Custom Sheet Metal Fabrication Service

Litšoantšo

Tšehetso ea boenjiniere

Sehlopha sa boenjiniere se tla arolelana boiphihlelo ba bona, ho thusa molemong oa ntlafatso ea moralo, tlhahlobo ea GD&T, khetho ea thepa. Etsa bonnete ba hore sehlahisoa se khonahala le boleng

Phano e potlakileng

Ho feta 5000+ lisebelisoa tse tloaelehileng setokong, mechini e fetang 40 ho tšehetsa tlhoko ea hau e kholo e potlakileng. Mohlala oa thomello ke tse fokolang joalo ka letsatsi le le leng

Amohela moralo o rarahaneng

Re na le lisebelisoa tsa boleng bo holimo tsa laser ho itšeha, ho kobeha, ho tjheseletsa le ho hlahloba. E lumellang moralo oa sehlahisoa o rarahaneng, o nepahetseng haholo o hlokahalang

Ka tlung 2nd tshebetso

Ho roala ka phofo bakeng sa mebala e fapaneng le ho khanya, khatiso ea Pad/screen le ho hatisa setempe se chesang bakeng sa Matšoao, riveting le welding esita le lebokose la ho haha lebokose.

Melemo ea tšepe ea FCE Sheet

Feme ea rona e na le lisebelisoa tsa theknoloji tse etellang pele tsa masela a tšepe. Matla a mats'eliso a laser ho itšeha, mechini e tlosang bohale ba koloi, metjhini e kobehang ea CNC e nepahetseng. Guaranteed molemo ka ho fetisisa tlhahiso mamello.

Mamello e Matla e Amogetswe

FCE e ile ea leka le ho theha setsi sa data sa ka hare sa laser cutting parameter bakeng sa lisebelisoa tse fapaneng. Re ka etsa ho nepahala ha tlhahiso ka ho fetisisa tlhahisong ea pele.

| US | Metric | |

| Kobeha | +/- likhato tse 0.5 | +/- likhato tse 0.5 |

| Li-offsets | +/- 0.006 in. | +/- 0.152mm |

| Hole Diameters | +/- 0.003 in. | +/- 0.063mm |

| Moeli ho isa moeling / lesoba; lesoba ho lesoba | +/- 0.003 in. | +/- 0. 063mm |

| Hardware ho isa pheletsong/ lesoba | +/- 0.005 in. | +/- 0.127mm |

| Hardware ho hardware | +/- 0.007 ka hare. | +/- 0.191mm |

| Koba ho isa pheletsong | +/- 0.005 in. | +/- 0.127mm |

| Kobela ho lesoba/hardware/koba | +/- 0.007 ka hare. | +/- 0.191mm |

Ho tlositsoe lehlakore le bohale

Uena le likoleche tsa hau le ka 'na la utloisoa bohloko kamehla ke bohale bo bohale ba tšepe. Bakeng sa karolo eo batho ba e amang kamehla, FCE e fana ka lihlahisoa tse tlositsoeng ka botlalo bakeng sa hau.

E hloekile ebile ha e na mongoaha

Bakeng sa sehlahisoa se hlokahalang sa litlolo tse phahameng, re sireletsa bokaholimo ka ho hokela lifilimi bakeng sa ts'ebetso eohle, re li qolla ha qetellong re paka sehlahisoa.

Sheet Metal Process

FCE e kopantseng laser ho itšeha, ho kobeha ha CNC, ho phunya CNC, ho cheselletsa, ho riveting le mokhoa oa ho khabisa holim'a pokello ea mesebetsi e le 'ngoe. U ka fumana sehlahisoa se felletseng ka boleng bo holimo le nako e khutšoane haholo ea ho etella pele.

