Tšebeletso ea Machining ea CNC

Mokhoa oa ho sebetsa oa CNC o fumanehang

Tšebeletso ea ho Milling ea CNC

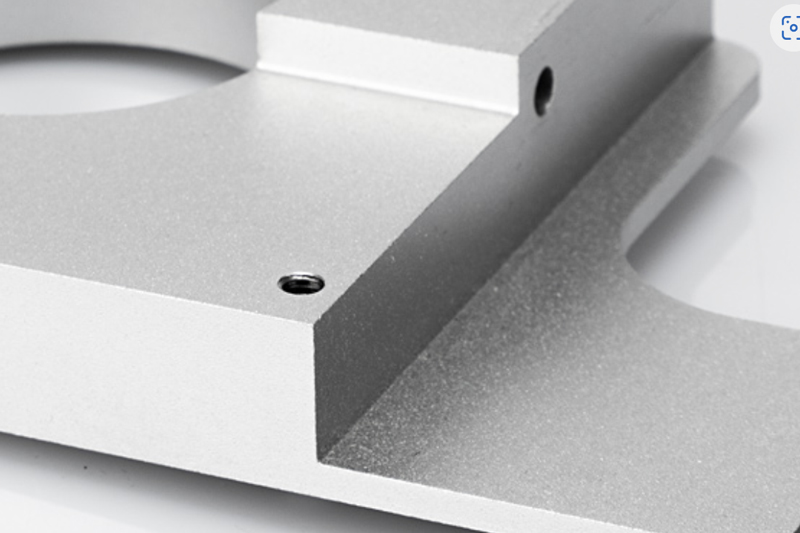

Ka li-50sets tse fetang 50 tsa mechini ea 3, 4, le 5-axis CNC ho fana ka mamello e phahameng ka ho fetesisa ho fihla ho ± 0.0008 ″ (0.02 mm) likarolo tsa ho sila tsa Precision CNC. Lebenkele la mochini oa marang-rang bakeng sa machining le tlhahiso ea mohlala.

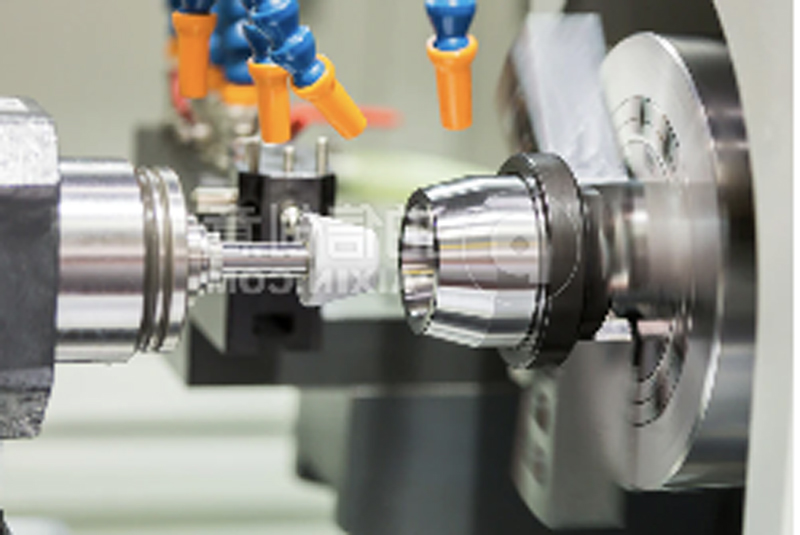

Tšebeletso ea ho fetola CNC

80+ CNC Lathes le litsi tsa ho fetola CNC, li ka fana ka lits'ebeletso tsa machining tse sebetsang hantle tse nang le karabelo e potlakileng. Baenjiniere ba litsebi ba lilemo tse 15+ ho tšehetsa ka lihlahisoa tse rarahaneng.

