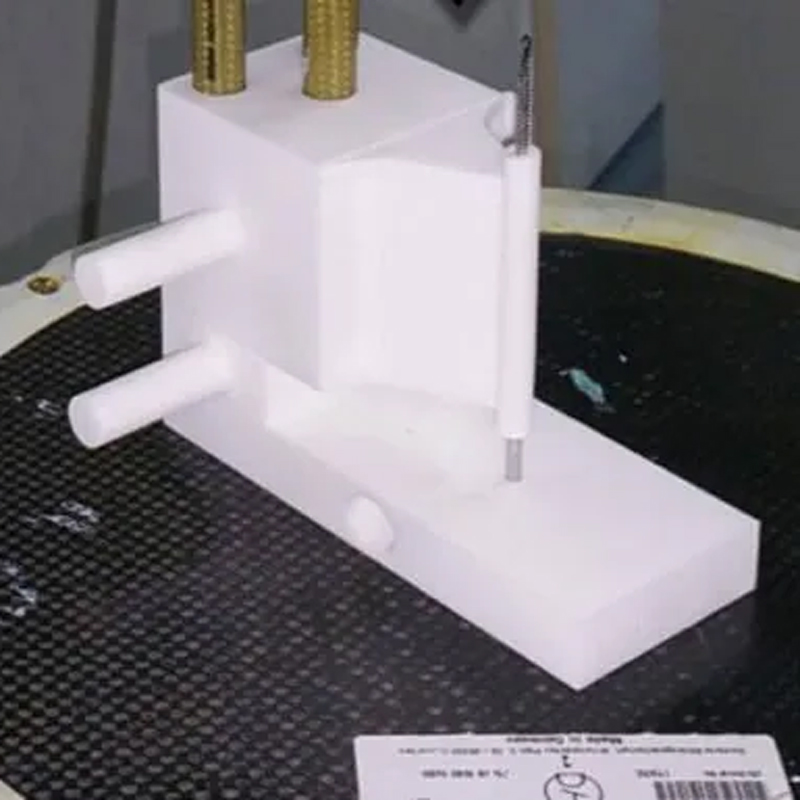

SLA

SLA design hagaha

Xallinta daabacaadda

Dhumucda lakabka caadiga ah: 100 µm Saxnimada: ± 0.2% (oo leh xad hoose ± 0.2 mm)

Xaddidaadda cabbirka 144 x 144 x 174 mm dhumucda ugu yar Dhumucda gidaarka ugu yar 0.8mm - oo leh 1:6 saamiga

Embossing iyo Embossing

Dhererka ugu yar iyo tafaasiisha ballaca: 0.5 mm

Ku xardhay: 0.5 mm

Xiran & mugga isdhaafsan

Qaybaha xidhan? Laguma talin in la isku xidho? Laguma talin

Xayiraadda xubinta

Golaha? Maya

Khibrada Injineerinka iyo Hagidda

Kooxda Injineerinka ayaa kaa caawin doona sidii aad u wanaaji lahayd nashqadeynta qaybta naqshadaynta, hubinta GD&T, xulashada agabka. 100% hubi badeecada leh suurtogalnimada wax soo saarka sare, tayada, raadinta

