Adeegga Farsamaynta Birta xaashida Gaarka ah

Astaamo

Taageerada injineernimada

Kooxda injineernimada ayaa wadaagi doona khibradooda, ka caawin doona hagaajinta naqshadaynta qayb, hubinta GD&T, xulashada agabka. Dammaanad qaad suurtogalnimada iyo tayada alaabta

Gaadhida Degdega ah

In ka badan 5000+ walxo guud oo kayd ah, 40+ mashiino si ay u taageeraan baahidaada degdegga ah ee weyn. Tusaalaha keenista in ka yar hal maalin

Aqbal naqshadaynta kakan

Waxaan haynaa goynta laser-ka ugu sarreeya, foorarsiga, alxanka iswada iyo goobaha kormeerka. Kaas oo u oggolaanaya naqshadaynta alaabta adag, shuruudda saxda ah ee sare

Guriga 2aad

Dahaarka budada ah ee midabada iyo dhalaalka kala duwan, suufka daabacaadda / shaashadda iyo shaabada kulul ee Marks, jeexjeexa iyo alxanka xitaa sanduuqa dhisa

Faa'iidooyinka birta xaashida FCE

Warshadeenu waxay ku qalabaysan tahay qalabka tignoolajiyada hogaaminaya ee wax-soo-saarka biraha. Goynta laser magdhawga firfircoon, mashiinada saarista cidhif fiiqan, mashiinada foorarsiga ee CNC saxda ah. La dammaanad qaaday dulqaadka wax-soo-saarka ugu fiican.

Dulqaad adag waa la aqbalay

FCE waxay tijaabisay oo dejisay saldhigga xogta cabbirka goynta laysarka gudaha ee agabka faraqa. Waxaan samayn karnaa saxnaanta wax soo saarka ugu fiican ee wax soo saarka ugu horreeya.

| US | Metric | |

| Laaciyo | +/- 0.5 darajo | +/- 0.5 darajo |

| Deminta | +/- 0.006 inji | +/- 0.152mm |

| Dhexroorka dalool | +/- 0.003 inji | +/- 0.063mm |

| Cidhifka ilaa cidhifka/daloolka; dalool god | +/- 0.003 inji | +/- 0. 063mm |

| Hardware ilaa gees/dalool | +/- 0.005 inji | +/- 0.127mm |

| Hardware ilaa hardware | +/- 0.007 inji | +/- 0.191mm |

| Laab gees ilaa gees | +/- 0.005 inji | +/- 0.127mm |

| U laab godka/qalabka/qallooci | +/- 0.007 inji | +/- 0.191mm |

gees af leh waa la saaray

Adiga iyo kulliyadahaaga waxaa laga yaabaa in mar walba ay ku dhaawacmaan cidhifka fiiqan ee birta. Dhanka ay dadku had iyo jeer taabtaan, FCE waxay ku siinaysaa badeecooyin laga saaray gees fiiqan.

Nadiifi oo aan xoqin

Badeecada loo baahan yahay ee qurxinta sare, waxaanu ilaalinaa dusha sare ee filimada ku dhejinaya dhammaan habka, ka saar marka ugu dambeyntii xirto alaabta.

Habka birta xaashida

Goynta laser isku dhafan ee FCE, foorarsiga CNC, feedhista CNC, alxanka, riveting iyo habka qurxinta dusha sare ee hal aqoon-is-weydaarsi. Waxaad heli kartaa badeeco dhamaystiran oo leh tayo sare iyo waqti aad u gaaban.

