One of Hottest for Silicone Injection Molding Companies - Best China Insert Molding manufacturer – FCE Detail:

Engineering Expertise and Guidance

Engineering team will help you on optimize molding part design, GD&T check, material selection. 100% ensure the product with high production feasibility, quality, traceability

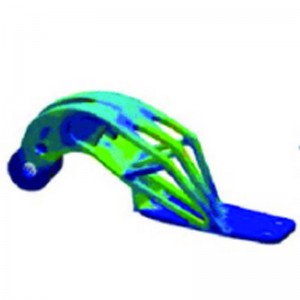

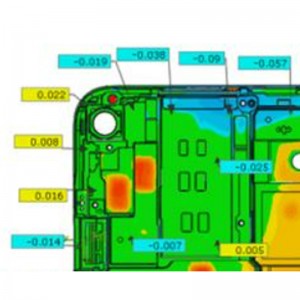

Simulation before Cutting Steel

For each projection, we will use mold-flow, Creo, Mastercam to simulate the injection molding process, machining process, drawing process to predict the issue before make physical samples

Precise Complex Product Manufacturing

We have the top brand manufacturing facilities in injection molding, CNC machining and sheet metal fabrication. Which allows complex, high precision requirement product design

In house process

Injection mold making, Injection molding and second process of pad printing, heat staking, hot stamping, assembly are all in house, so you will have much low cost and reliable development lead time

Insert Molding

Insert molding is an injection molding process that utilizes encapsulation of a component in the plastic part. The process consists of two necessary steps.

Firstly, a finished component is inserted into the mold before the molding process actually takes place. Secondly, the molten plastic material is poured into the mold; it takes part’s shape and joints with the previously added part.

Insert molding can be performed with a wide variety of inserts, materials will be such as:

