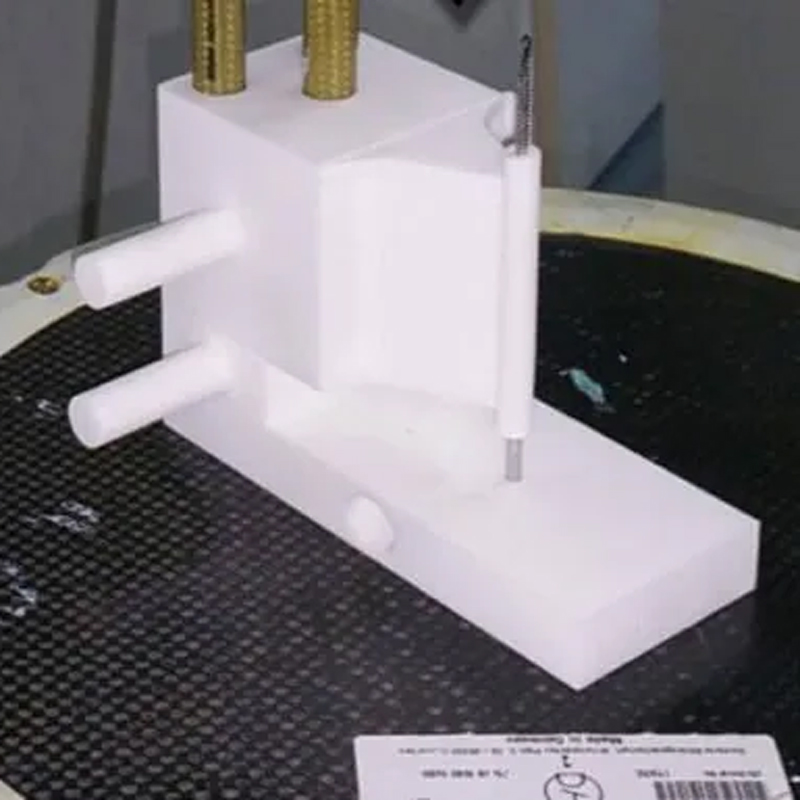

SLA

Tataiso ea Moralo oa SLA

Qeto ea ho hatisa

Botenya bo tloaelehileng ba lera: 100 µm Ho nepahala: ±0.2% (ka moeli o tlase oa ± 0.2 mm)

Tekanyo ea boholo 144 x 144 x 174 mm Botenya bo tlase Botenya ba lebota bo tlase 0.8mm - Ka karolelano ea 1:6

Etching le Embossing

Bonyane bo bolelele le bophara ba lintlha tse hatisitsoeng: 0.5 mm

E ngotsoe: 0.5 mm

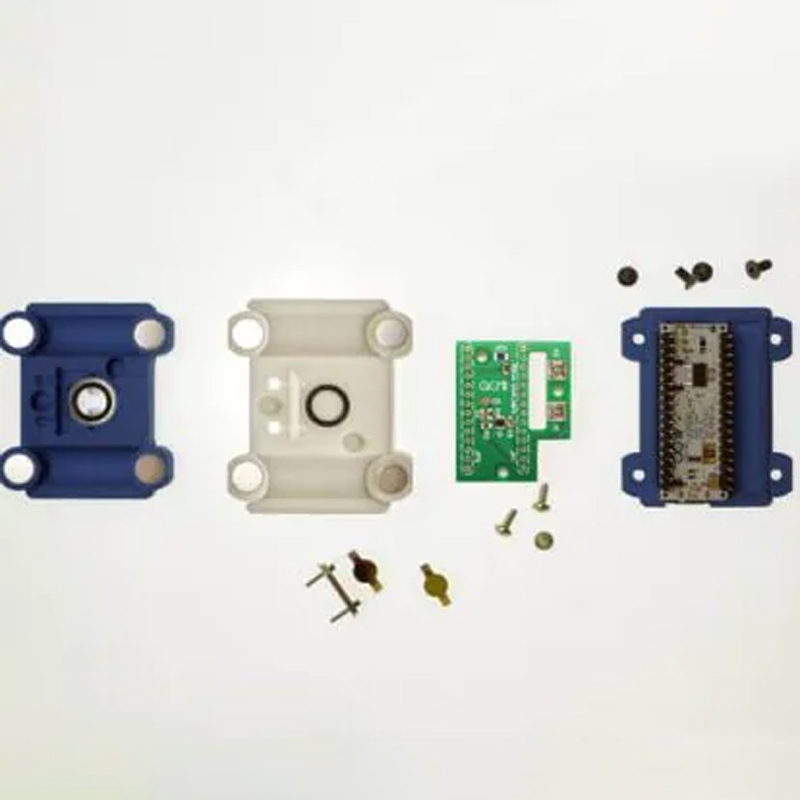

Bolumo e kentsoeng le e hokahaneng

Likarolo tse kentsoeng? Ha e khothalletsoe likarolo tsa Interlocking? Ha e khothalletsoe