Motlakase oa ho Lahlela Motlakase(EDM)

Mokhoa o sa amaneng oa mochini oa meaho e bobebe. mefuta e 'meli ea ts'ebetso ea Motlakase oa Ts'ebetso ea Motlakase (EDM) eo re fanang ka eona, Wire EDM le Sinker EDM. Mekhoa e na le thuso bakeng sa ho khaola lipokotho tse tebileng le likarolo tse rarahaneng tse kang likere le masoba a nang le senotlolo.

Lisebelisoa tsa ho sebetsa tsa CNC

Tooling e potlakileng

CNC machining ke tharollo e phethahetseng ea ho etsa li-fixtures kapa hlobo. Machining a CNC a ka khaola mefuta e mengata e fapaneng e teteaneng ka botlalo, e tšoarellang joalo ka aluminium 5052 le tšepe e sa hloekang.

Prototyping e potlakileng

Li-prototype li tla be li lokile ka letsatsi le le leng. Re na le bo-machini ba nang le boiphihlelo ba 20+ ho ts'ehetsa li-prototypes tse potlakileng le tsa boleng bo holimo. Mefuta e fapaneng ea li-alloys tsa tšepe le li-plastiki li ka sebelisoa bakeng sa li-prototypes.

Tlhahiso ea ho Qetela

Mamello e matla e tlase joalo ka +/- 0.001 ", likhetho tse netefalitsoeng le mekhoa e fapaneng ea kalafo ea holim'a metsi li etsa hore CNC e be theknoloji e ntle haholo bakeng sa likarolo tse sebelisoang ho qetela.

Khetho ea Lisebelisoa tsa Mochini oa CNC ----- Metal

FCE e tla u thusa ho fumana lisebelisoa tse ntle ho latela tlhoko ea sehlahisoa le ts'ebeliso. Khetha pakeng tsa likhetho tse potlakileng le tse theko e tlaase ho fumana thepa e ntle ka ho fetisisa.

· CNC Machining Aluminium Alloys

Aluminium 6061

Aluminium 5052

Aluminium 2024

Aluminium 6063

Aluminium 7050

Aluminium 7075

Aluminium MIC-6

· CNC Machining Copper Alloys

Koporo 101

Koporo C110

·CNC Machining Bronze Alloys

Koporo C932

· CNC Machining Brass Alloys

Koporo 260

Koporo 360

· CNC Machining Stainless Steel Alloys

Nitronic 60 (218 SS)

Tšepe e sa hloekang 15-5

Tšepe e sa hloekang 17-4

Tšepe e sa hloekang 18-8

Sebetsa 303

Tšepe e se nang Mokelikeli 316/316L

Sebetsa 416

Tšepe e sa hloekang 410

Stainless Steel 420

Sebetsa 440C

· Lisebelisoa tsa tšepe tsa CNC Machining

Tšepe 1018

Tšepe 1215

tšepe 4130

tšepe 4140

tšepe 4140PH

tšepe 4340

Tšepe A36

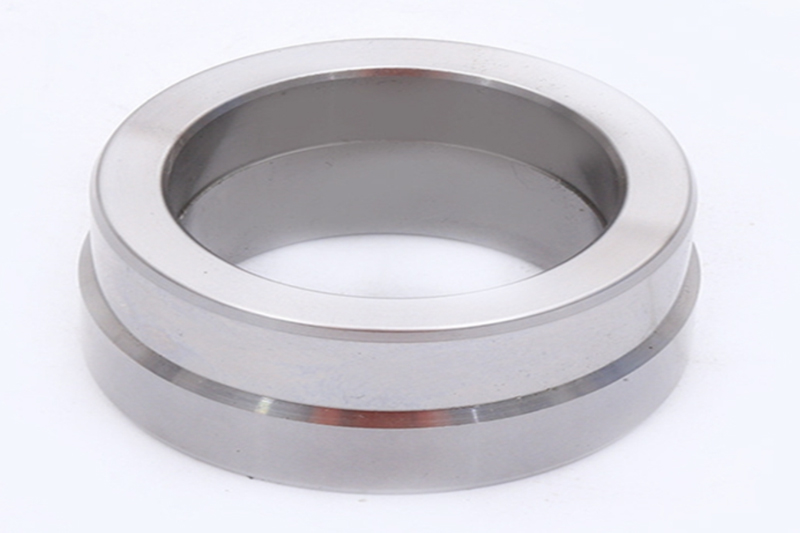

· CNC Machining Titanium Alloys

Titanium (Kereiti ea 2)

