above and below the sheet, along the side, at an Angle, etc. The roller die is lubricated to reduce friction between the die and the sheet, reducing tool wear.

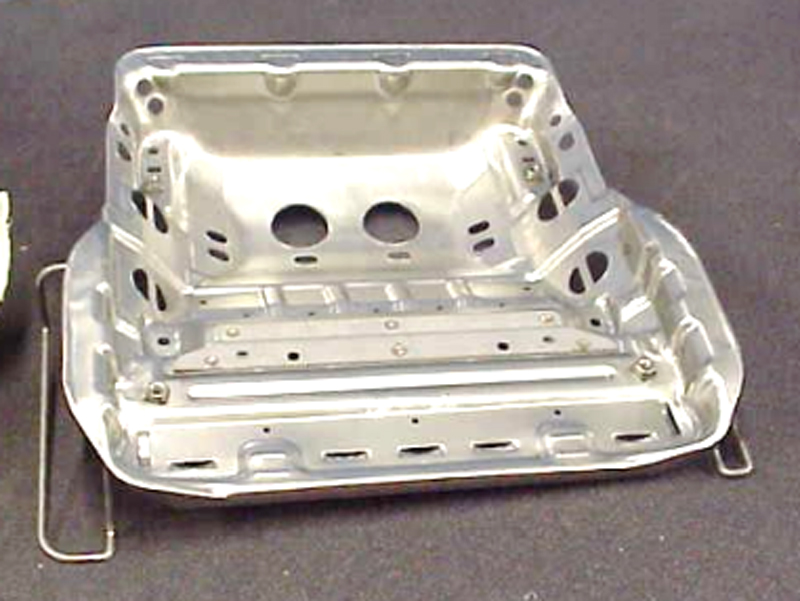

Drawing for Complex Shapes

FCE also has experience in sheet metal fabrication of complex profiles. In addition to deep drawing, good quality parts were obtained in the first trial production by finite element analysis.

Ironing

The sheet metal is being ironed to get an even thickness. With this process, you can dilute on the side walls of the product. The thickness of the bottom. Typical applications are cans, cups, etc.

Available Materials for sheet metal fabrication

FCE prepared 1000+ common sheet material in stock for fastest turnaround, Our mechanical engineering will help you on material selection, mechanical analysis, feasibility optimizations

