Jekiseni Molding Service

Injiniya Nyanzvi uye Nhungamiro

Injiniya timu ichakubatsira iwe pakugadzirisa kuumba chikamu dhizaini, GD&T cheki, kusarudzwa kwezvinhu. 100% simbisa chigadzirwa nepamusoro kugadzirwa kugona, mhando, traceability

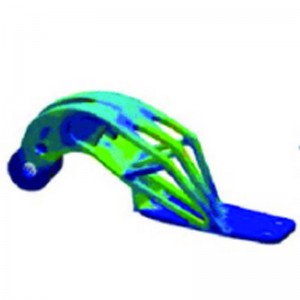

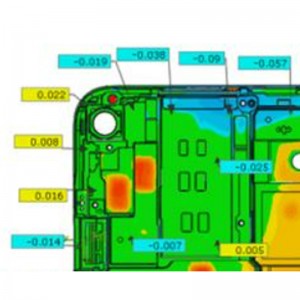

Simulation isati yacheka Simbi

Kune yega yega fungidziro, isu tichashandisa mold-kuyerera, Creo, Mastercam kutevedzera majekiseni ekuumba maitiro, machining maitiro, kudhirowa maitiro kufanotaura nyaya isati yaita sampuli dzemuviri.

Precise Complex Product Manufacturing

Isu tine yepamusoro mhando yekugadzira zvivakwa mukuumba jekiseni, CNC machining uye sheet simbi yekugadzira. Iyo inobvumira yakaoma, yakakwirira chaiyo inodiwa chigadzirwa dhizaini

In house process

Injection mold kugadzira, jekiseni kuumba uye yechipiri maitiro ekudhinda padhi, kupisa staking, kupisa kutsika, gungano zvese zviri mumba, saka uchave nemutengo wakaderera uye yakavimbika yekusimudzira nguva yekutungamira.

Available Process

Overmolding

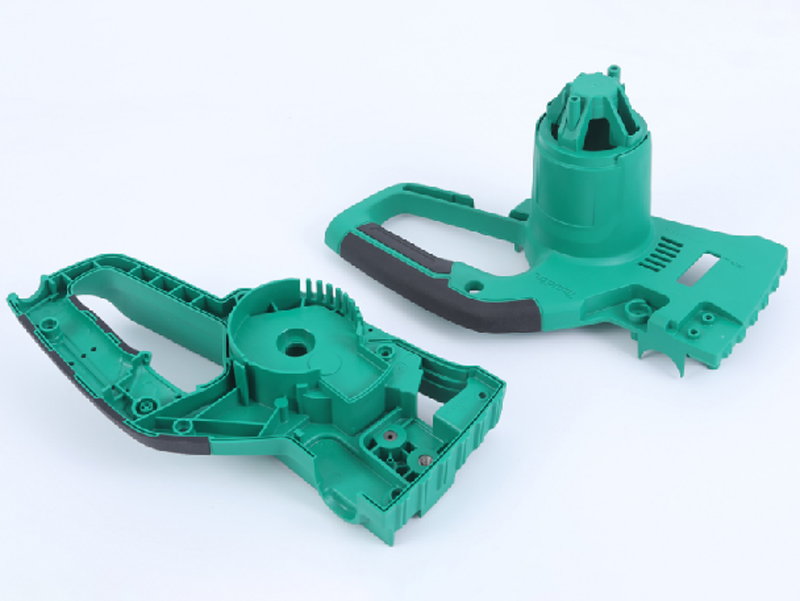

Overmolding inonziwo multi-k jekiseni molding. inzira yakasarudzika inosanganisa maviri kana akawanda zvinhu, mavara pamwechete. Iyo inzira yakanakisa yekuwana akawanda-mavara, akawanda-kuomarara, akawanda-layer & kubata kunzwa chigadzirwa. Zvakare shandiswa pane imwe chete pfuti ine muganhu waisakwanisa kuwanikwa chigadzirwa.

Overmolding

Overmolding inonziwo multi-k jekiseni molding. inzira yakasarudzika inosanganisa maviri kana akawanda zvinhu, mavara pamwechete. Iyo inzira yakanakisa yekuwana akawanda-mavara, akawanda-kuomarara, akawanda-layer & kubata kunzwa chigadzirwa. Zvakare shandiswa pane imwe chete pfuti ine muganhu waisakwanisa kuwanikwa chigadzirwa.

Liquid Silicone Rubber jekiseni kuumba

Liquid Silicone Rubber (LSR) yakakwira chaiyo Silicone yekugadzira nzira. Uye ndiyo chete nzira yekuve neyakajeka (yakajeka) chikamu cherubha. Silicone chikamu chakasimba kunyange 200degree temp. makemikari kuramba, zvokudya giredhi zvinhu.

