Ka Mold Labeling

Mokhoa oa ho sebetsa oa CNC o fumanehang

Tsebo ea Boenjiniere le Tataiso

Sehlopha sa boenjiniere se tla u thusa ho ntlafatsa moralo oa karolo ea ho bopa, tlhahlobo ea GD&T, khetho ea thepa. 100% netefatsa hore sehlahisoa se na le bokhoni bo phahameng ba tlhahiso, boleng, traceability

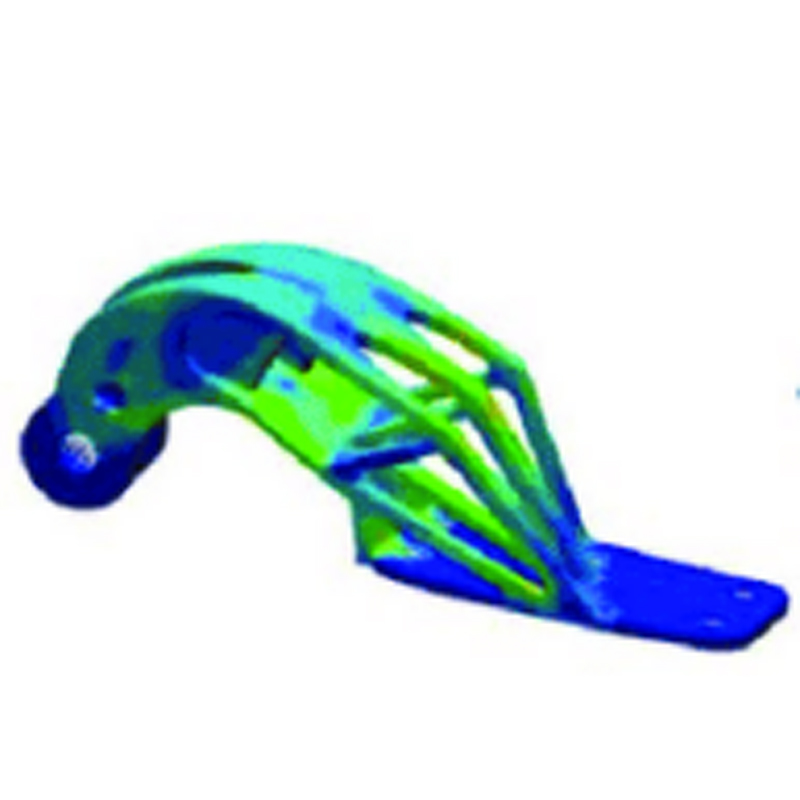

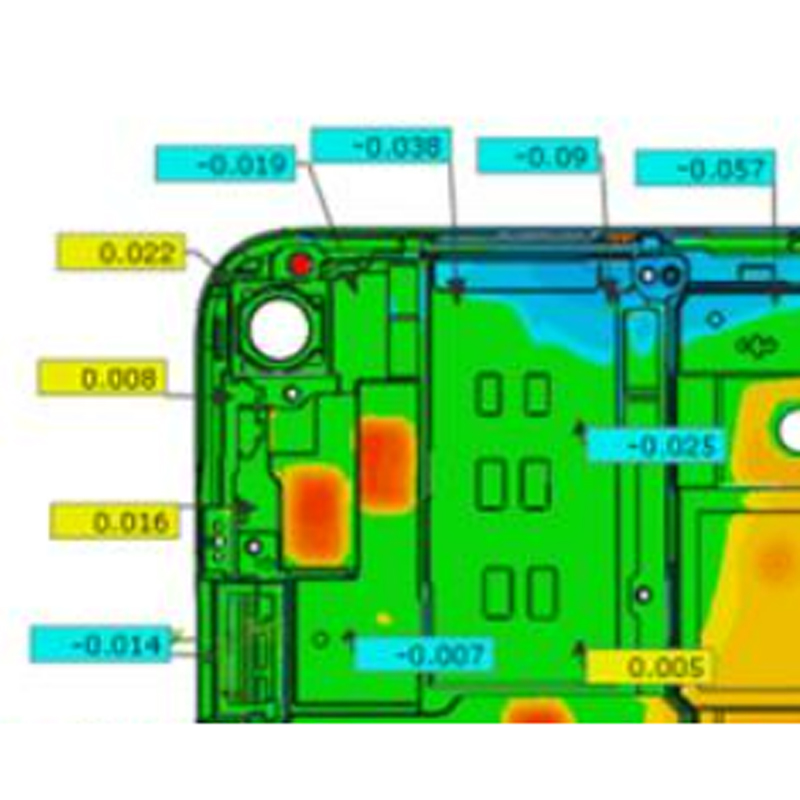

Ketsiso pele ho Cutting Steel

Bakeng sa khakanyo e 'ngoe le e' ngoe, re tla sebelisa mold-flow, Creo, Mastercam ho etsisa mokhoa oa ho bopa ente, ts'ebetso ea machining, mokhoa oa ho taka ho bolela esale pele taba pele u etsa lisampole tsa 'mele.

