Popular Design for 3d Injection Molding - CE Certification SLA products – FCE Detail:

SLA Design guide

Printing resolution

Standard layer thickness: 100 µm Accuracy: ±0.2% (with a lower limit of ±0.2 mm)

Size limitation 144 x 144 x 174 mm Minimum thickness Minimum wall thickness 0.8mm – With a 1:6 ratio

Etching and Embossing

Minimum height and width details Embossed: 0.5 mm

Engraved: 0.5 mm

Enclosed & interlocking volume

Enclosed parts? Not recommended Interlocking parts? Not recommended

Piece assembly Restriction

Assembly? No

Engineering Expertise and Guidance

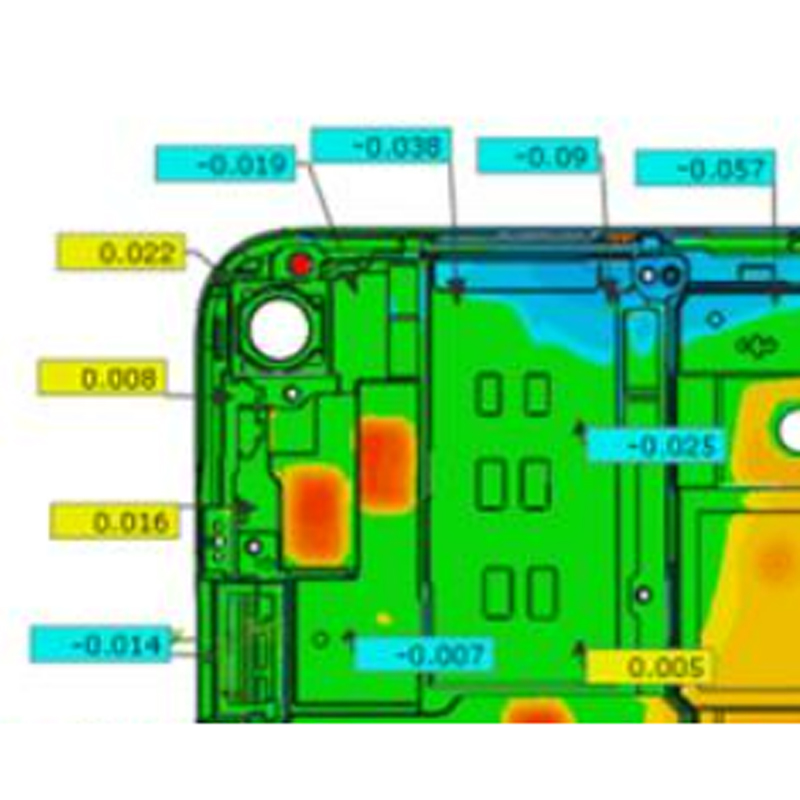

Engineering team will help you on optimize molding part design, GD&T check, material selection. 100% ensure the product with high production feasibility, quality, traceability