Mukushongedza kwe mold

Mukushongedza mold (IMD) iri nyore uye inoshanda maitiro. Kushongedza kunoitwa mukati me mold pasina pre / yechipiri maitiro. Kushongedza kunopedzwa, kusanganisira bhachi rakaoma rekudzivirira, nekungopfura kamwe chete. Bvumira chigadzirwa ive netsika mapatani, gloss uye mavara.

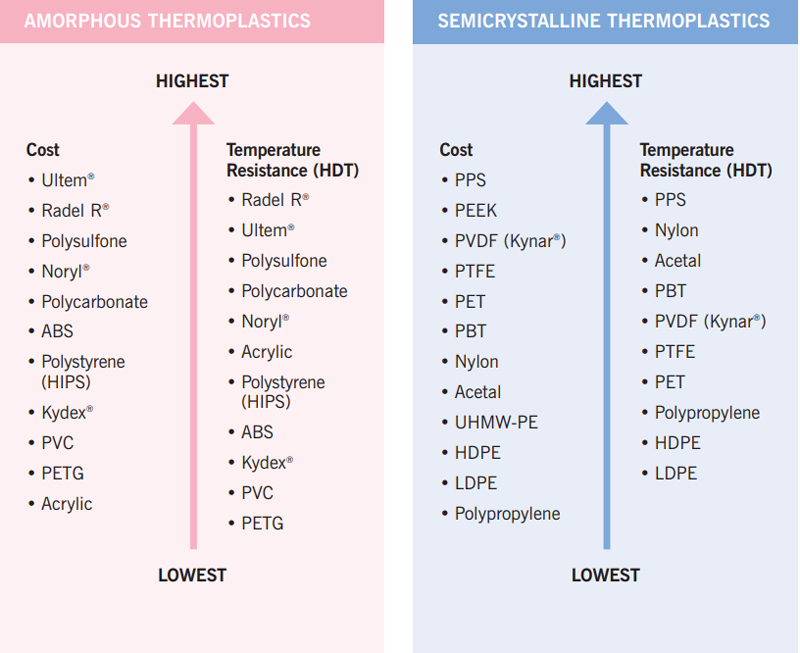

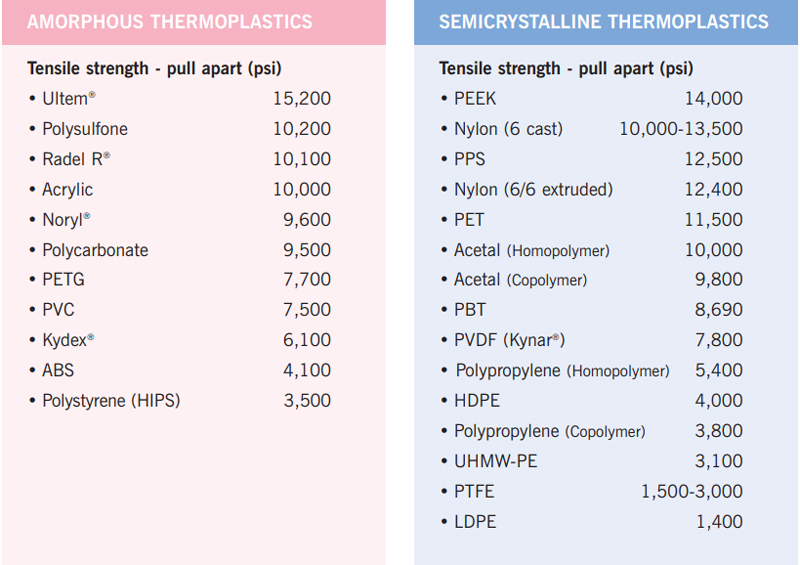

Kusarudzwa kwezvinhu

FCE ichakubatsira iwe kuwana yakanakisa zvinhu zvinoenderana nechigadzirwa chinodiwa uye mashandisiro. Pane zvakawanda zvesarudzo mumusika, isu tichazoenderana nemutengo unoshanda uye kugadzikana kwekutengesa ketani kukurudzira mhando uye giredhi resin.

Yakaumbwa chikamu Inopera

| Glossy | Semi-Glossy | Matt | Textured |

| SPI-A0 | SPI-B1 | SPI-C1 | MT (Moldtech) |

| SPI-A1 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| SPI-A2 | SPI-B3 | SPI-C3 | YS (Yick Sang) |

| SPI-A3 |

Plastic jekiseni Kuumba Mano

Secondary Processs

Kupisa Staking

Kupisa uye Kudzvanya simbi inoisa kana imwe yakaoma zvinhu chikamu muchigadzirwa. Mushure mokunge zvinhu zvakanyunguduka zvakasimba, zvinobatanidzwa pamwe chete. Yakajairika kune nzungu dzendarira.

Laser Engraving Maka mapatani pane chigadzirwa nelaser. Nelaser sensitive material, tinogona kuva newhite laser mark pane dema chikamu.