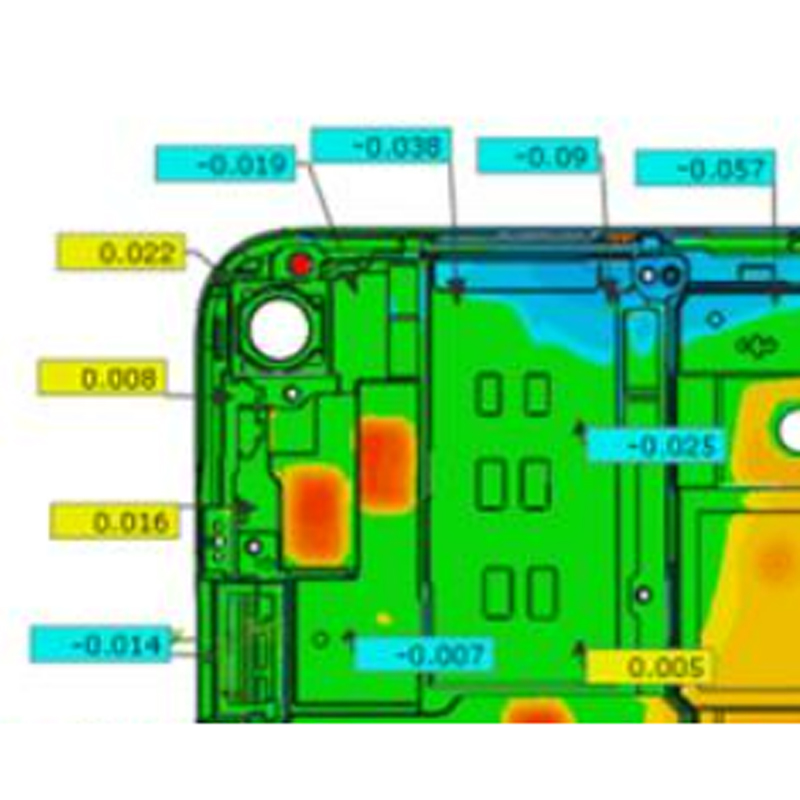

Jilidda ka hor inta aan la jarin Birta

Saadaasha kasta, waxaan u isticmaali doonaa qulqulka caaryada, Creo, Mastercam si aan u ekayno habka qaabaynta duritaanka, habka mashiinada, habka sawirista si loo saadaaliyo arrinta ka hor inta aan la samayn muunado jireed

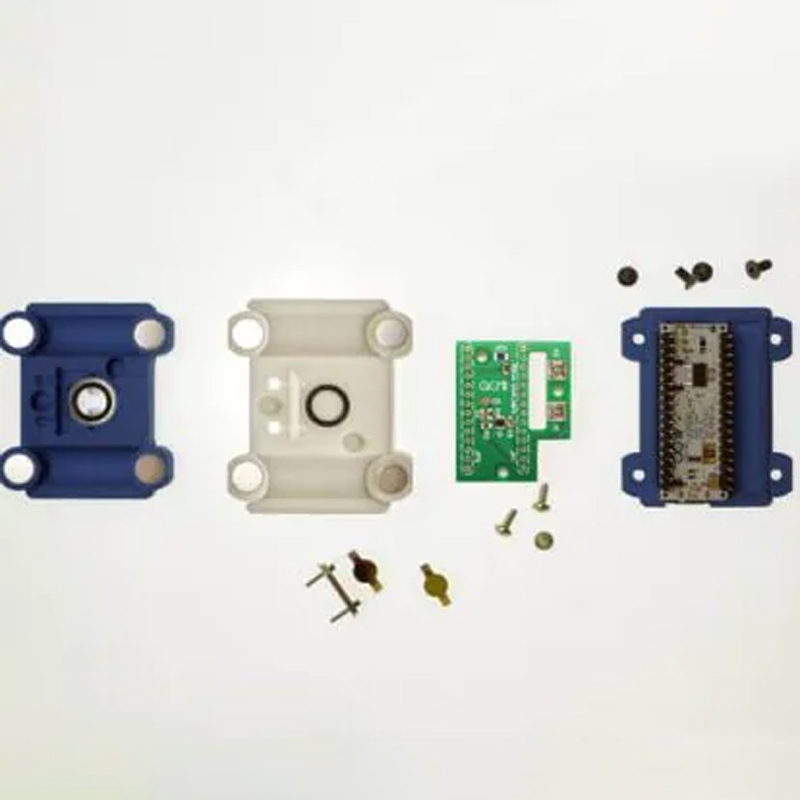

Naqshadaynta Alaabta Kakan

Waxaan haynaa tas-hiilaadka wax soo saarka summada ugu sarreeya ee naqshadaynta duritaanka, mashiinnada CNC iyo samaynta biraha xaashida ah. Kaas oo u oggolaanaya naqshadaynta alaabta adag, shuruudda saxda ah ee sare