Thibelo ea kopano ea likotoana

Kopano? Che

Tsebo ea Boenjiniere le Tataiso

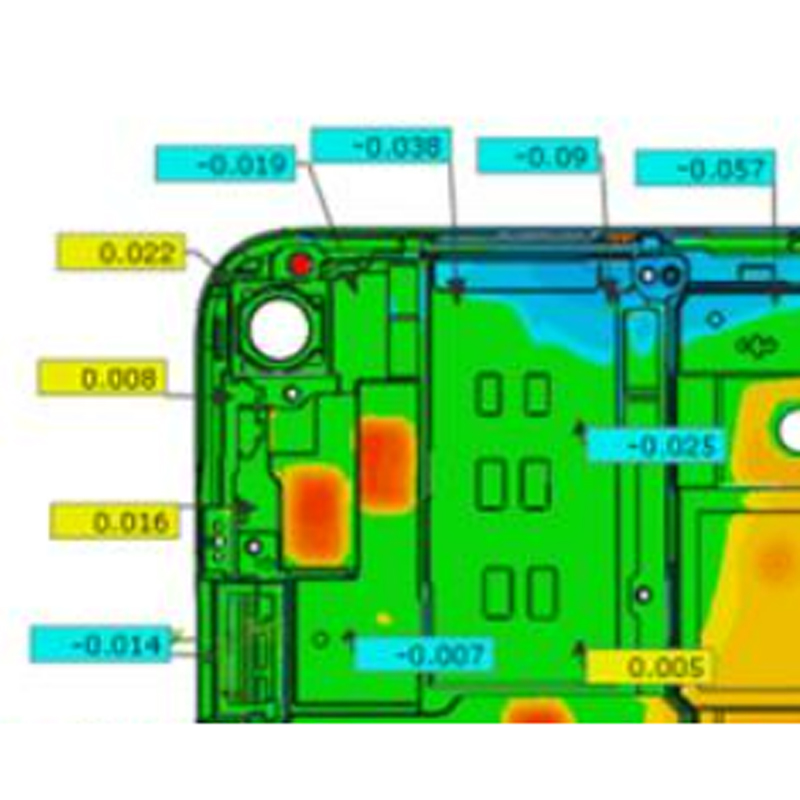

Sehlopha sa boenjiniere se tla u thusa ho ntlafatsa moralo oa karolo ea ho bopa, tlhahlobo ea GD&T, khetho ea thepa. 100% netefatsa hore sehlahisoa se na le bokhoni bo phahameng ba tlhahiso, boleng, traceability

Ketsiso pele ho Cutting Steel

Bakeng sa khakanyo e 'ngoe le e' ngoe, re tla sebelisa mold-flow, Creo, Mastercam ho etsisa mokhoa oa ho bopa ente, ts'ebetso ea machining, mokhoa oa ho taka ho bolela esale pele taba pele u etsa lisampole tsa 'mele.

Moqapi oa Sehlahisoa o Ratang

Re na le lisebelisoa tse holimo tsa tlhahiso ea lihlahisoa tsa ho etsa ente, mochini oa CNC le masela a tšepe. E lumellang moralo oa sehlahisoa o rarahaneng, o nepahetseng haholo o hlokahalang

