CNC Machining Service

CNC Machining Inowanikwa Maitiro

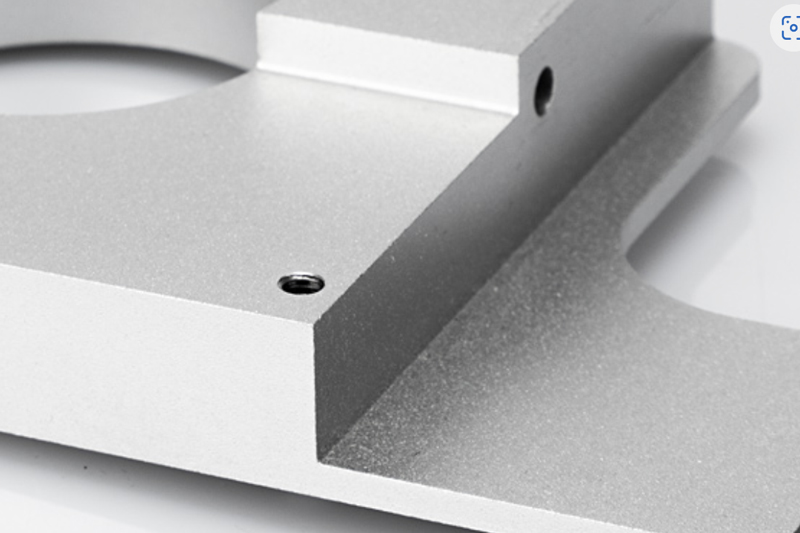

CNC Milling Service

Iine anopfuura makumi mashanu seti ye3, 4, uye 5-axis CNC michina yekupa iyo yakanyanya kushivirira inosvika ± 0.0008 ″ (0.02 mm) Precision CNC milling zvikamu. Online muchina shopu ye prototype machining uye kugadzira.

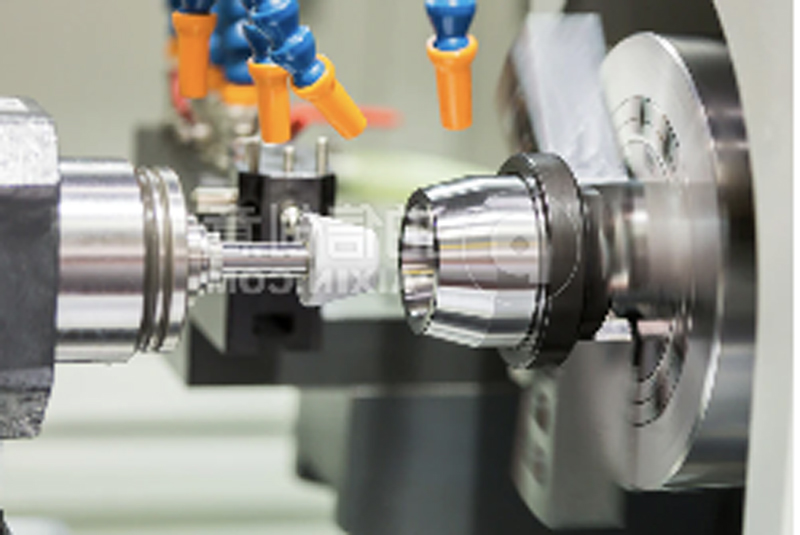

CNC Turning Service

80+ CNC Lathes uye CNC inoshandura nzvimbo, inogona kupa inodhura-inoshanda chaiyo machining masevhisi nemhinduro inokurumidza. 15+ makore nyanzvi mainjiniya kutsigira neakaoma zvigadzirwa.

Electrical Discharge Machining (EDM)

Iyo isiri-yekubata machining nzira yezvimiro zvakapfava. mhando mbiri dzeMagetsi Dicharge Machining (EDM) maitiro atinopa, Wire EDM uye Sinker EDM. Maitiro acho anobatsira pakucheka mahomwe akadzika uye akaomarara maficha senge magiya nemakomba ane kiyi.