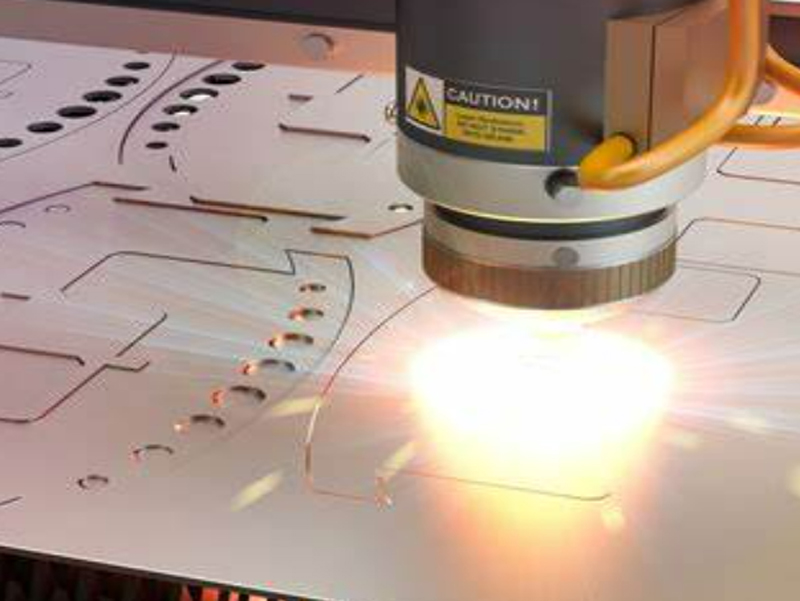

Goynta laser

Cabirka ugu badan: Ilaa 4000 x 6000 mm

Dhumucda ugu badan: Ilaa 50 mm

Ku celcelinta: +/- 0.02 mm

Saxnaanta booska: +/- 0.05 mm

foorarsan

Awoodda: Ilaa 200 oo tan

Dhererka ugu badan: Ilaa 4000 mm

Dhumucda ugu badan: Ilaa 20 mm

CNC feedh

Cabbirka farsamaynta ugu badan: 5000*1250mm

Dhumucda ugu badan: 8.35 mm

Dhererka ugu sarreeya: 88.9 mm

Riveting

Cabirka ugu badan: Ilaa 4000 x 6000 mm

Dhumucda ugu badan: Ilaa 50 mm

Ku celcelinta: +/- 0.02 mm

Saxnaanta booska: +/- 0.05 mm

Shaabadeynta

Qulqulka: 50 ~ 300 Ton

Cabbirka qaybta ugu badan: 880 mm x 400 mm

alxanka

Nooca alxanka: Arc, Laser, Resistance

Hawlgalka: Manual iyo Automation

Qalabka la heli karo ee samaynta biraha xaashida ah

FCE waxay diyaarisay 1000+ walxo xaashi wadaag ah oo kayd ah oo loogu talagalay wareejinta ugu dhaqsaha badan, injineernimadayada makaanikada ayaa kaa caawin doonta xulashada agabka, falanqaynta farsamada, hagaajinta suurtagalnimada

| Aluminium | Copper | Bronze | Birta |

| Aluminium 5052 | Copper 101 | Bronze 220 | Biraha Aan Lahayn 301 |

| Aluminium 6061 | Copper 260 (Naxaas) | Bronze 510 | Biraha Aan Lahayn 304 |

| Copper C110 | Birta aan Lahayn 316/316L | ||

| Bir, Carbon Low |

Dusha sare ayaa dhammaatay

FCE waxay bixisaa noocyo badan oo hababka daaweynta dusha sare ah. Electroplating, daahan budada ah, anodizing waa la beddeli karaa iyadoo loo eegayo midabka, texture iyo dhalaalka. Dhammaadka ku habboon ayaa sidoo kale lagu talin karaa iyadoo loo eegayo shuruudaha shaqada.

cadayashada

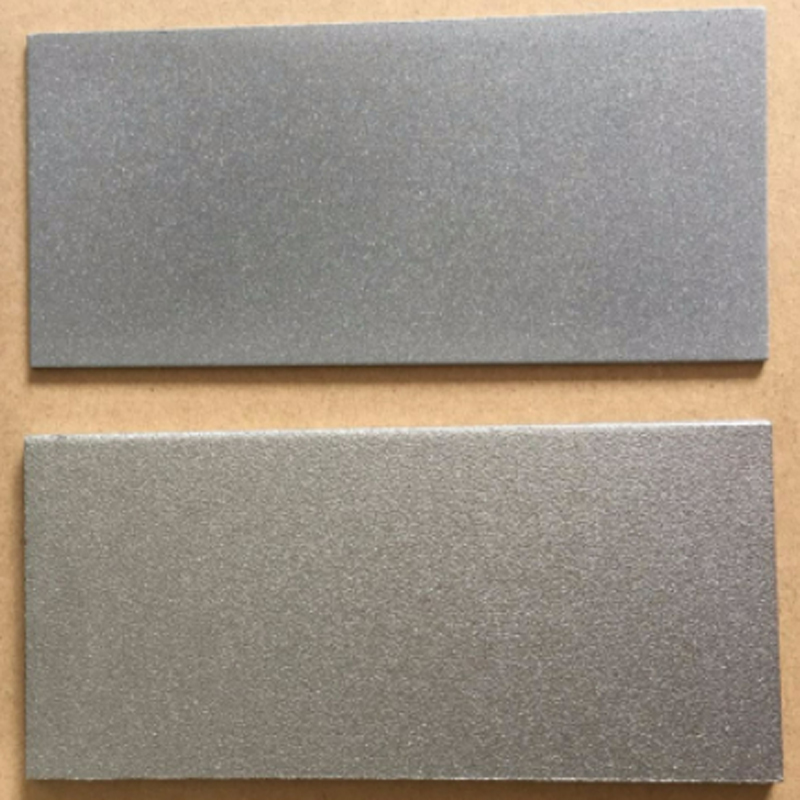

Qarax

shaandhaynta

Anodizing

Dahaarka budada

Wareejinta kulul

Duubista

Daabacaadda & Calaamadaha Laser-ka

Ballanqaadka Tayada

Su'aalaha guud

Waa maxay Biraha Sheet?

Samaynta biraha xaashida waa hab-soo-saar kala-jarid ah oo gooya ama/iyo samaysta qaybo bir ah. Qaybaha biraha xaashida ah ayaa inta badan loo isticmaali jiray saxnaanta sare iyo shuruudaha adkeysiga, codsiyada caadiga ah waa shasis, xirid, iyo xirmo.

Waa maxay Samaynta Sheet Metal?

Nidaamyada samaynta biraha xaashida waa kuwa xoogga lagu dhejiyo biraha birta si loo beddelo qaabkeeda halkii laga saari lahaa wax kasta. Awoodda la dabaqay ayaa culayska saarta birta in ka badan awoodeeda wax-soo-saarka, taasoo keenaysa in walxuhu si caag ah u beddelmaan, laakiin ma jabaan. Ka dib markii xoogga la sii daayo, xaashida ayaa dib u soo noqon doonta wax yar, laakiin asal ahaan qaababka sida loo riixo.

Waa maxay shaabadaynta birta?

Si loo kordhiyo waxtarka wax soo saarka biraha, biraha stamping die waxaa loo isticmaalaa in lagu beddelo biraha fidsan qaabab gaar ah. Waa hab-socod adag oo ay ku jiri karaan tiro farsamooyin bir-abuur ah - faaruqin, feedh, foorarsi iyo daloolid.

Waa maxay muddada lacag bixinta?

Macmiil cusub, 30% lacag-bixin hore. Isku dheellitir inta soo hartay ka hor intaadan rarin alaabta. Amarka caadiga ah, waxaanu aqbalnaa muddo saddex bilood ah oo biilasha ah