Overmolding Service

Injiniya Nyanzvi uye Nhungamiro

Injiniya timu ichakubatsira iwe pakugadzirisa kuumba chikamu dhizaini, GD&T cheki, kusarudzwa kwezvinhu. 100% simbisa chigadzirwa nepamusoro kugadzirwa kugona, mhando, traceability

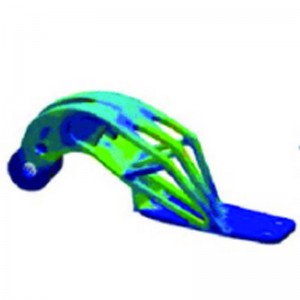

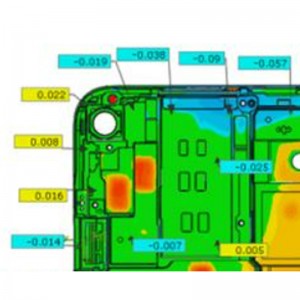

Simulation isati yacheka Simbi

Kune yega yega fungidziro, isu tichashandisa mold-kuyerera, Creo, Mastercam kutevedzera majekiseni ekuumba maitiro, machining maitiro, kudhirowa maitiro kufanotaura nyaya isati yaita sampuli dzemuviri.

Precise Complex Product Manufacturing

Isu tine yepamusoro mhando yekugadzira zvivakwa mukuumba jekiseni, CNC machining uye sheet simbi yekugadzira. Iyo inobvumira yakaoma, yakakwirira chaiyo inodiwa chigadzirwa dhizaini

In house process

Injection mold kugadzira, jekiseni kuumba uye yechipiri maitiro ekudhinda padhi, kupisa staking, kupisa kutsika, gungano zvese zviri mumba, saka uchave nemutengo wakaderera uye yakavimbika yekusimudzira nguva yekutungamira.

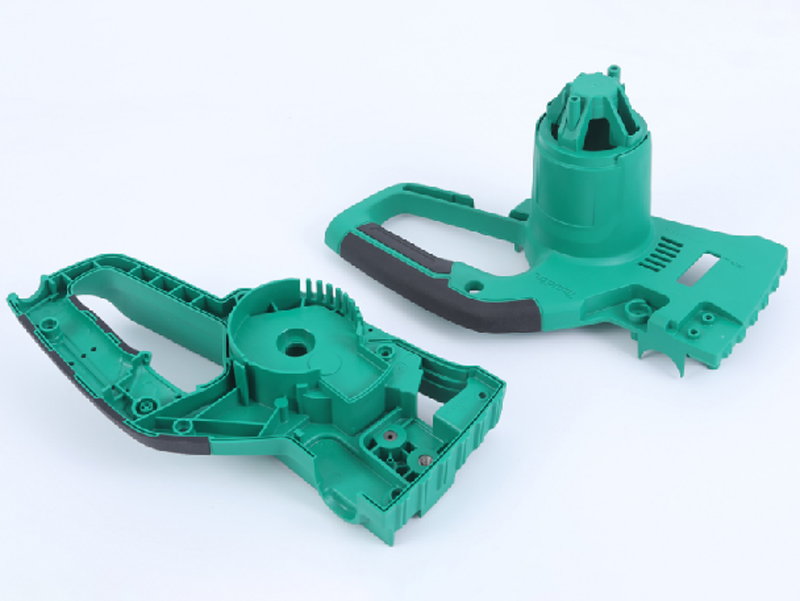

Overmolding (Multi-K jekiseni molding)

Overmolding inonziwo multi-k jekiseni molding. inzira yakasarudzika inosanganisa maviri kana akawanda zvinhu, mavara pamwechete. Iyo inzira yakanakisa yekuwana akawanda-mavara, akawanda-kuomarara, akawanda-layer & kubata kunzwa chigadzirwa. Ishandiswewo papfuti imwe chete iyo maitiro asina kukwanisa kuwanikwa chigadzirwa. Rudzi rwakajairika rwekuumbwa kweakawanda-pfuti kuumba kaviri-kupfura jekiseni, kana izvo zvinozivikanwa se2K jekiseni moulding.