CNC Machining Applications

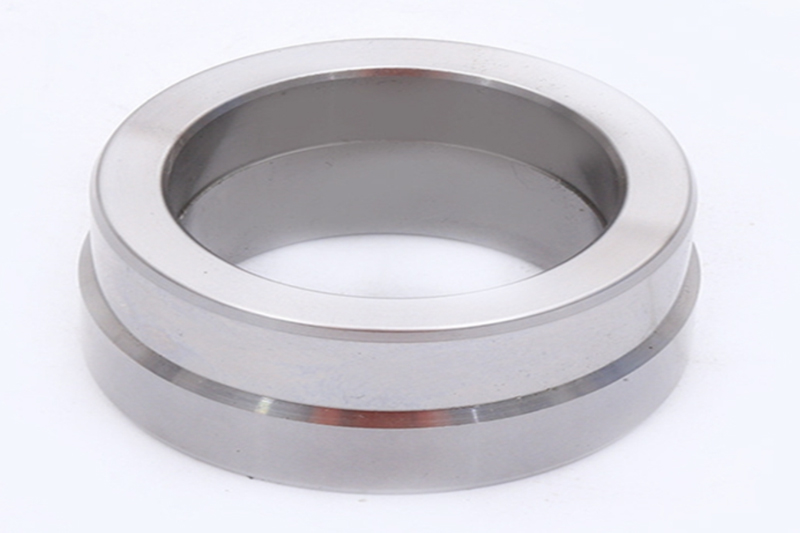

Rapid Tooling

CNC machining mhinduro yakakwana yekugadzira zvigadziriso kana mold. CNC machining inogona kucheka yakakwira akasiyana akazara dense, yakasimba zvinhu sealuminium 5052 uye simbi isina tsvina.

Rapid Prototyping

Prototypes kuve akagadzirira mu1 zuva. Isu tine makumi maviri+ ane hunyanzvi machinists kutsigira nekukurumidza uye emhando yepamusoro prototypes. Yakasiyana-siyana inokwanisika simbi alloys uye mapurasitiki anogona kuiswa kune prototypes.

Kupedzisa-Kushandisa Kugadzirwa

Kushivirira kwakadzikama se +/- 0.001”, sarudzo dzezvinhu zvinogoneka uye nzira dzakasiyana dzekurapa dzepamusoro dzinoita kuti CNC igadzirise tekinoroji yakanakisa yezvikamu zvekushandisa-magumo.

CNC Machining Zvishandiso Sarudzo----Simbi

FCE ichakubatsira iwe kuwana yakanakisa zvinhu zvinoenderana nechigadzirwa chinodiwa uye mashandisiro. Sarudza pakati pekutsanya uye zvinodhura-zvinobudirira sarudzo kuti uwane yakanakisa zvinhu.

·CNC Machining Aluminium Alloys

Aluminium 6061

Aluminium 5052

Aluminium 2024

Aluminium 6063

Aluminium 7050

Aluminium 7075

Aluminium MIC-6

·CNC Machining Copper Alloys

Mhangura 101

Mhangura C110

·CNC Machining Bronze Alloys

Mhangura C932

·CNC Machining Brass Alloys

Mhangura 260

Mhangura 360

·CNC Machining Stainless Steel Alloys

Nitronic 60 (218 SS)

Stainless Simbi 15-5

Stainless Simbi 17-4

Stainless Simbi 18-8

Stainless Simbi 303

Stainless Simbi 316/316L

Stainless Simbi 416

Stainless Simbi 410

Stainless Simbi 420

Stainless Simbi 440C

· CNC Machining Steel Alloys

Simbi 1018

Simbi 1215

Simbi 4130

Simbi 4140

Simbi 4140PH

Simbi 4340

Simbi A36

·CNC Machining Titanium Alloys

Titanium (Grade 2)

Titanium (Grade 5)

·CNC Machining Zinc Alloys

Zinc Alloy

CNC Machining Materials Sarudzo---- Plastiki

FCE ichakubatsira iwe kuwana yakanakisa zvinhu zvinoenderana nechigadzirwa chinodiwa uye mashandisiro. Sarudza pakati pekutsanya uye zvinodhura-zvinobudirira sarudzo kuti uwane yakanakisa zvinhu.

·ABS

ABS inogadzirwa nyore nyore kuburikidza neyakajairwa machining matekiniki, senge kutendeuka, kugaya, kuchera uye kusaha.

·Acrylic

Girazi rakajeka-rakafanana nepurasitiki, inowanzoshandiswa kushandiswa kwekunze. Zvakanaka kupfeka uye kubvarura zvinhu.

·Delrin (Acetal)

Delrin ine yakanaka kunyorova kuramba, yakakwira kupfeka-kupokana, uye kuderera kwakadzika.

·Garolite G10

G10 yakasimba, inogoneka uye inodzivirira magetsi. Yakagadzirwa ne-flame-retardant epoxy resin ine fiberglass yekusimbisa jira.

·HDPE

High-density polyethylene ipurasitiki yakanyorova uye isingagadzirike kemikari ine simba rakanaka. Inowanzo kushandiswa kwekunze kwekushandisa, midziyo isina mvura uye zvisimbiso.

·Naironi 6/6

Nylon 6/6 yakawedzera simba remagetsi, kusimba, kugadzikana kwakanaka pasi pekupa kupisa uye / kana makemikari kuramba.

PC (Polycarbonate)

PC ine yepamusoro michina uye zvimiro. Inoshandiswa zvakanyanya mumotokari, aerospace, uye mamwe maapplication anoda kusimba uye kugadzikana.

·PEEK

PEEK inowanzoshandiswa seyakareruka imwe nzira yezvikamu zvesimbi. Inowanzoshandiswa mukupisa-kupisa, kushandiswa kwepamusoro-soro. PEEK inoramba makemikari, kupfeka, uye unyoro, inopa yakanakisa kusimba simba,

· Polypropylene

Polypropylene ikemikari kana corrosion resistance. Iine zvinhu zvemagetsi zvakanakisa uye zvishoma kana kusatora mwando. Inotakura mitoro yakareruka kwenguva yakareba mukupisa kwakasiyana-siyana.