- Metal fasteners

- Tubes and studs

- Bearings

- Electrical components

- Labels, decorations, and other aesthetic elements

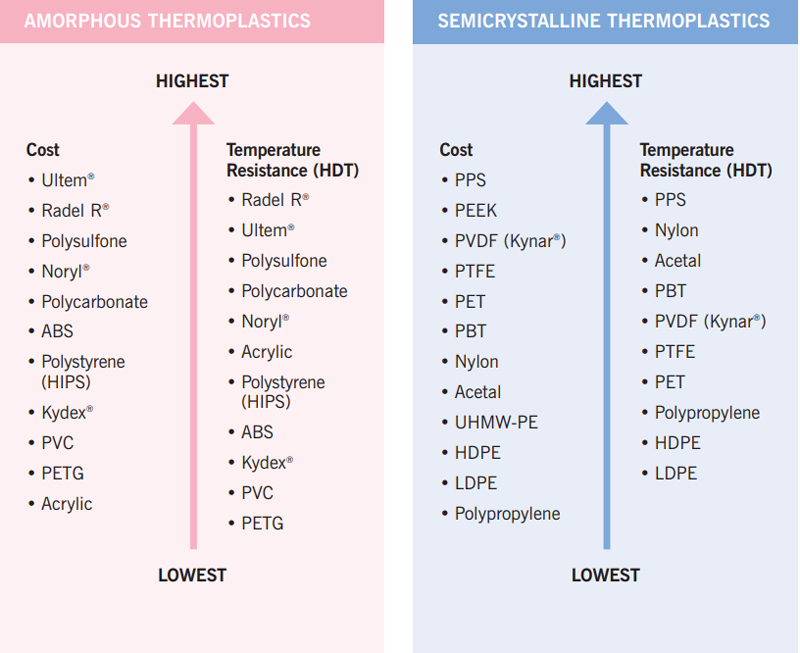

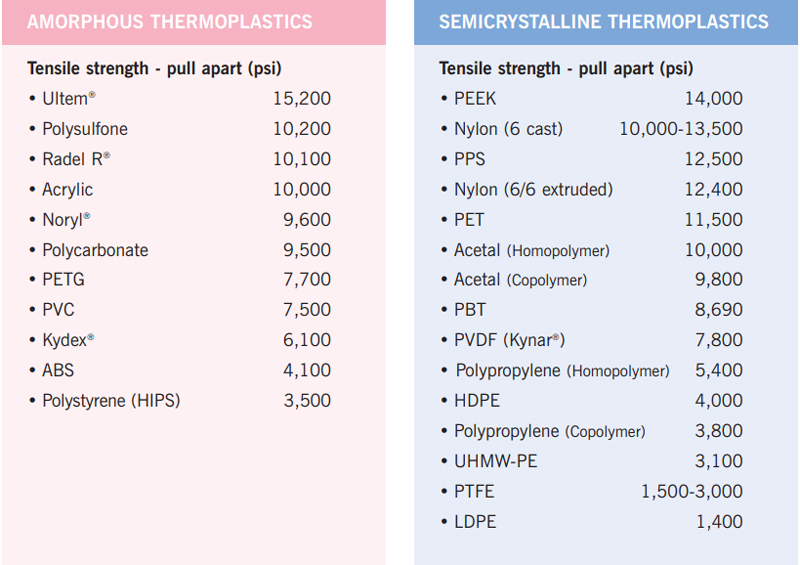

Material Selection

FCE will help you find best material according to the product requirement and application. There is a lot of choices in the market, we will also according the cost effective and supply chain stability to recommend the brand and grade of resins.

Molded part Finishes

| Glossy | Semi-Glossy | Matte | Textured |

| SPI-A0 | SPI-B1 | SPI-C1 | MT (Moldtech) |

| SPI-A1 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| SPI-A2 | SPI-B3 | SPI-C3 | YS (Yick Sang) |

| SPI-A3 |

Increases Design Flexibility

Insert molding allows designers and manufacturers to make virtually any type of shape or design that they desired

Reduces Assembly and Labor Costs

Combine several separate components into one injection molding, making more cost-effective. With insert molding being a one-step process, greatly reduce assembly steps and labor costs

Increases Reliability

Melted plastic flows freely around every insert before cooling and permanently setting, insert is firmly held in plastic

Reduces Size and Weight

Insert molding creates plastic parts that are much smaller and lighter in weight, despite being more functional and reliable than plastic parts made with other methods

Variety of Materials

Insert molding is a process that can use many different types of plastic resins, such as high performance thermoplastics

From Prototype to Production

Rapid Design Molds

Anticipated way for part design validation, low volume verification, steps for production

- No minimum quantities limited

- Lower cost design fitment checking

- Complicated design accepted

Production Tooling

Ideal for volume production parts, Tooling costs are higher than Rapid Design Molds, but allows for lower part pricing

- Up to 5M molding shots

- Multi-cavity tooling

- Automatic and monitoring

Typical Development Process

Quote with DFx

Check you requirement data and applications, provide scenarios quote with different suggestions. Simulation report with be provided in parallel

Review prototype (alternative)

Develop rapid tool (1~2wks) to mold prototype samples for design and molding process verification

Production mold development

You can kick off ramp up immediately with prototype tool. If the demand over millions, kick off production mold with multi-cavitation in parallel, which will take approx. 2~5weeks

Repeat Order

If you have focus for the demand, we can start delivery within 2days. No focus order, we can start partial shipment as few as 3days

Insert Molding FAQs

Insert molding application

- Knobs for appliances, controls and assemblies

- Encapsulated electronic devices and electrical components

- Threaded screws

- Encapsulated bushings, tubes, studs, and posted

- Medical devices and instruments

What’s The Difference Between Insert Molding & Overmolding

Insert molding is just one of the processes used to mold plastic around a non-plastic item.

In simple terms, the key difference is that the number of steps required to achieve the end result.

On the other hand, Insert molding does the same thing, but only in one step. The difference lies in the way the final product is made. Here, the insert and molten material are located into the mold to form the final combined product.

One more fundamental difference is that insert molding is not bounded by plastic, including metals with different products

Overmolding is usually utilized to produce products with great textures, shapes, and colors, predominantly made for shelf appeal. Insert molding is used to create more rigid products.

Product detail pictures:

Related Product Guide:

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for One of Hottest for Silicone Injection Molding Companies - Best China Insert Molding manufacturer – FCE , The product will supply to all over the world, such as: Gambia, Kyrgyzstan, Spain, We are increasingly expanding our international market share based on quality products, excellent service, reasonable price and timely delivery. Please contact us at any time for more information.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!