Titanium (Kereiti ea 5)

· CNC Machining Zinc Alloys

Motsoako oa Zinc

Khetho ea Lisebelisoa tsa Mechini ea CNC ------ Plastiki

FCE e tla u thusa ho fumana lisebelisoa tse ntle ho latela tlhoko ea sehlahisoa le ts'ebeliso. Khetha pakeng tsa likhetho tse potlakileng le tse theko e tlaase ho fumana thepa e ntle ka ho fetisisa.

· ABS

ABS e etsoa habonolo ka mekhoa e tloaelehileng ea machining, joalo ka ho phethola, ho sila, ho cheka le ho sakha.

·Akriliki

Plastiki e hlakileng e kang khalase, e atisa ho sebelisoa bakeng sa tšebeliso ea ka ntle. Lintho tse ntle tsa ho senya le ho senya.

·Delrin (Acetal)

Delrin e na le khanyetso e ntle ea mongobo, e hanyetsanang le ho roala haholo, le likhohlano tse tlase.

·Garolite G10

G10 e Matla, e khona ho sebetsa 'me e sireletsa motlakase. E entsoe ka resin ea epoxy e thibelang malakabe e nang le matlafatso ea lesela la fiberglass.

· HDPE

Polyethylene e phahameng haholo ke polasetiki e thibelang mongobo le lik'hemik'hale e nang le tšusumetso e ntle. Hangata e sebelisoa bakeng sa lisebelisoa tsa ka ntle, lijana tse sa keneleng metsi le litiiso.

· Nylon 6/6

Nylon 6/6 e ekelitse matla a mochini, ho tiea, botsitso bo botle tlasa mocheso le / kapa ho hanyetsa lik'hemik'hale.

· PC (Polycarbonate)

PC e na le thepa e phahameng ea mochini le ea sebopeho. E sebelisoa haholo likoloing, sebakeng sa lifofane, le lits'ebetsong tse ling tse hlokang ho tšoarella le botsitso.

·PEK

PEEK e atisa ho sebelisoa e le lisebelisoa tse bobebe bakeng sa likarolo tsa tšepe. Hangata e sebelisoa ka mocheso o phahameng, lits'ebetso tsa khatello ea maikutlo. PEEK e hanela lik'hemik'hale, ho roala le mongobo, e fanang ka matla a matla a ho tsitsa,

· Polypropylene

Polypropylene ke khanyetso ea lik'hemik'hale kapa ea kutu. E na le lisebelisoa tse ntle tsa motlakase 'me e monya hanyenyane kapa ha e na mongobo. E jara meroalo e bobebe nako e telele mochesong o fapaneng haholo.

·PTFE (Teflon)

PTFE e feta lipolasetiki tse ngata ha ho tluoa tabeng ea ho hanyetsa lik'hemik'hale le ts'ebetso ea mocheso o feteletseng. E hanela lihlapolli tse ngata 'me ke insulator e ntle ea motlakase.

·UHMW PE

Polyethylene e boima ba molek'hule e phahameng haholo. UHMW PE ha e monye mongobo 'me e fana ka motsoako o ikhethang oa ho roala le ho hanyetsa ho bola, khanyetso e phahameng ea lik'hemik'hale, khohlano e tlase ea holim'a metsi, matla a matla a matla.

· PVC

PVC e sebelisoa hangata libakeng tse pepesehileng marong kapa e hloka ho kenella ka motlakase. E boetse e na le polasetiki ea maiketsetso e hanyetsanang le lik'hemik'hale

CNC Machining Surface Finishes

E Tloaelehileng (Ha-Milled)

Ke mokhoa o potlakileng oa ho fetola machining. E na le bokaholimo ba 3.2 μm (126 μin). Lithako tsohle tse bohale lia tlosoa, 'me likarolo li tlosoa. Matšoao a lisebelisoa aa bonahala.