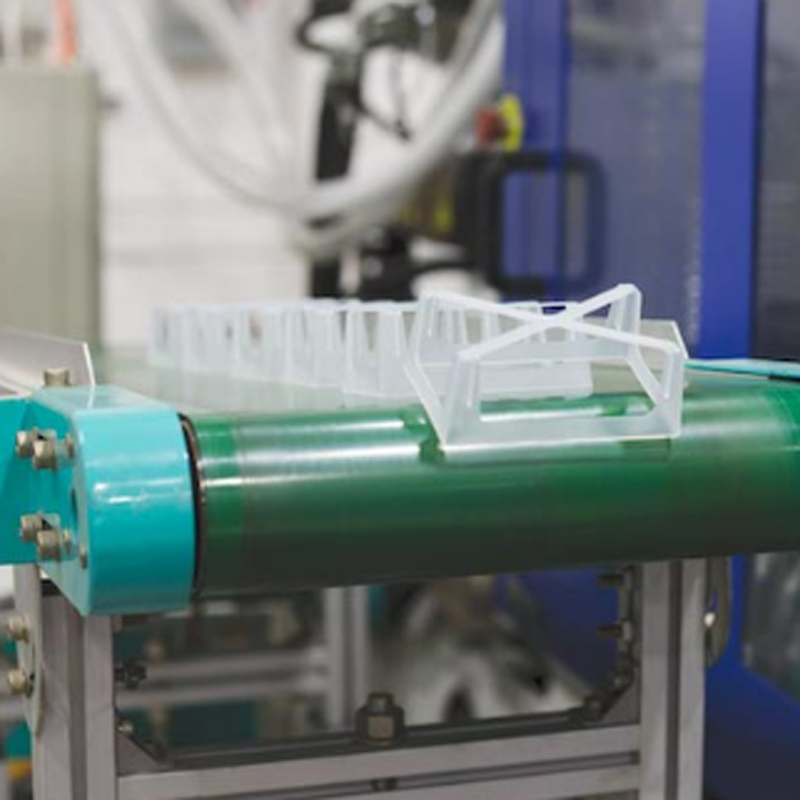

Ts'ebetsong ea ntlo

Ho etsa hlobo ea ente, mochini oa ente le ts'ebetso ea bobeli ea khatiso ea pad, staking ea mocheso, setempe se chesang, kopano kaofela li ka tlung, kahoo o tla ba le litšenyehelo tse tlase haholo le nako e tšepahalang ea nts'etsopele.

Melemo ea Khatiso ea SLA

Lintlha tse phahameng tsa boemo

Haeba o hloka ho nepahala, SLA ke ts'ebetso ea tlatsetso eo u e hlokang ho theha li-prototypes tse qaqileng haholo.

Lisebelisoa tse fapaneng

Ho tloha ho likoloi ho ea ho lihlahisoa tsa bareki, lik'hamphani tse ngata li sebelisa Stereolithography bakeng sa prototyping e potlakileng

Tokoloho ea moralo

Tlhahiso e entsoeng ka moralo e u lumella ho hlahisa li-geometri tse rarahaneng

Sesebelisoa sa SLA

Tsa makoloi

Tlhokomelo ea Bophelo le Bongaka

Mechini

High tech

Thepa ea indasteri

Tsa elektroniki

SLA vs SLS vs FDM

| Lebitso la Thepa | Stereolithography | Khetho ea Laser Sintering | Fused Deposition Modeling |

| Kgutsufatso | SLA | SLS | FDM |

| Mofuta oa thepa | Mokelikeli (Photopolymer) | Phofo (Polymer) | Tiileng (Likhoele) |

| Lisebelisoa | Thermoplastics (Elastomers) | Thermoplastics tse kang Nylon, Polyamide, le Polystyrene; Lielastomer; Likopano | Thermoplastics tse kang ABS, Polycarbonate, le Polyphenylsulfone; Li-elastomers |

| Boholo ba karolo ea boholo (ka.) | 59.00 x 29.50 x 19.70 | 22.00 x 22.00 x 30.00 | 36.00 x 24.00 x 36.00 |

| Boholo bo fokolang ba karolo (ka.) | 0.004 | 0.005 | 0.005 |

| Min layer thick (in.) | 0.0010 | 0.0040 | 0.0050 |

| Mamello (in.) | ±0.0050 | ±0.0100 | ±0.0050 |

| Qetello ea bokaholimo | Boreleli | Karolelano | E kgohlahetseng |

| Haha lebelo | Karolelano | Ka potlako | Butle |

| Lisebelisoa | Teko ea liforomo/ho lekana, Teko ea tšebetso, Mekhoa ea ho sebetsa ka potlako, li-snap fit, Likarolo tse qaqileng haholo, Mehlala ea tlhahiso, Lisebelisoa tsa mocheso o phahameng | Teko ea liforomo/ho lekana, Teko ea tšebetso, Mekhoa e potlakileng ea lisebelisoa, Likarolo tse sa qaqisoang haholo, Likarolo tse nang le li-snap-fits & hinges tse phelang, Lisebelisoa tsa mocheso o phahameng | Teko ea liforomo/ho lekana, Teko ea tšebetso, Mekhoa ea ho sebetsa ka potlako, Likarolo tse nyane tse qaqileng, Mehlala ea nehelano, Lisebelisoa tsa mokuli le lijo, Lits'ebetso tse phahameng tsa mocheso. |

SLA Molemo

Stereolithography e Potlakile

Stereolithography e Nepahetse

Stereolithography e sebetsa ka lisebelisoa tse fapaneng

Moshoelella

Likopano tse nang le likarolo tse ngata lia khoneha

Ho Kopana ka Sengoloa hoa Khoneha