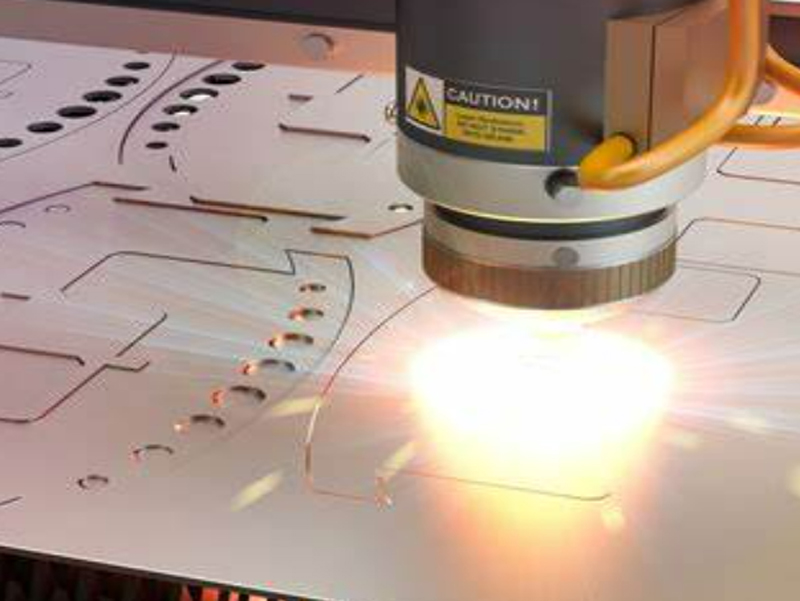

Ho itšeha ka laser

Boholo ba Boholo: Ho fihla ho 4000 x 6000 mm

Boholo ba Botenya: Ho fihlela ho 50 mm

Pheta-pheta: +/- 0.02 limilimithara

Ho nepahala ha boemo: +/- 0.05 mm

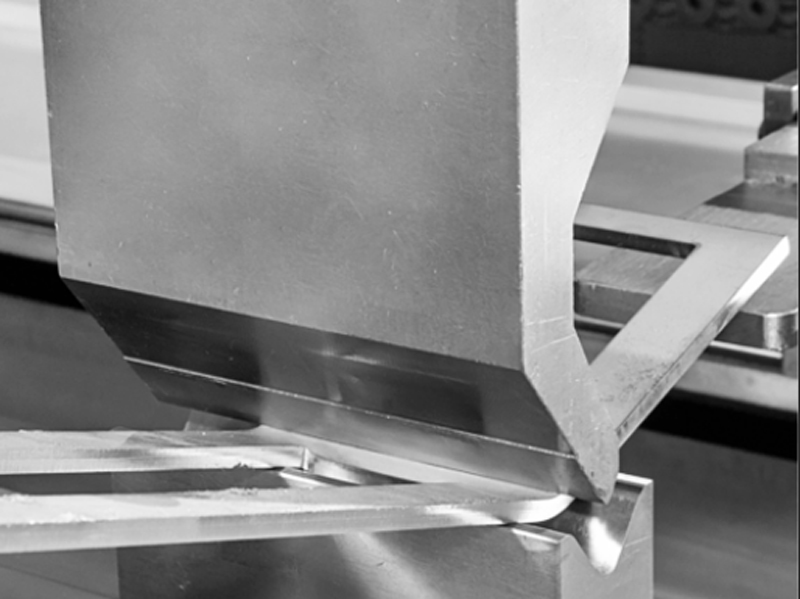

Ho kobeha

Bokhoni: Ho fihla ho lithane tse 200

Boholo Bolelele: Ho fihla ho 4000 mm

Boholo ba Botenya: Ho fihlela ho 20 mm

CNC ho otla

Boholo ba ho sebetsa: 5000 * 1250mm

Botenya bo boholo: 8.35 mm

Boholo ba ho phunya: 88.9 mm

Riveting

Boholo ba Boholo: Ho fihla ho 4000 x 6000 mm

Boholo ba Botenya: Ho fihlela ho 50 mm

Pheta-pheta: +/- 0.02 limilimithara

Ho nepahala ha boemo: +/- 0.05 mm

Ho hatakela

Tonnage: 50 ~ 300 Ton

Boholo ba karolo ea boholo: 880 mm x 400 mm

Welding

Mofuta oa welding: Arc, Laser, Resistance

Ts'ebetso: Manual le Automation

Lisebelisoa tse fumanehang bakeng sa ho etsa lesela la tšepe

FCE e lokiselitse lisebelisoa tse 1000+ tse tloaelehileng tse fumanehang setokong bakeng sa phetoho e potlakileng, Boenjiniere ba rona ba mochini bo tla u thusa khethong ea thepa, tlhahlobo ea mochini, optimizations ea ho khoneha.

| Aluminium | Koporo | Boronse | Tšepe |

| Aluminium 5052 | Koporo 101 | Boronse 220 | Sebetsa 301 |

| Aluminium 6061 | Koporo 260 (Koporo) | Bronze 510 | Sebetsa 304 |

| Koporo C110 | Tšepe e se nang Mokelikeli 316/316L | ||

| Tšepe, Khabone e Tlase |

Sebaka se Felisang

FCE e fana ka mefuta e mengata ea mekhoa ea phekolo ea holim'a metsi. Electroplating, ho roala phofo, anodizing e ka etsoa ho latela 'mala, sebopeho le khanya. Qetello e loketseng e ka boela ea buelloa ho latela litlhoko tsa ts'ebetso.