Pad Printing/screen kudhinda

Dhinda ingi pane chigadzirwa chepamusoro, kudhindisa kwemavara akawanda kunogamuchirwa.

NCVM uye Painting Kuve nemuvara wakasiyana, roughness, metallic effect uye anti-scratch surface effect. Kazhinji kune zvigadzirwa zve cosmetic.

Ultrasonic Plastic Welding

Joint maviri chikamu ne Ultrasonic simba, mutengo unoshanda, chisimbiso chakanaka uye chizoro.

FCE Injection molding solutions

Kubva papfungwa kuenda kuchokwadi

Prototype chishandiso

Nekukurumidza dhizaini yekusimbisa ine chaiyo zvinhu uye maitiro, Fast prototype simbi yekushandisa ndiyo yakanaka mhinduro kwayo. Inogona kunge iri bhiriji rekugadzira zvakare.

- Hapana muganhu weodha shoma

- Complex dhizaini inogoneka

- 20k kupfura chishandiso hupenyu hwakavimbiswa

Production tooling

Kazhinji nesimbi yakaoma, inopisa mumhanyi system, simbi yakaoma. Upenyu hwekushandisa hunosvika mazana mashanu kusvika kumamiriyoni epfuti. Mutengo wechigadzirwa cheyuniti wakadzikira zvakanyanya, asi mold mutengo wakakwira kupfuura prototype chishandiso

- Kupfuura miriyoni pfuti

- High kunyatsoshanda & kumhanya mutengo

- High chigadzirwa chemhando

Typical Development Process

Quote neDFx

Tarisa iwe zvinodiwa data uye maapplication, ipa mamiriro ekotesheni nemazano akasiyana. Simulation report inopihwa in parallel

Wongorora prototype (imwe nzira)

Gadzira chishandiso chekukurumidza (1 ~ 2wks) kuumba prototype samples yekugadzira uye kuumba maitiro ekuongorora.

Kugadzira mold kukura

Iwe unogona kutanga ramp kumusoro nekukurumidza neiyo prototype chishandiso. Kana kudiwa kuri pamusoro pemamiriyoni, tanga kugadzira mold ine yakawanda-cavitation yakafanana, izvo zvinotora approx. 2 ~ 5 mavhiki

Dzokorora Order

Kana iwe wakatarisa kudiwa, tinogona kutanga kutumira mukati me2days. Hapana kurongeka kwekutarisa, tinogona kutanga kutumira zvishoma se3days

Q&A

Chii chinonzi injection molding?

Jekiseni molding zvidimbu zviviri zvakakura zvesimbi zvinouya pamwechete, purasitiki kana rabha zvinhu zvinobayiwa mugomba. Zvinhu zvepurasitiki zviri kubaiwa zvinonyungudutswa, hazvina kunyatsodziiswa; Zvinhu zvakatsikirirwa mujekiseni kuburikidza negedhi remumhanyi. Sezvo zvinhu zvacho zvinomanikidzwa, zvinopisa uye zvinotanga kuyerera mumamolds. Kana ichinge yatonhora, hafu mbiri inoparadzana zvakare uye chikamu chinobuda. Dzokorora zviito zvimwechete kubva pakuvhara mold uye kuvhura mold sedenderedzwa rimwe, uye une majekiseni akaumbwa akagadzirira.

Ndeapi maindasitiri anoshandisa jekiseni molding?

Minda yakasiyana-siyana inogona kushandiswa mune zvinotevera:

Medical & Pharmaceutical

Electronics

Kuvaka

Chikafu & Chinwiwa

Automotive

Toys

Consumer Goods

Mhuri

Ndedzipi mhando dzemajekiseni ekuumba maitiro?

Kune akati wandei marudzi ejekiseni molding maitiro, anosanganisira:

Custom epurasitiki jekiseni kuumba

Overmolding

Isa kuumba

Gasi-inobatsira jekiseni molding

Liquid silicone rabha jekiseni kuumba

Metal jekiseni kuumba

Reaction jekiseni kuumba

Jekiseni mold rinotora nguva yakareba sei?

Zvinoenderana nezvakati wandei zvinhu: mold zvinhu, huwandu hwematenderedzwa, ekushanda mamiriro, uye kutonhora / kubata kudzvanywa nguva pakati pekugadzira inomhanya.

Ndeupi musiyano uripo pakati pekugadzira nekuumba?

Kunyangwe zvakada kufanana, mutsauko uripo pakati pekugadzira nekuumba unouya kune avo akasiyana maficha uye mabhenefiti, zvichienderana nekushandiswa kwavari kushandiswa. Jekiseni molding inonyanya kukodzera kune makuru ekugadzira anomhanya. Thermoforming, inonyanya kukodzera kupfupika kwekugadzira dhizaini yakakura uye inosanganisira kuumba mashizha epurasitiki anopisa kusvika pamusoro peforoma.