Moqapi oa Sehlahiswa o Ratang o Amogetswe

Re na le lisebelisoa tse holimo tsa tlhahiso ea lihlahisoa tsa ho etsa ente, mochini oa CNC le masela a tšepe. E lumellang moralo oa sehlahisoa o rarahaneng, o nepahetseng haholo o hlokahalang

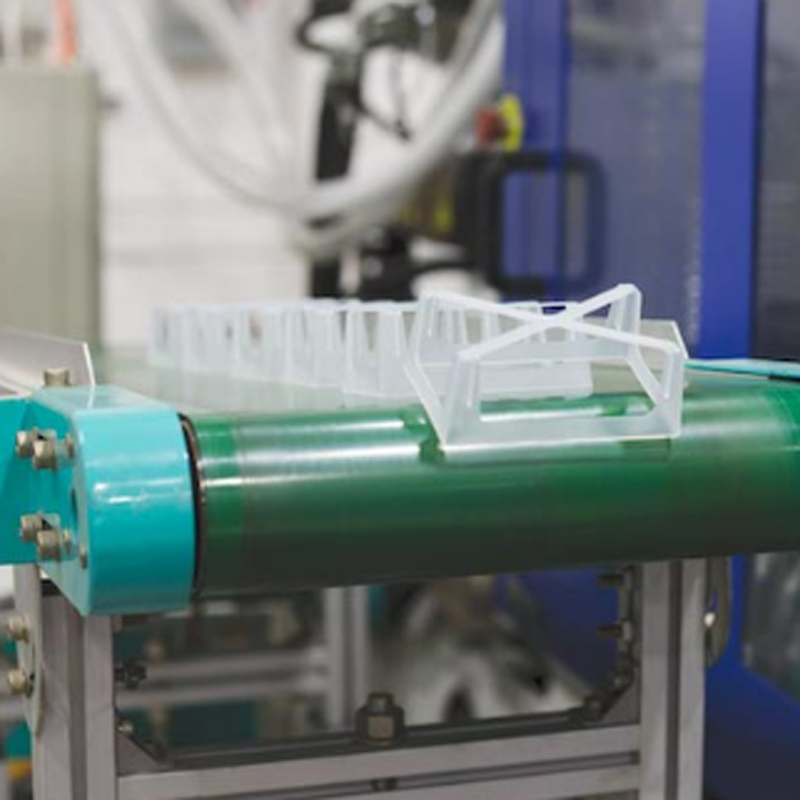

Ts'ebetsong ea ntlo

Ho etsa hlobo ea ente, mochini oa ente le ts'ebetso ea bobeli ea khatiso ea pad, staking ea mocheso, setempe se chesang, kopano kaofela li ka tlung, kahoo o tla ba le litšenyehelo tse tlase haholo le nako e tšepahalang ea nts'etsopele.

Ka Mold Labeling

Ho Mold Labeling (IML) ke mokhoa oa ho etsa ente moo mokhabiso oa karolo ea polasetiki, o sebelisa leibole, o hlahisoang nakong ea ente ea polasetiki. Ka mantsoe a bonolo feela, leibole e hatisitsoeng esale pele e kenngoa ka mokhoa oa boiketsetso ka mokoting oa hlobo ea ente ebe polasetiki e kenngoa holim'a label. Sena se hlahisa karolo ea polasetiki e khabisitsoeng / "e ngotsoeng" eo ho eona leibole e kopantsoeng ka ho sa feleng karolong ka boeona.

Melemo ea mekhoa ea ho ngola ka mould ea Rosti e kenyelletsa:

• Ho fihla ho 45% foil curvature (botebo ho isa bophara)

• Ts'ebetso ea mahala e omileng le e qhibilihang

• Se nang moeli moralo bokgoni

• Quick moralo phetoho

• Litšoantšo tse phahameng

• Theko e tlaase, haholo-holo bakeng sa merero e phahameng

• Finyella liphello tse ke keng tsa khoneha ka mekhoa e meng ea theknoloji

• E matla le e matla bakeng sa polokelo ea bohloeki ea lihlahisoa tse hatselitsoeng le tsa sehatsetsing

• Qetello e sa senyeheng

• Ho ela hloko tikoloho

Melemo ea IML

Melemo e meng ea tekheniki ea IML e kenyelletsa:

• Mokhabiso o feletseng oa karolo e bōpiloeng

• Ho tšoarella ha Grafiken: Li-inks li sirelelitsoe ke filimi meahong ea bobeli ea bokaholimo

• Mesebetsi ea bobeli e amanang le mokhabiso oa post-moulding e felisoa

• Ho felisoa ha tlhoko ea libaka tsa li-leibole tse recessed

• Lifilimi tse ngata le meaho e fumanehang ho fihlela litlhoko tsa bareki

• Ho bonolo ho hlahisa lisebelisoa tsa mebala e mengata

• Ka kakaretso ho theola likhahla tse fokolang

• E tšoarella haholoanyane le ho se kenye letsoho

• Ho leka-lekanya mebala e phahameng

• Ha ho sebaka seo litšila li ka bokellang ho sona

• Mebala e sa lekanyetsoang e teng

Ho Kopo ea Mold Labeling

Ho itšetlehile haholo ka monahano oa hau ho etsa qeto ea hore na ke merero efe e ka sebelisang mongolo oa mold, empa merero e tsoelang pele le e tlang ke ena;

