Ku calaamadinta caaryada

Habka la heli karo Mashiinka CNC

Khibrada Injineerinka iyo Hagidda

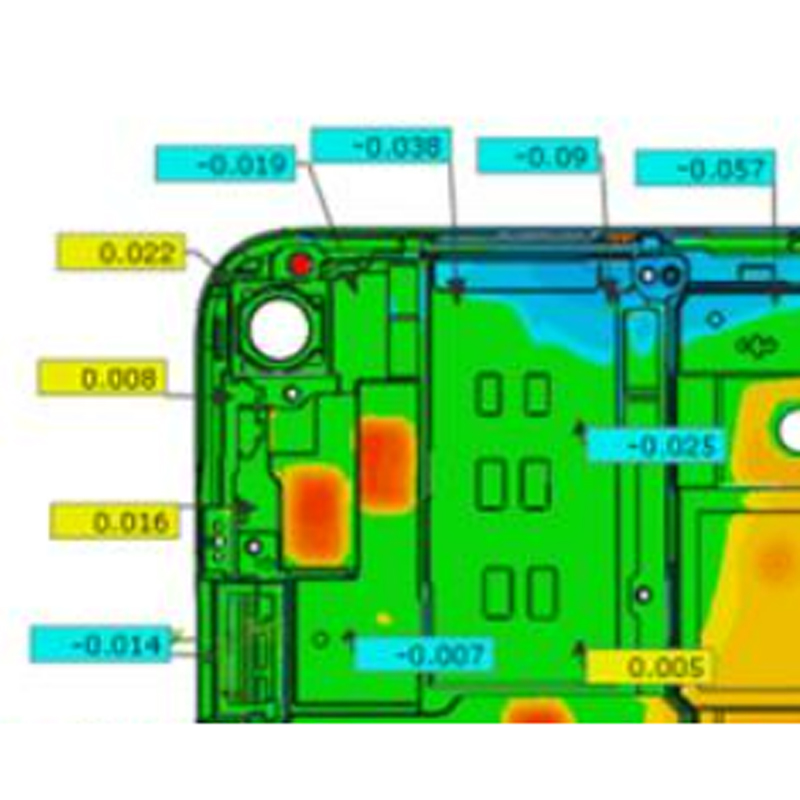

Kooxda Injineerinka ayaa kaa caawin doona sidii aad u wanaaji lahayd nashqadeynta qaybta naqshadaynta, hubinta GD&T, xulashada agabka. 100% hubi badeecada leh suurtogalnimada wax soo saarka sare, tayada, raadinta

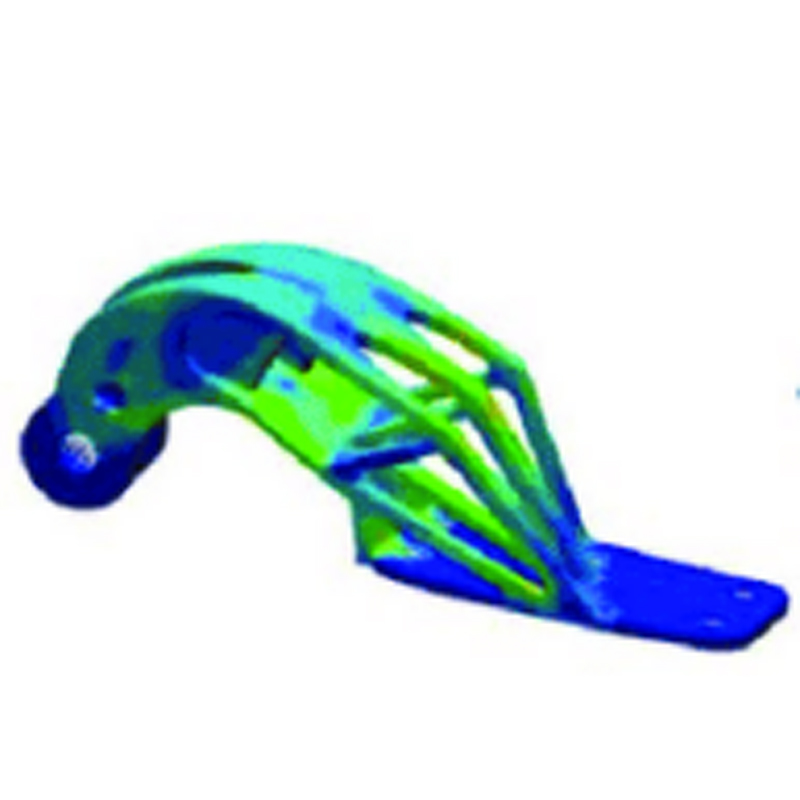

Jilidda ka hor inta aan la jarin Birta

Saadaasha kasta, waxaan u isticmaali doonaa qulqulka caaryada, Creo, Mastercam si aan u ekayno habka qaabaynta duritaanka, habka mashiinada, habka sawirista si loo saadaaliyo arrinta ka hor inta aan la samayn muunado jireed