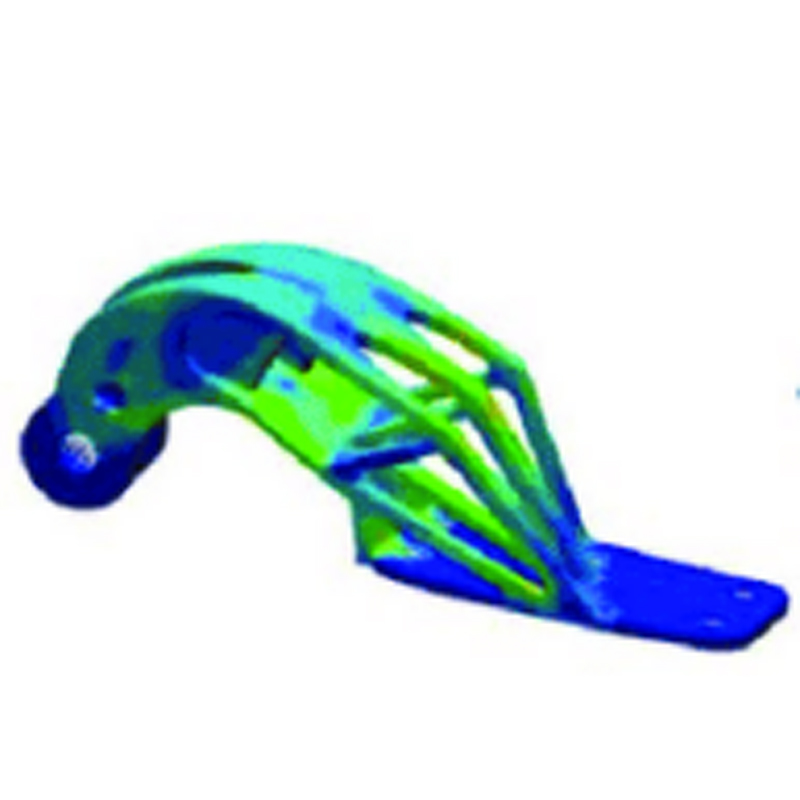

Simulation before Cutting Steel

For each projection, we will use mold-flow, Creo, Mastercam to simulate the injection molding process, machining process, drawing process to predict the issue before make physical samples

Complex Product Design

We have the top brand manufacturing facilities in injection molding, CNC machining and sheet metal fabrication. Which allows complex, high precision requirement product design

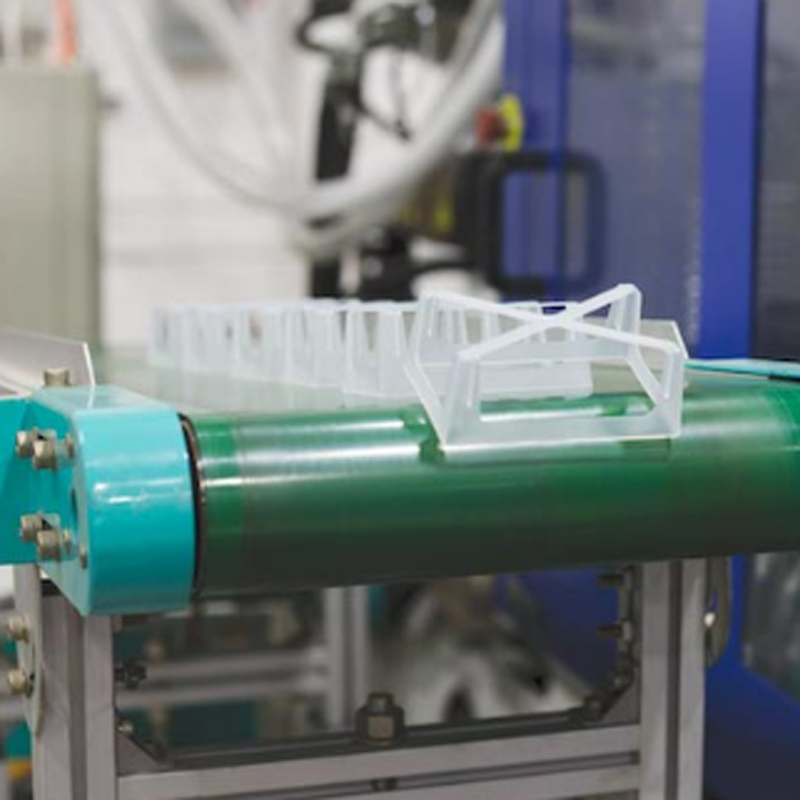

In house process

Injection mold making, Injection molding and second process of pad printing, heat staking, hot stamping, assembly are all in house, so you will have much low cost and reliable development lead time

Benefits of SLA Printing

High level of details

If you need accuracy, SLA is the additive manufacturing process you need to create highly detailed prototypes