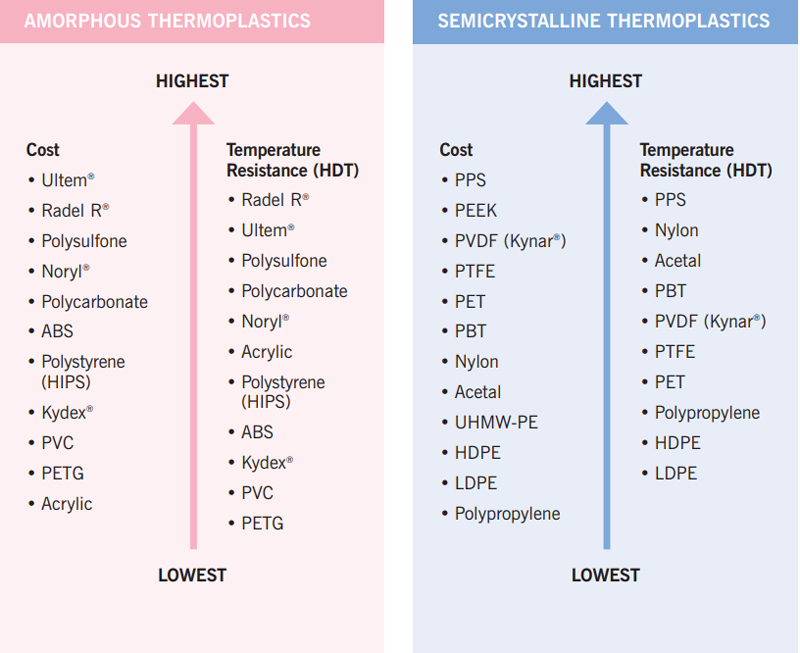

Kusarudzwa kwezvinhu

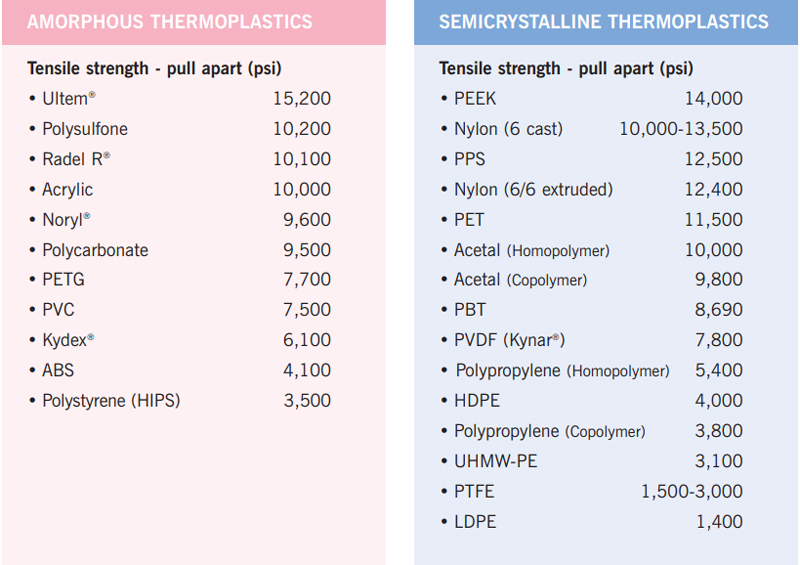

FCE ichakubatsira iwe kuwana yakanakisa zvinhu zvinoenderana nechigadzirwa chinodiwa uye mashandisiro. Pane zvakawanda zvesarudzo mumusika, isu tichazoenderana nemutengo unoshanda uye kugadzikana kwekutengesa ketani kukurudzira mhando uye giredhi resin.

Yakaumbwa chikamu Inopera

| Glossy | Semi-Glossy | Matt | Textured |

| SPI-A0 | SPI-B1 | SPI-C1 | MT (Moldtech) |

| SPI-A1 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| SPI-A2 | SPI-B3 | SPI-C3 | YS (Yick Sang) |

| SPI-A3 |

FCE Injection molding solutions

Kubva papfungwa kuenda kuchokwadi

Prototype chishandiso

Nekukurumidza dhizaini yekusimbisa ine chaiyo zvinhu uye maitiro, Fast prototype simbi yekushandisa ndiyo yakanaka mhinduro kwayo. Inogona kunge iri bhiriji rekugadzira zvakare.