Naqshadaynta Alaabta Kakan waa la aqbalay

Waxaan haynaa tas-hiilaadka wax soo saarka summada ugu sarreeya ee naqshadaynta duritaanka, mashiinnada CNC iyo samaynta biraha xaashida ah. Kaas oo u oggolaanaya naqshadaynta alaabta adag, shuruudda saxda ah ee sare

Habka guriga

Samaynta caaryada duritaanka, qaabaynta cirbadaha iyo habka labaad ee daabacaadda suufka, kulaylka, stamping kulul, isu imaatinka dhamaantood waxay ku yaalaan guriga, markaa waxaad yeelan doontaa qiimo jaban iyo waqti horumarineed oo la isku halayn karo

Ku calaamadinta caaryada

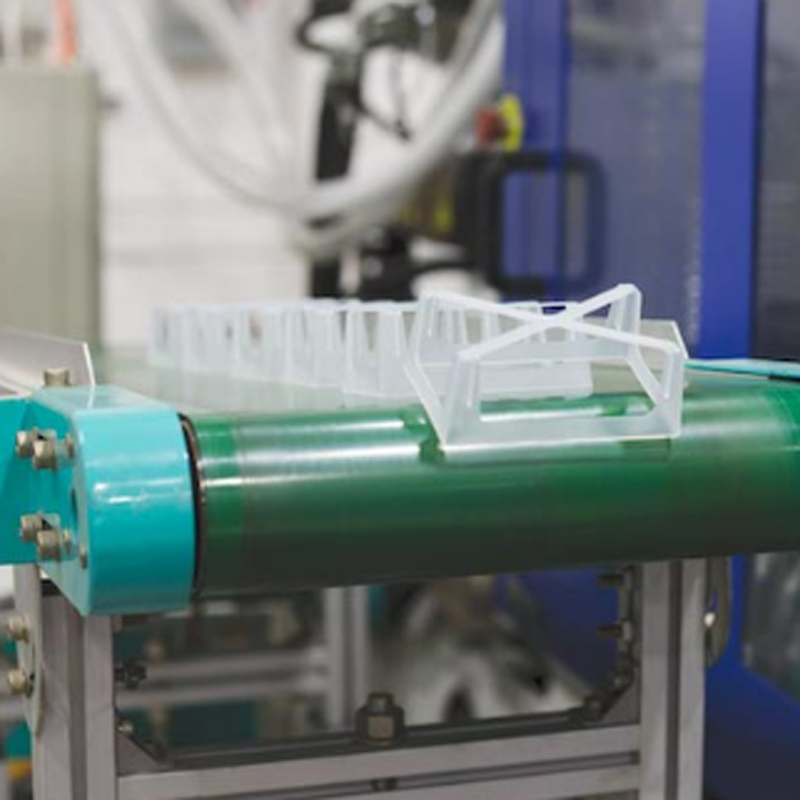

In caaryada calaamadaynta (IML) waa hab irbaynta qaabaynta kaas oo qurxinta qaybta balaastikada, iyadoo la adeegsanayo calaamad, lagu soo saaro habka duritaanka balaastikada. Si fudud loo dhigo, calaamad hore loo daabacay ayaa la geliyaa iyada oo loo marayo otomaatig ah godka caaryada duritaanka iyo caag ayaa lagu duraa calaamadda. Tani waxay soo saartaa qayb balaastig ah oo la qurxiyey/"la sumadeeyey" taaso summadadu si joogto ah ugu dheggan tahay qaybta lafteeda

Faa'iidooyinka Rosti farsamooyinka calaamadaynta caaryada waxaa ka mid ah:

• Ilaa 45% qalooca foornada (dhererka ilaa ballaca)

Habka xorta ah ee qallalan oo dareere ah

• Awoodda naqshadaynta aan xadidnayn

• Isbedelka naqshadeynta degdega ah

• Sawirro heer sare ah

• Qiime jaban, gaar ahaan mashaariicda mugga sare leh

• In aan teknoolojiyada kale lagu gaari karin saameyn aan suurtagal ahayn

• Ku adag oo u adag kaydinta nadaafadda ee alaabta la qaboojiyey iyo talaajadyada

• Dhammaadka u adkaysta waxyeelada

• Deegaanka oo miyir qaba

Faa'iidooyinka IML

Qaar ka mid ah faa'iidooyinka farsamada ee IML waxaa ka mid ah:

• Qurxinta dhamaystiran ee qaybta la qaabeeyey

• Waarta garaafyada: Khadadka waxaa lagu ilaaliyaa filim marka la dhisayo dusha labaad

• Hawlgallada labaad ee la xidhiidha qurxinta wax-ku-samaynta ka dib waa la tirtiray

• Baabi'inta baahida aagagga summada ee dib loo furay

• Filimo badan iyo dhismayaal la heli karo si loo buuxiyo shuruudaha macaamiisha

• Si fudud loo soo saaro codsiyo midabyo badan leh

• Guud ahaan hoos u dhaca heerarka qashinka

• Aad u adkeysi badan oo aan faragelin lahayn

• Isku dheelitirka midabka sare

• Ma jirto meel ay wasakhdu ku ururin karto

• Midabo aan xadidnayn ayaa la heli karaa

Codsiga Calaamadaynta Caaryada

Aad ayey ugu xiran tahay male-awaalkaaga inaad go'aansato mashaariicda isticmaali kara calaamadaynta caaryada, laakiin halkan waxaa ah mashaariic socda iyo kuwo soo socda;

