Special Price for Metal Insert Molding - Custom Sheet Metal Fabrication Service – FCE Detail:

Icons

Engineering support

Engineering team will share their experience, assist on part design optimization, GD&T check, material selection. Guarantee the product feasibility and quality

Fast Delivery

More than 5000+ common material in stock, 40+ machines to support your large the urgent demand. Sample delivery as few as one day

Accept Complex design

We have the top brand laser cutting, bending, auto-welding and inspection facilities. Which allows complex, high precision requirement product design

In house 2nd process

Powder coating for different color and brightness, Pad/screen printing and hot stamping for Marks, riveting and welding even box build assembly

Advantages of FCE Sheet metal

Our factory equipped leading technology equipment of sheet metal fabrications. Dynamic compensation laser cutting, auto sharp edge removing machines, precision CNC bending machines. Guaranteed the best manufacture tolerance.

Tight Tolerance Accepted

FCE tested and set up internal laser cutting parameter data base for difference materials. We can make the best manufacturing accuracy on the first production.

| US | Metric | |

| Bends | +/- 0.5 degree | +/- 0.5 degree |

| Offsets | +/- 0.006 in. | +/- 0.152mm |

| Hole Diameters | +/- 0.003 in. | +/- 0.063mm |

| Edge to edge/hole; hole to hole | +/- 0.003 in. | +/- 0. 063mm |

| Hardware to edge/hole | +/- 0.005 in. | +/- 0.127mm |

| Hardware to hardware | +/- 0.007 in. | +/- 0.191mm |

| Bend to edge | +/- 0.005 in. | +/- 0.127mm |

| Bend to hole/hardware/bend | +/- 0.007 in. | +/- 0.191mm |

Sharp edge removed

You and your colleges may always be hurt by the sharp edge of sheet metal. For the part people always touch, FCE offer fully sharp edge removed products for you.

Clean and free of scratch

For high cosmetic requirement product, we protect the surface with attaching films for all of the process, peel it off when finally pack the product.

Sheet Metal Process

FCE integrated laser cutting, CNC bending, CNC punching, welding, riveting and surface decoration process in one workshop. You can get complete product with high quality and very short lead time.