- Hapana muganhu weodha shoma

- Complex dhizaini inogoneka

- 20k kupfura chishandiso hupenyu hwakavimbiswa

Production tooling

Kazhinji nesimbi yakaoma, inopisa mumhanyi system, simbi yakaoma. Upenyu hwekushandisa hunosvika mazana mashanu kusvika kumamiriyoni epfuti. Mutengo wechigadzirwa cheyuniti wakadzikira zvakanyanya, asi mold mutengo wakakwira kupfuura prototype chishandiso

- Kupfuura miriyoni pfuti

- High kunyatsoshanda & kumhanya mutengo

- High chigadzirwa chemhando

Key Benefits

Yakaoma Dhizaini Kugamuchirwa

Multi-K jekiseni molding inogadzira zvikamu zvakaoma zvinokwanisa kuita mamwe mabasa

Mutengo Chengetedza

Yakaumbwa sechikamu chimwe chakabatanidzwa, bvisa nzira yekubatanidza kuderedza kuungana uye mutengo webasa

Mechanical simba

Multi-K jekiseni kuumba inopa yakasimba uye yakasimba chigadzirwa chigadzirwa, yakagadziridzwa chikamu chesimba uye chimiro

Multi Color Cosmetic

Kugona kupa yakanaka-yakawanda-mavara chigadzirwa, inobvisa kudiwa kwechipiri maitiro senge pendi kana plating

Typical Development Process

Quote neDFx

Tarisa iwe zvinodiwa data uye maapplication, ipa mamiriro ekotesheni nemazano akasiyana. Simulation report inopihwa in parallel

Wongorora prototype (imwe nzira)

Gadzira chishandiso chekukurumidza (1 ~ 2wks) kuumba prototype samples yekugadzira uye kuumba maitiro ekuongorora.

Kugadzira mold kukura

Iwe unogona kutanga ramp kumusoro nekukurumidza neiyo prototype chishandiso. Kana kudiwa kuri pamusoro pemamiriyoni, tanga kugadzira mold ine yakawanda-cavitation yakafanana, izvo zvinotora approx. 2 ~ 5 mavhiki

Dzokorora Order

Kana iwe wakatarisa kudiwa, tinogona kutanga kutumira mukati me2days. Hapana kurongeka kwekutarisa, tinogona kutanga kutumira zvishoma se3days

Q&A

Chii chinonzi Overmolding?

Overmolding ipurasitiki yekugadzira maitiro apo zvinhu zviviri (Plastiki kana Metal) zvakabatanidzwa pamwechete. Iko kusungirirwa kunowanzoita kemikari kubatana, asi dzimwe nguva mechanical bonding inosanganiswa nemakemikari bonding. Chinhu chekutanga chinonzi Substrate, uye chechipiri chinyorwa chinonzi Chinotevera. Overmolding iri kuwedzera mukurumbira nekuda kwekuderedzwa kwemutengo wekugadzira uye nekukurumidza kutenderera nguva. Pamusoro peizvozvo, iwe unozogona kuwana aesthetically inokwezva zvigadzirwa muOvermolding process.

Kaviri kupfura nzvimbo yakanakisa yakashandiswa?

- Mabhatani uye switch, zvibato, grips uye caps.

- Multi-mavara zvigadzirwa kana pendi logos.

- Zvikamu zvakawanda zvinoshanda semapedhi eruzha uye damper yevibration.

- Zvemotokari, zvekurapa uye zvevatengi maindasitiri.

Overmolding application

Plastiki Pamusoro Pepurasitiki

Yekutanga yakasimba yepurasitiki substrate inoumbwa uyezve imwe yakasimba purasitiki inoumbwa pairi kana kutenderedza substrate. Mazhinji mavara akasiyana uye resin anogona kuiswa.

Rubber Pamusoro pePlastiki

Chekutanga purasitiki yakaoma substrate inoumbwa uyezve rabha yakapfava kana TPE inoumbwa pamusoro kana kutenderedza substrate.

Plastiki Pamusoro Pesimbi

Chekutanga simbi substrate inogadzirwa, inokandwa kana kuumbwa uyezve iyo substrate inopinzwa mumudziyo uye plastiki inoumbwa pairi kana kutenderedza simbi. Inowanzoshandiswa kutora zvikamu zvesimbi muchikamu chepurasitiki.

Rubber Pamusoro Pesimbi

Chekutanga simbi substrate inogadzirwa, inokandwa, kana kuumbwa uyezve iyo substrate inopinzwa muchishandiso uye rabha kana TPE inoumbwa pairi kana kutenderedza simbi. Inowanzoshandiswa kupa nzvimbo yakapfava yekubata.