- filtarrada tumbler qalalan, si otomaatig ah loogu sameeyo habka quudinta

- calaamadaynta saliingadaha iyo fijaanadaha

- calaamadaynta iyo calaamadaynta qaybaha warshadaha baabuurta

- shakhsiyaynta alaabta warshadaha dawooyinka iwm

- raadraaca alaabooyinka leh RFID

- qurxinta alaabta aan caadiga ahayn sida dunta

Liiska waxa la samayn karaa wakhti dheer mustaqbalkana waxa uu muujin doonaa cusub oo aan wali la maqal codsiyo ka dhigaya wax soo saarka mid jaban oo degdega, wanaajiya tayada iyo hagaajinta badbaadada, raadinta iyo qaybinta

Qalabka Calaamadeynta Caaryada

Ku dheggan ee u dhexeeya foils kala duwan iyo agabka wax-samaynta

| Qalab xad dhaaf ah | |||||||||||||||||

| ABS | ASA | EVA | PA6 | PA66 | PBT | PC | PEHD | PELD | PET | PMMA | POM | PP | PS-HI | SAN | TPU | ||

| Walxaha foil | ABS | ++ | + | + | + | + | - | - | + | + | - | - | ∗ | + | + | ||

| ASA | + | ++ | + | + | + | - | - | + | + | - | - | - | + | + | |||

| EVA | + | + | ++ | + | + | + | + | + | |||||||||

| PA6 | ++ | + | ∗ | ∗ | ∗ | ∗ | - | ∗ | - | + | + | ||||||

| PA66 | + | ++ | ∗ | ∗ | ∗ | ∗ | - | - | - | + | + | ||||||

| PBT | + | + | ∗ | ∗ | ++ | + | - | - | + | - | - | - | - | + | + | ||

| PC | + | + | ∗ | ∗ | + | ++ | - | - | + | + | - | - | - | + | + | ||

| PEHD | - | - | + | ∗ | ∗ | - | - | ++ | + | - | ∗ | ∗ | - | - | - | - | |

| PELD | - | - | + | ∗ | ∗ | - | - | + | ++ | - | ∗ | ∗ | + | - | - | - | |

| PET | + | + | + | + | - | - | + | - | - | - | + | ||||||

| PMMA | + | + | - | - | ∗ | ∗ | - | ++ | ∗ | - | + | ||||||

| POM | - | - | - | - | - | - | ∗ | ∗ | - | ++ | - | - | - | ||||

| PP | - | - | + | ∗ | - | - | - | - | + | ∗ | - | ++ | - | - | - | ||

| PS-HI | ∗ | - | + | - | - | - | - | - | - | - | - | - | - | ++ | - | - | |

| SAN | + | + | + | + | + | + | + | - | - | + | - | - | - | ++ | + | ||

| TPU | + | + | + | + | + | + | - | - | + | - | - | + | + | ||||

++ Xabag aad u wanaagsan, + Ku dheggan wanaagsan,

EVA, Ethylene vinyl acetate; PA6, Polyamide 6; PA66, Polyamide 66; PBT, terephthalate polybutylene; PEHD, cufnaanta sare ee Polyethylene; PELD, Polyethylene cufnaanta hoose; POM, Polyoxymethylene; PS-HI, Saamaynta Sare ee Polystyrene; SAN, Styrene Acrylonitrile; TPU, polyurethane Thermoplastic.

Awoodaha qaraabo ee IML vs. IMD calaamadaynta xalalka

Isku-darka habka qurxinta iyo habka wax-soo-saarka waxay ku kordhinaysaa adkeysiga, waxay yareysaa kharashka wax soo saarka waxayna abuurtaa dabacsanaanta naqshadeynta.

Waarta

Sawiradu waa wax aan suurtagal ahayn in la saaro iyada oo aan la burburin qaybta caaga ah waxayna ahaan doontaa mid firfircoon nolosha qaybta. Ikhtiyaarada ayaa diyaar u ah adkeysiga la xoojiyey ee jawiga adag iyo caabbinta kiimikada.

Waxtarka-kharashka

IML waxay tirtirtaa calaamadaynta, maaraynta iyo kaydinta ka dib qaabaynta. Waxay yaraynaysaa alaabada WIP iyo wakhtiga dheeraadka ah ee loo baahan yahay qurxinta wax-soo-saarka kadib, goobta- ama bannaanka.

Dabacsanaanta naqshadeynta

IML waxaa lagu heli karaa noocyo kala duwan oo midabo, saameyn, textures iyo fursadaha garaafyada oo soo celin karaa xitaa kuwa ugu adag sida birta ahama, badar alwaax iyo fiber carbon. Marka shahaado UL loo baahdo, muunado summadaha caaryada ku jira ayaa la qiimeeyaa iyadoo la raacayo isla heerarka badbaadada ee loo isticmaalo in lagu qiimeeyo calaamadaha xasaasiga ah.