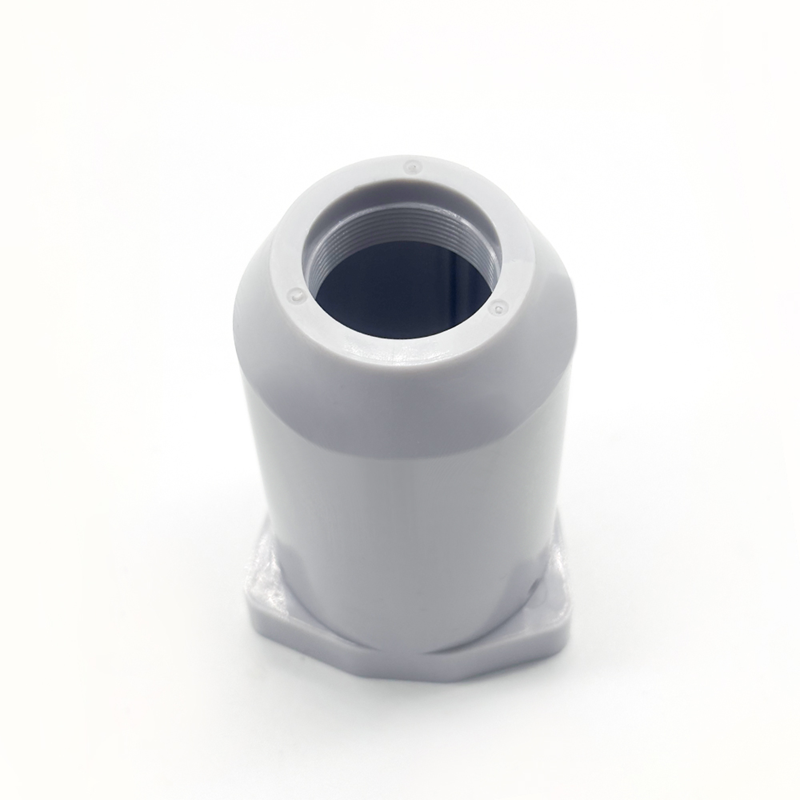

FCE partnered with Levelcon to develop the housing and base for their WP01V sensor, a product renowned for its ability to measure nearly any pressure range. This project presented a unique set of challenges, requiring innovative solutions in material selection, injection molding, and demolding to meet stringent performance and quality standards.

High-Strength, UV-Resistant Material for Extreme Pressure

The WP01V sensor housing demanded exceptional strength to endure wide-ranging pressure conditions. FCE recommended a high-strength polycarbonate (PC) material that also met UV resistance requirements, ensuring durability in outdoor environments. To optimize the housing’s performance, FCE proposed a wall thickness of 3 mm, substantiated by Finite Element Analysis (FEA). The simulation confirmed that this design could withstand extreme pressures without compromising the integrity of the material.

Innovative Internal Thread Demolding Mechanism

The housing's internal threads posed a significant challenge during the injection molding process. Without specialized measures, the threads risked becoming stuck in the mold during demolding. To address this, FCE developed a custom demolding mechanism specifically for internal threads. After thorough explanation and demonstration, the solution was approved by the client, ensuring smooth production and precise thread formation.

Structural Optimization to Prevent Shrinkage

The housing's relatively thick design risked surface shrinkage, which could affect its appearance and performance. FCE tackled this issue by incorporating ribs in critical areas with excessive thickness. This approach redistributed material and reduced shrinkage without sacrificing strength.

Additionally, to achieve superior cooling efficiency, FCE selected copper for the mold core due to its excellent thermal conductivity. The cooling system featured a specially designed water channel layout, ensuring uniform cooling and minimizing surface defects.

Successful Testing and Production Approval

Upon completing the mold, FCE provided sample parts for assembly and performance testing. The sensor housings were subjected to extreme operating conditions, performing flawlessly without any structural or functional anomalies. Levelcon approved the samples for mass production, and FCE successfully fulfilled the order with high quality and punctual delivery.

Key Takeaways

This project demonstrated FCE’s advanced expertise in:

- Pressure-resistant materials: High-strength PC materials tailored to extreme conditions.

- Custom injection molding solutions: Specialized internal thread demolding mechanisms.

- Design optimization: Rib structures and efficient cooling systems to enhance product quality.

Through innovative engineering and meticulous execution, FCE ensured the WP01V sensor housing met all client expectations, further solidifying its reputation as a leader in injection molding solutions.

Post time: Dec-04-2024