·PTFE (Teflon)

PTFE inodarika mapurasitiki mazhinji kana zvasvika pakuramba kwemakemikari uye kuita mukupisa kwakanyanya. Inopikisa zvinonyungudutsa zvakawanda uye insulator yemagetsi yakanakisa.

·UHMW PE

Ultra-yakakwirira molecular uremu polyethylene. UHMW PE haitore hunyoro uye inopa yakasarudzika musanganiswa wekupfeka uye kuonda kuramba, yakakwirira makemikari kuramba, kuderera kwepasi friction, yakakwirira simba simba.

·PVC

PVC inowanzo shandiswa munzvimbo dzakafumurwa kune zvinwiwa kana kuti inoda kuvharwa kwemagetsi. Uye zvakare yakanyanya makemikari-resistant synthetic plastiki

CNC Machining Surface Inopedza

Standard (As-Milled)

Ndiyo inokurumidza kuchinja machining process. Iine hukasha hwepamusoro hwe3.2 μm (126 μin). Zvose zvinopinza zvinobviswa, uye zvikamu zvinobviswa. Zvishandiso zviratidzo zvinoonekwa.

Bead Blast

Chikamu chepamusoro chinosara chine chitarisiko chakatsetseka, chine matte

Tumbled

Ndiyo inokurumidza kuchinja machining process. Iine hukasha hwepamusoro hwe3.2 μm (126 μin). Zvose zvinopinza zvinobviswa, uye zvikamu zvinobviswa. Zvishandiso zviratidzo zvinoonekwa.

Anodized

Zvikamu zvinogona anodized mune akawanda akasiyana mavara-Akajeka, dema, grey, tsvuku, bhuruu, goridhe.

Passivation

Zvikamu zvinogona kuve anodized mumarudzi akawanda akasiyana-matema, akajeka, matsvuku, uye goridhe.

Powder Coat

Zvikamu zvinogona kuve anodized mumarudzi akawanda akasiyana-matema, akajeka, matsvuku, uye goridhe.

CNC Machining Dhizaini Mazano

| Feature | Tsanangudzo |

| Internal corner fillets | Dhizaina mafiritsi emakona emukati kuti ave 0.020”- 0.050” akakura kupfuura saizi yekuboorera yeradii. Tevedzera chibooreso dhayamita kusvika pakadzika reshiyo ye1:6 (1:4 inokurudzirwa) segwara remukati rekona radii. |

| Floor fillets | Dhizaina mafiritsi epasi madiki pane mafirita ekona kuti abvumire chishandiso chimwe chete kujekesa zvinhu kubva mukati. |

| Undercuts | Gara uchigadzira undercuts kune akajairwa saizi uye kure nemakona kuitira kuti asvike nekucheka chishandiso. |

| Kudzika kwegomba rakatepwa/shinda | Ipa chishandiso chekuchenesa zvishoma kudarika kudzika kwegomba kuti uve nechokwadi chetambo dzakakwana. |

| Kuoma kunzwisisa | Chengetedza huwandu hwekucheka kudiki kune hushoma kuderedza CNC machining mutengo; chete dhizaini mune anodiwa maficha kuenzanisa basa nekunaka. |

CNC Machining Tolerances

| Feature | Tsanangudzo |

| Maximum Chikamu Saizi | Zvigayo zvinosvika 80" x 48" x 24" (2,032 x 1,219 x 610 mm). Rongedza zvikamu kusvika pa62" (1,575 mm) kureba uye 32" (813 mm) dhayamita. |

| Standard Lead Time | 3 mazuva ekushanda |

| General Tolerances | Kushivirira pasimbi kuchaitwa ku +/- 0.005" (+/- 0.127 mm) maererano neISO 2768 kunze kwekunge zvatsanangurwa. Mapurastiki nemacomposites zvichave +/- 0.010”. |

| Precision Tolerances | FCE inogona kugadzira uye kuongorora kune kushivirira kwakasimba maererano nemaitiro ako ekudhirowa kusanganisira GD&T callouts. |

| Minimum Feature Size | 0.020” (0.50 mm). Izvi zvinogona kusiyana zvichienderana nechikamu chejometri uye zvinhu zvakasarudzwa. |

| Threads uye Tapped Holes | FCE inogona kugarisa chero saizi yeshinda. Isu tinogonawo kugadzira tambo dzetsika; izvi zvinoda ongororo yemanyorero. |

| Edge Condition | Mheto dzakapinza dzakatyoka uye dzakabviswa nekusarudzika |

| Surface Finish | Iyo yakajairwa kupedzisa ndeye se-yakagadzirwa: 125 Ra kana zvirinani. Dzimwe sarudzo dzekupedzisa dzinogona kutsanangurwa kana uchiwana quote. |

Yedu Quality Promise