Ho phatloha ha Bead

Karolo e 'ngoe e sala e e-na le ponahalo e boreleli, e matte

Koetsoe

Ke mokhoa o potlakileng oa ho fetola machining. E na le bokaholimo ba 3.2 μm (126 μin). Lithako tsohle tse bohale lia tlosoa, 'me likarolo li tlosoa. Matšoao a lisebelisoa aa bonahala.

Anodized

Likarolo li ka etsoa ka anodized ka mebala e mengata e fapaneng - e hlakileng, e ntšo, e putsoa, e khubelu, e putsoa, khauta.

Boikemisetso

Likarolo li ka tšeloa ka anod ka mebala e mengata e fapaneng - e ntšo, e hlakileng, e khubelu le ea khauta.

Seaparo sa Powder

Likarolo li ka tšeloa ka anod ka mebala e mengata e fapaneng - e ntšo, e hlakileng, e khubelu le ea khauta.

Tataiso ea Moqapi oa Mochini oa CNC

| Sebopeho | Tlhaloso |

| Li-fillet tsa ka hare tsa sekhutlo | Etsa li-fillet tsa ka hare tsa sekhutlo hore li be 0.020" - 0.050" tse kholo ho feta boholo bo tloaelehileng ba ho cheka radii. Latela bophara ba ho cheka ho isa botebong ba tekanyo ea 1:6 (1:4 e khothalelitsoe) e le tataiso bakeng sa radii e ka hare ea hukung. |

| Li-fillets tsa fatše | Rala li-fillets tsa fatše tse nyane ho feta li-fillet tsa sekhutlo ho lumella sesebelisoa se tšoanang ho hlakola thepa kahare. |

| Li-undercuts | Kamehla etsa li-undercuts ho ea boholo bo tloaelehileng le hole le likhutlo e le hore li fihlellehe ka sesebelisoa sa ho itšeha. |

| Botebo ba lesoba le khoele | Fana ka tumello ea lisebelisoa ho feta botebo ba lesoba le tlatsitsoeng ho netefatsa likhoele tse felletseng. |

| Ho rarahana | Boloka palo ea likheo tse nyane bonyane ho fokotsa litšenyehelo tsa mochini oa CNC; moralo feela ka likarolo tse hlokahalang ho leka-lekanya tšebetso le bokhabane. |

CNC Machining Tolerances

| Sebopeho | Tlhaloso |

| Boholo ba Karolo ea Boholo | Likarolo tse haliloeng ho fihla ho 80" x 48" x 24" (2,032 x 1,219 x 610 mm). Lathe likarolo ho fihlela ho 62" (1,575 mm) bolelele le 32" (813 mm) bophara. |

| Nako e Tloaelehileng ea Ketapele | 3 matsatsi a khoebo |

| Kakaretso Mamello | Ho mamella litšepe ho tla tšoareloa ho +/- 0.005" (+/- 0.127 mm) ho latela ISO 2768 ntle le ha ho boletsoe ka tsela e 'ngoe. Plastiki le metsoako e tla ba +/- 0.010 ". |

| Precision Tolerances | FCE e ka etsa le ho lekola ho mamellana ho thata ho latela litlhaloso tsa hau tsa ho taka, ho kenyelletsa le li-callouts tsa GD&T. |

| Bonyane ba Sebopeho | 0.020” (0.50 limilimithara). Sena se ka fapana ho latela karolo ea geometry le thepa e khethiloeng. |

| Likhoele le Likoti tse Tapped | FCE e ka amohela boholo ba khoele e tloaelehileng. Hape re ka sebelisa likhoele tse tloaelehileng tsa mochini; tsena li tla hloka tlhahlobo ea qotso ka letsoho. |

| Boemo ba moeli | Lithako tse nchocho li robehile 'me li thijoa ka ho sa feleng |

| Surface Finish | Qetello e tloaelehileng e entsoe joalo ka mochini: 125 Ra kapa ho feta. Likhetho tse ling tsa ho qetela li ka hlalosoa ha u fumana quote. |

Tšepiso ea rona ea Boleng