| Aluminum | Copper | Bronze | Steel |

| Aluminum 5052 | Copper 101 | Bronze 220 | Stainless Steel 301 |

| Aluminum 6061 | Copper 260 (Brass) | Bronze 510 | Stainless Steel 304 |

| Copper C110 | Stainless Steel 316/316L | ||

| Steel, Low Carbon |

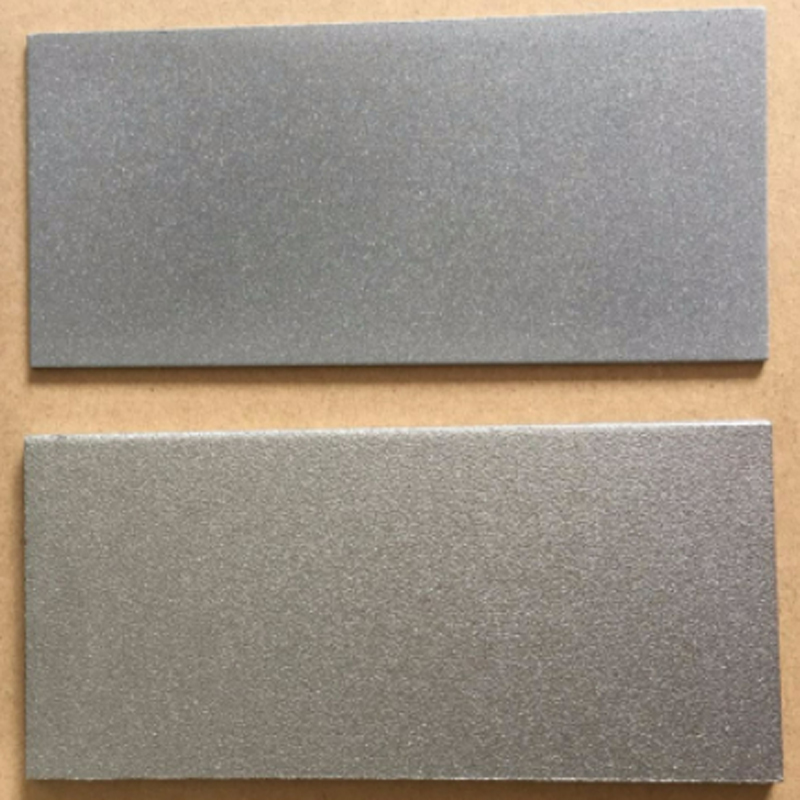

Surface Finishes

FCE offers a complete range of surface treatment processes. Electroplating, powder coating, anodizing can be customized according to color, texture and brightness. The appropriate finish can also be recommended according to functional requirements.

Brushing

Blasting

Polishing

Anodizing

Powder Coating

Hot Transfer

Plating

Printing & Laser Mark

Our Quality Promise

General FAQs

What Is Sheet Metal Fabrication?

Sheet metal processing is a subtractive manufacturing process through which parts are cut or/and formed from sheet metal. Sheet metal pieces are often used for high precision and durability requirements, with typical applications being chassis, enclosures and brackets.

What is Sheet Metal Forming?

Sheet metal forming is a process in which a force is applied to a sheet metal to change its shape rather than remove any material. The force applied to make metal than its yield strength, cause the material to plastic deformation, but will not break. After the force is released, the plate will bounce back a little, but basically keep the shape when pressed.

What is metal stamping?

In order to improve the efficiency of sheet metal fabrication, metal stamping dies are used to convert flat sheet metal into specific shapes. This is a complex process that can include many metal forming techniques -blanking, punching, bending and punching.

What is the payment term?

New clients, 30% down. Balance the rest before delivering the product. We accept a three-month settlement period for regular orders

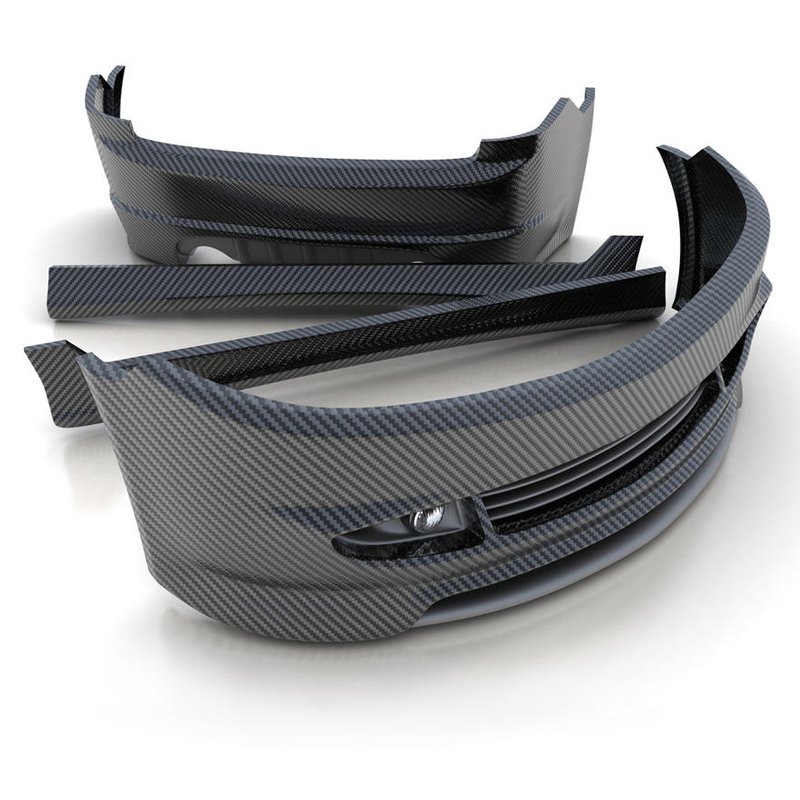

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Manufactur standard Molding Metal - Custom Sheet Metal Stamping – FCE , The product will supply to all over the world, such as: Egypt, UK, Bulgaria, We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.