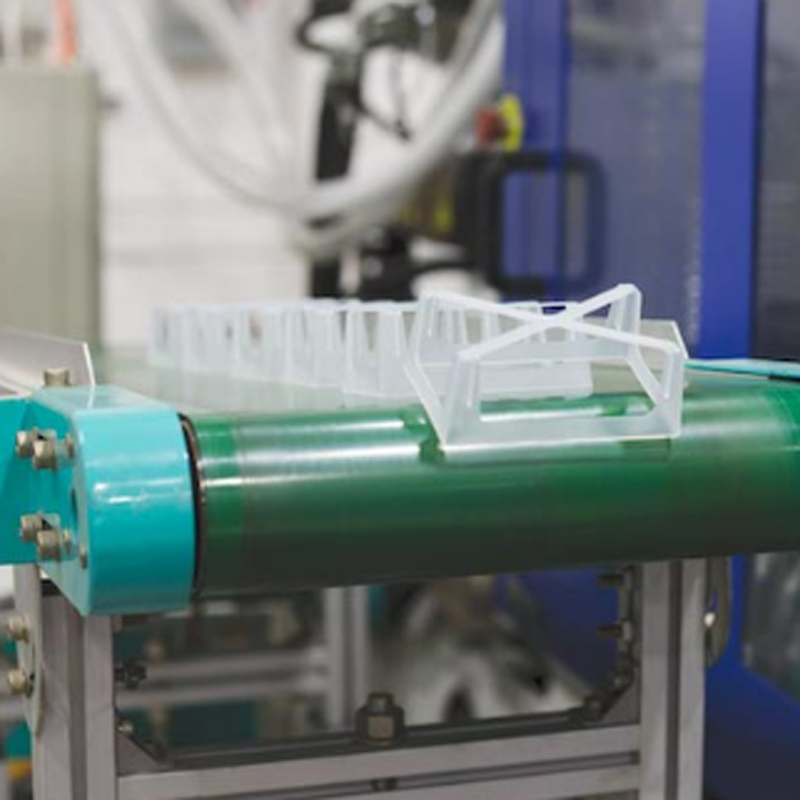

Habka guriga

Samaynta caaryada duritaanka, qaabaynta cirbadaha iyo habka labaad ee daabacaadda suufka, kulaylka, stamping kulul, isu imaatinka dhamaantood waxay ku yaalaan guriga, markaa waxaad yeelan doontaa qiimo jaban iyo waqti horumarineed oo la isku halayn karo

Faa'iidooyinka Daabacaadda SLA

Heerka sare ee faahfaahinta

Haddii aad u baahan tahay saxsanaan, SLA waa habka wax soo saarka wax soo saarka ee aad u baahan tahay si aad u abuurto tusaalooyin aad u faahfaahsan

Codsiyo kala duwan

Laga soo bilaabo baabuurta ilaa alaabta macaamiisha, shirkado badan ayaa u isticmaalaya Stereolithography si ay si degdeg ah u daabacaan

Xornimada naqshadeynta

Wax-soo-saarka naqshadaynta ayaa kuu oggolaanaya inaad soo saarto joomatariyo adag

Codsiga SLA

Baabuur

Daryeelka Caafimaadka iyo Caafimaadka

Makaanikada

Farsamada sare

Alaabooyinka Warshadaha

Elektrooniga

SLA vs SLS vs FDM

| Magaca Hantida | Stereolithography | Xulashada Laser Sintering | Qaabaynta Dhigista Fudud |

| Soo gaabinta | SLA | SLS | FDM |

| Nooca walxaha | Dareere (Photopolimer) | Budada (Polymer) | Adag (Filaments) |

| Qalabka | Thermoplastics (Elastomers) | Thermoplastics sida Naylon, Polyamide, iyo Polystyrene; Elastomers; Isku-dhafka | Thermoplastics sida ABS, Polycarbonate, iyo Polyphenylsulfone; Elastomers |

| Cabirka qaybta ugu badan (gud ahaan) | 59.00 x 29.50 x 19.70 | 22.00 x 22.00 x 30.00 | 36.00 x 24.00 x 36.00 |

| Cabirka sifada ugu yar (gud.) | 0.004 | 0.005 | 0.005 |

| Dhumucda lakabka ugu yar (gud.) | 0.0010 | 0.0040 | 0.0050 |

| Dulqaadasho (gudasho) | ± 0.0050 | ±0.0100 | ± 0.0050 |

| Dhammaadka dusha sare | Dabacsan | Celcelis ahaan | Qalafsan |

| Xawaaraha dhis | Celcelis ahaan | Degdeg ah | Aayar |

| Codsiyada | Foomka/Tijaabinta ku haboon, Tijaabada shaqaynaysa, Qaababka qalabaynta degdega ah, Ku haboon snap, qaybo aad u faahfaahsan, moodooyinka soo bandhigida, Codsiyada kulaylka sare | Imtixaanka foom/ku haboon, Tijaabada shaqaynaysa, Qaababka qalabaynta degdega ah, Qaybo tafatiran oo yar, Qaybo leh qalab-ku-qabsasho & cidhifyada nolosha, Codsiyada kulaylka sarreeya | Imtixaanka foom/ku habboonaanta, Tijaabada shaqaynaysa, Qaababka qalabaynta degdega ah, Qaybo yar oo faahfaahsan, Moodooyinka soo bandhigida, Codsiyada bukaanka iyo cuntada, Codsiyada kulaylka sare |

Faa'iidada SLA

Stereolithography waa dhakhso

Stereolithography waa sax

Stereolithography waxay ku shaqeysaa walxo kala duwan

Waarta

Shirarka Qaybaha Badan Waa Macquul

Qoraalku waa suurtogal