Development of Our New USA Water Bottle Design When designing our new water bottle for the USA market, we followed a structured, step-by-step approach to ensure the product meets both functional and aesthetic requirements.

Here’s an overview of the key stages in our development process:

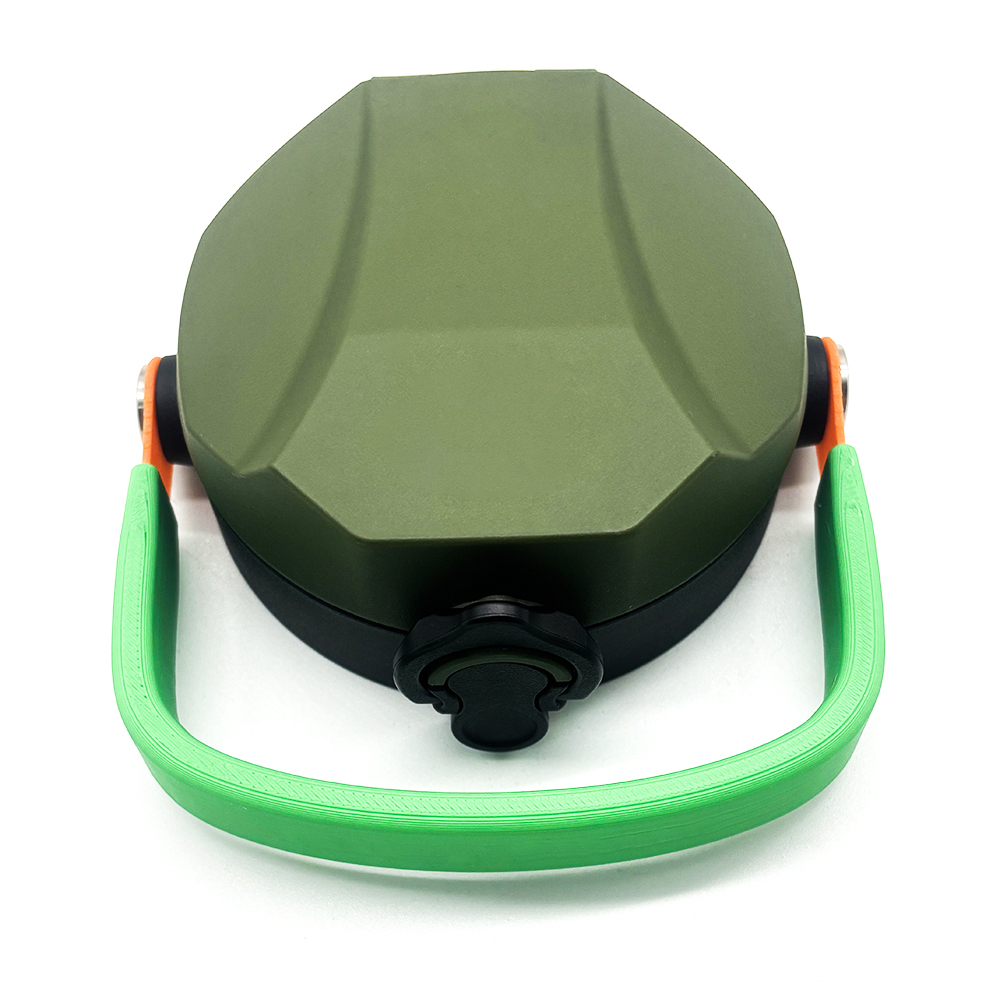

1. Overmolding Design The design features an overmolding structure where a metal part is encapsulated within polypropylene (PP) material.

2. Concept Verification To validate the initial concept, we created a sample using 3D printing with PLA material. This allowed us to evaluate the basic functionality and fit before moving to the next stage.

3. Dual-Color Integration The design incorporates two distinct colors that seamlessly blend together, highlighting both functionality and aesthetic appeal.

3D Printing Materials We use a wide range of materials in our 3D printing process, including: Engineering Plastics:PLA, ABS, PETG, Nylon, PC Elastomers: TPU Metal Materials: Aluminum, SUS304 stainless steel Specialty Materials: Photosensitive resins, ceramics 3D Printing Processes

1. FDM (Fused Deposition Modeling) Overview:A cost-effective technique ideal for creating plastic prototypes. Advantages: Quick printing speed and affordable material cost. Considerations: Surface finish is relatively rough, making it suitable for functional verification rather than cosmetic evaluation. Use Case:Ideal for early-stage testing to check part features and fit.

2. SLA (Stereolithography) Overview: A popular resin-based 3D printing process. Advantages: Produces highly accurate, isotropic, watertight prototypes with smooth surfaces and fine details. – Use Case: Preferred for detailed design reviews or aesthetic prototypes.

3. SLS (Selective Laser Sintering) Overview: A powder bed fusion technique primarily used for nylon materials. Advantages:Produces parts with strong mechanical properties, making it ideal for functional and strength-critical applications. Second-Generation Improvements For the second-generation water bottle design, we focused on cost optimization while maintaining functionality.

To achieve this:

- We used PLA with FDM technology to create samples for verification.

- PLA offers a wide range of color options, allowing us to prototype with various aesthetic possibilities.

- As shown in the image, the 3D-printed sample achieved excellent fitment, proving the feasibility of our design while keeping costs low. This iterative process ensures we develop a reliable, cost-effective, and visually appealing product before proceeding to full-scale production.

Post time: Nov-25-2024