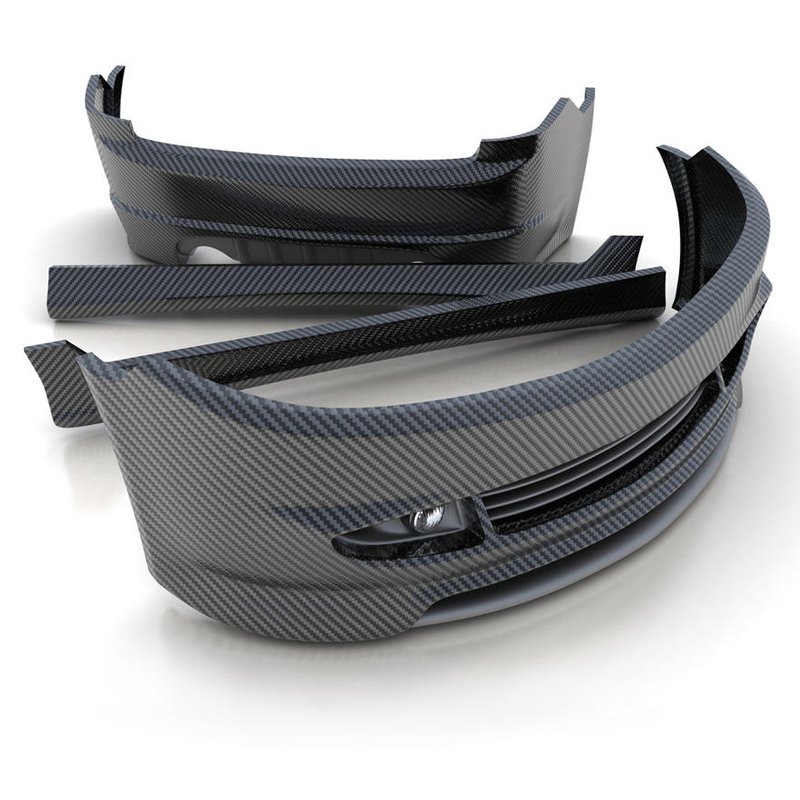

Various applications

From automotive to consumer products, many companies are using Stereolithography for rapid prototyping

Design freedom

Design-driven manufacturing allows you to produce complex geometries

SLA Application

Automotive

Healthcare and Medical

Mechanics

High Tech

Industrial Goods

Electronics

SLA vs SLS vs FDM

| Property Name | Stereolithography | Selective Laser Sintering | Fused Deposition Modeling |

| Abbreviation | SLA | SLS | FDM |

| Material type | Liquid (Photopolymer) | Powder (Polymer) | Solid (Filaments) |

| Materials | Thermoplastics (Elastomers) | Thermoplastics such as Nylon, Polyamide, and Polystyrene; Elastomers; Composites | Thermoplastics such as ABS, Polycarbonate, and Polyphenylsulfone; Elastomers |

| Max part size (in.) | 59.00 x 29.50 x 19.70 | 22.00 x 22.00 x 30.00 | 36.00 x 24.00 x 36.00 |

| Min feature size (in.) | 0.004 | 0.005 | 0.005 |

| Min layer thickness (in.) | 0.0010 | 0.0040 | 0.0050 |

| Tolerance (in.) | ±0.0050 | ±0.0100 | ±0.0050 |

| Surface finish | Smooth | Average | Rough |

| Build speed | Average | Fast | Slow |

| Applications | Form/fit testing, Functional testing, Rapid tooling patterns, Snap fits, Very detailed parts, Presentation models, High heat applications | Form/fit testing, Functional testing, Rapid tooling patterns, Less detailed parts, Parts with snap-fits & living hinges, High heat applications | Form/fit testing, Functional testing, Rapid tooling patterns, Small detailed parts, Presentation models, Patient and food applications, High heat applications |