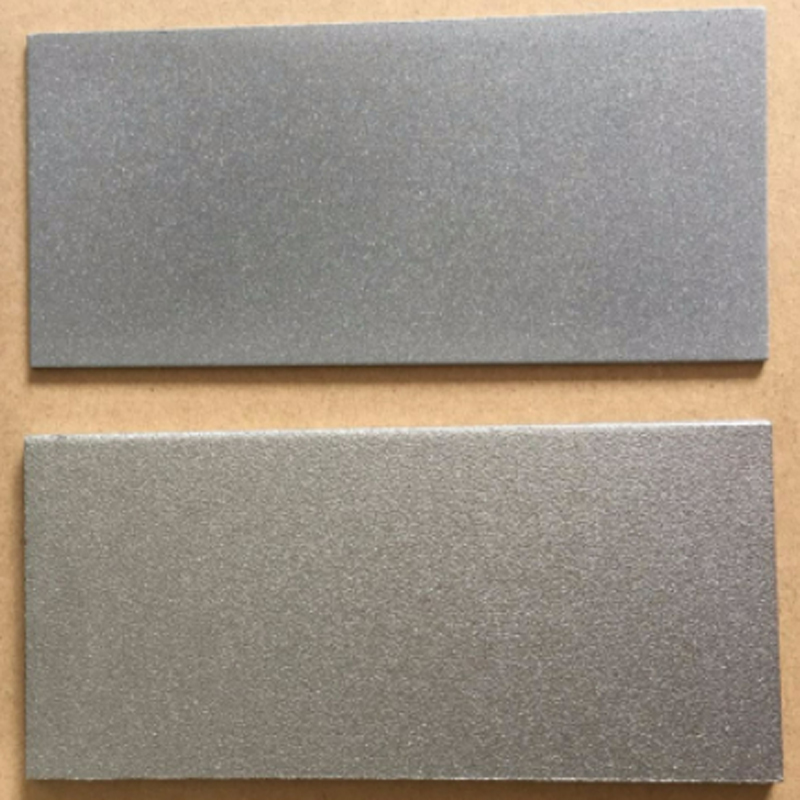

Ho roala borashe

Ho qhoma

Ho benya

Anodizing

Ho roala ka phofo

Phetisetso e Chesang

Ho roala

Khatiso & Laser Mark

Tšepiso ea rona ea Boleng

Lipotso tse akaretsang

Ho Etsa Metal Metal ke Eng?

Ho etsoa ha tšepe ea pampiri ke mokhoa oa ho etsa lintho o fokotsang kapa / le ho etsa likarolo ka lishiti tsa tšepe. Likarolo tsa tšepe tsa maqephe li ne li atisa ho sebelisoa bakeng sa tlhokahalo e phahameng ea ho nepahala le ho tšoarella, lisebelisoa tse tloaelehileng ke chassis, likoti, le masaka.

Sheet Metal Forming ke Eng?

Mekhoa ea ho etsa litšepe tsa pampiri ke tseo ho tsona ho sebelisoang matla a tšepe ho fetola sebopeho sa eona ho e-na le ho tlosa thepa leha e le efe. Matla a sebelisitsoeng a hatisa tšepe ka nģ'ane ho matla a eona a ho hlahisa, e leng se etsang hore thepa e fetohe ka polasetiki, empa e se ke ea senya. Kamora hore matla a lokolloe, letlapa le tla khutla hanyane, empa ha e le hantle boloka libopeho joalo ka ha li hatelloa.

Setempe sa tšepe ke eng?

Ho eketsa ts'ebetso ea tlhahiso ea tšepe, Metal stamping die e sebelisoa ho fetolela maqephe a tšepe a bataletseng hore e be libopeho tse ikhethileng. Ke ts'ebetso e rarahaneng e ka kenyelletsang mekhoa e mengata ea ho etsa tšepe - ho koala, ho phunya, ho koba le ho phunya.

Nako ea tefo ke efe?

Moreki e mocha, 30% e lefa pele. Leka-lekanya tse ling pele u romela sehlahisoa. Odara ea kamehla, re amohela nako ea tefiso ea likhoeli tse tharo