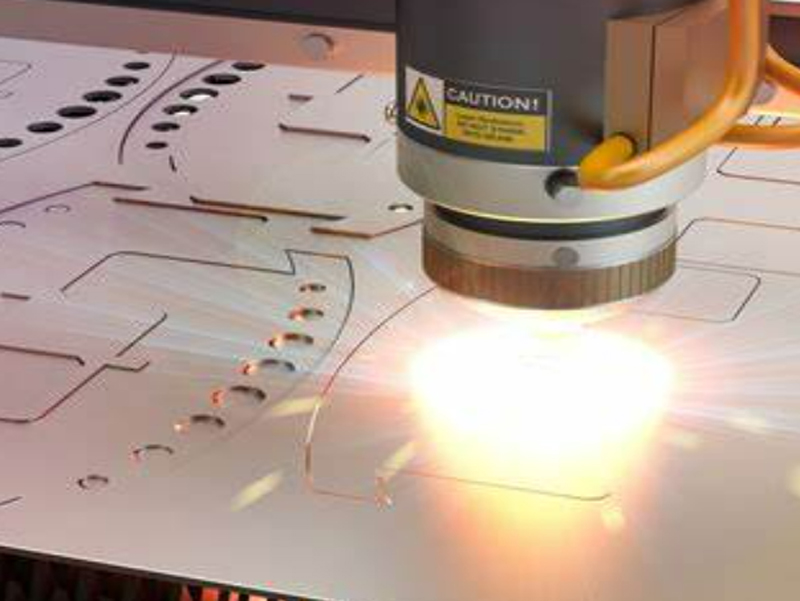

Laser cutting

Max Size: Up to 4000 x 6000 mm

Max Thickness: Up to 50 mm

Repeatability: +/- 0.02 mm

Position accuracy: +/- 0.05 mm

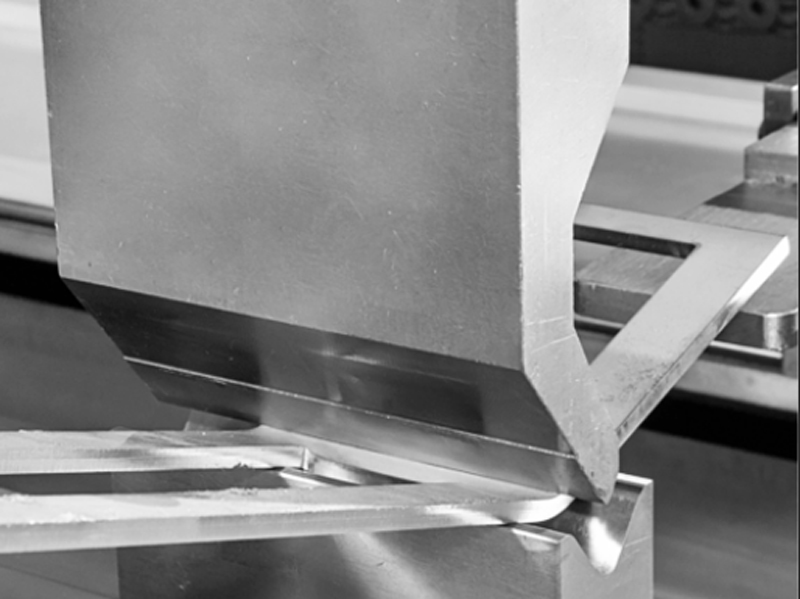

Bending

Capacity: Up to 200 tons

Max Length: Up to 4000 mm

Max Thickness: Up to 20 mm

CNC punching

Max processing size: 5000*1250mm

Max thickness: 8.35 mm

Max punching dia: 88.9 mm

Riveting

Max Size: Up to 4000 x 6000 mm

Max Thickness: Up to 50 mm

Repeatability: +/- 0.02 mm

Position accuracy: +/- 0.05 mm

Stamping

Tonnage: 50~300 Ton

Max part size: 880 mm x 400 mm

Welding

Welding type: Arc, Laser, Resistance

Operation: Manual and Automation

Available Materials for sheet metal fabrication

FCE prepared 1000+ common sheet material in stock for fastest turnaround, Our mechanical engineering will help you on material selection, mechanical analysis, feasibility optimizations

| Aluminum | Copper | Bronze | Steel |

| Aluminum 5052 | Copper 101 | Bronze 220 | Stainless Steel 301 |

| Aluminum 6061 | Copper 260 (Brass) | Bronze 510 | Stainless Steel 304 |

| Copper C110 | Stainless Steel 316/316L | ||

| Steel, Low Carbon |

Surface Finishes

FCE offers a complete range of surface treatment processes. Electroplating, powder coating, anodizing can be customized according to color, texture and brightness. The appropriate finish can also be recommended according to functional requirements.

Brushing

Blasting

Polishing

Anodizing

Powder Coating

Hot Transfer

Plating

Printing & Laser Mark

Our Quality Promise

General FAQs

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a subtractive manufacturing process that cuts or/and forms parts by metal sheets. Sheet metal parts were often used for the high precision and durability requirement, typical applications are chassis, enclosures, and brackets.

What is Sheet Metal Forming?

Sheet metal forming processes are those in which force is applied to sheet metal to modify its shape rather than remove any material. The applied force stresses the metal beyond its yield strength, causing the material to plastically deform, but not to break. After the force released, the sheet will spring back a little, but basically keep the shapes as pressed.

What is metal stamping?

To increase the sheet metal manufacturing efficiency, Metal stamping die is used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing.

What is the payment term?

New customer, 30% pre-pay. Balance the rest before ship the product. Regular order, we accept Three-month billing period

Product detail pictures:

Related Product Guide:

Our firm promises all consumers with the first-class products as well as most satisfying post-sale services. We warmly welcome our regular and new consumers to join us for Special Price for Metal Insert Molding - Custom Sheet Metal Fabrication Service – FCE , The product will supply to all over the world, such as: Oman, Jersey, luzern, Our product quality is one of the major concerns and has been produced to meet the customer's standards. Customer services and relationship is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.