SLA Advantage

Stereolithography Is Fast

Stereolithography Is Accurate

Stereolithography Works With Different Materials

Sustainability

Multi-Part Assemblies Are Possible

Texturing Is Possible

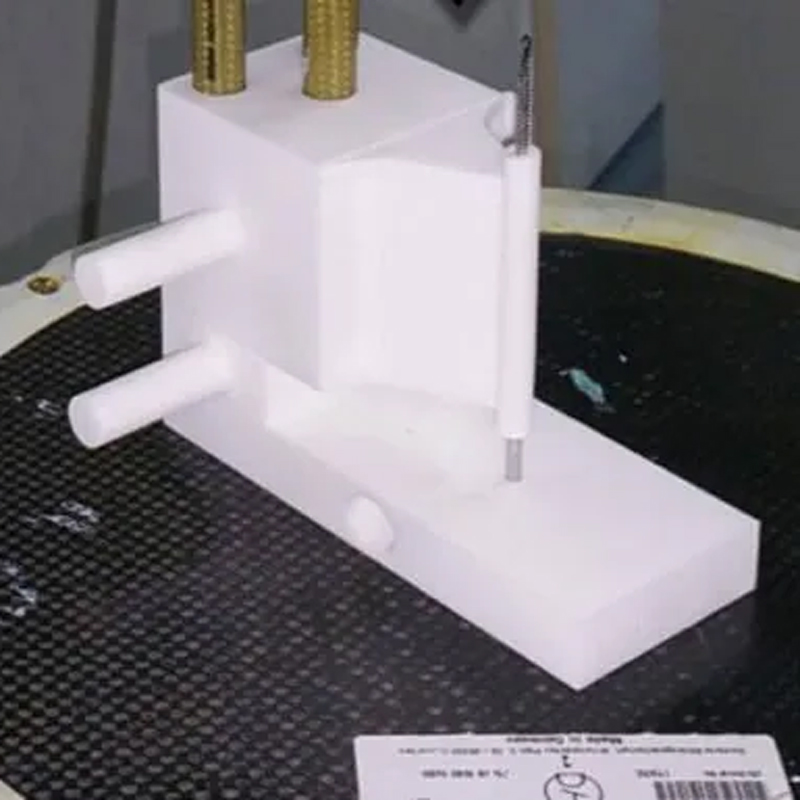

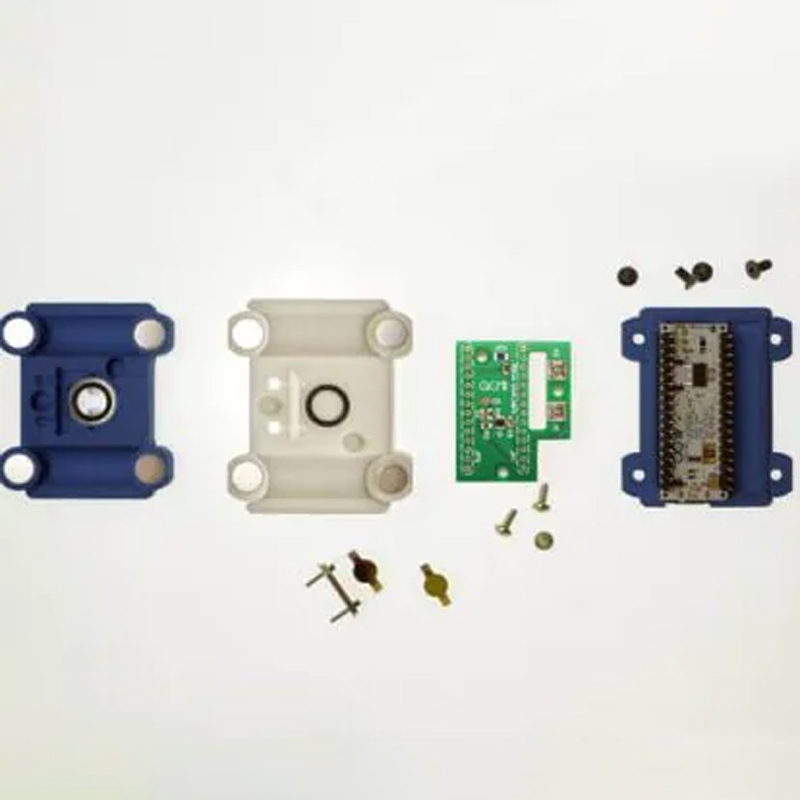

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers, hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Popular Design for 3d Injection Molding - CE Certification SLA products – FCE , The product will supply to all over the world, such as: Montpellier, Orlando, South Africa, Create Values,Serving Customer! is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!