- li-filters tsa tumbler tse omeletseng, ho iketsetsa tšebetsong ea phepelo

- ho tšoaea li-syringe le linkho

- likarolo tsa likhoutu le ho tšoaea indasteri ea likoloi

- ho iketsetsa lihlahisoa tsa indasteri ea meriana joalo-joalo

- traceability ea lihlahisoa tse nang le RFID

- ho khabisa ka lisebelisoa tse sa tloaelehang tse kang masela

Lenane le ka etsoa nako e telele haholo 'me bokamoso bo tla bontša tse ncha tse e-s'o utloe ka likopo tse tla etsa hore tlhahiso e be theko e tlaase le e potlakileng, ho ntlafatsa boleng le ho ntlafatsa polokeho, traceability le kabo.

Ka Boitsebiso ba Mold Labeling

Ho khomarela pakeng tsa lifolakha tse fapaneng le thepa ea overmoulding

| Lintho tse fetelletseng | |||||||||||||||||

| ABS | ASA | EVA | PA6 | PA66 | PBT | PC | PEHD | PELD | PET | PMMA | POM | PP | PS-HI | SAN | TPU | ||

| Lintho tse entsoeng ka foil | ABS | ++ | + | + | + | + | − | − | + | + | − | − | ∗ | + | + | ||

| ASA | + | ++ | + | + | + | − | − | + | + | − | − | − | + | + | |||

| EVA | + | + | ++ | + | + | + | + | + | |||||||||

| PA6 | ++ | + | ∗ | ∗ | ∗ | ∗ | − | ∗ | − | + | + | ||||||

| PA66 | + | ++ | ∗ | ∗ | ∗ | ∗ | − | − | − | + | + | ||||||

| PBT | + | + | ∗ | ∗ | ++ | + | − | − | + | − | − | − | − | + | + | ||

| PC | + | + | ∗ | ∗ | + | ++ | − | − | + | + | − | − | − | + | + | ||

| PEHD | − | − | + | ∗ | ∗ | − | − | ++ | + | − | ∗ | ∗ | − | − | − | − | |

| PELD | − | − | + | ∗ | ∗ | − | − | + | ++ | − | ∗ | ∗ | + | − | − | − | |

| PET | + | + | + | + | − | − | + | − | − | − | + | ||||||

| PMMA | + | + | − | − | ∗ | ∗ | − | ++ | ∗ | − | + | ||||||

| POM | − | − | − | − | − | − | ∗ | ∗ | − | ++ | − | − | − | ||||

| PP | − | − | + | ∗ | − | − | − | − | + | ∗ | − | ++ | − | − | − | ||

| PS-HI | ∗ | − | + | − | − | − | − | − | − | − | − | − | − | ++ | − | − | |

| SAN | + | + | + | + | + | + | + | − | − | + | − | − | − | ++ | + | ||

| TPU | + | + | + | + | + | + | − | − | + | − | − | + | + | ||||

++ Ho khomarela ka tsela e babatsehang, + Ho khomarela hantle, ∗ Ho khomarela ho fokolang, − Ha ho ho khomarela.

EVA, Ethylene vinyl acetate; PA6, Polyamide 6; PA66, Polyamide 66; PBT, Polybutylene terephthalate; PEHD, Polyethylene high density; PELD, Polyethylene low density; POM, Polyoxymethylene; PS-HI, Polystyrene High Impact; SAN, Styrene Acrylonitrile; TPU, Thermoplastic polyurethane.

Matla a amanang a IML vs. IMD labeling solutions

Ho kopanya mokhoa oa ho khabisa le mokhoa oa ho bopa ho eketsa nako e telele, ho fokotsa litšenyehelo tsa tlhahiso le ho etsa hore ho be bonolo ho etsa moralo.

Ho tšoarella

Litšoantšo ha li khone ho tlosa ntle le ho senya karolo ea polasetiki 'me e tla lula e le matla bakeng sa bophelo ba karolo eo. Likhetho li teng bakeng sa ho tšoarella ho matlafalitsoeng libakeng tse thata le ho hanyetsa lik'hemik'hale.

Katleho ea litšenyehelo

IML e felisa ho ngola ka mor'a ho bopa, ho tšoara le ho boloka. E fokotsa thepa ea WIP le nako e eketsehileng e hlokahalang bakeng sa mokhabiso oa ka morao ho tlhahiso, sebakeng sa marang-rang kapa se seng.

Ho feto-fetoha ha moralo

IML e fumaneha ka mefuta e mengata ea mebala, liphello, mekhoa le likhetho tsa litšoantšo 'me e ka etsisa le ponahalo e thata ka ho fetisisa e kang tšepe e sa hloekang, lijo-thollo tsa lehong le carbon fiber. Ha ho hlokahala setifikeiti sa UL, lisampole tsa label tse ka har'a hlobo li hlahlojoa ho latela maemo a ts'ireletso a ts'oanang a sebelisoang ho lekola lileibole tse sa utloeng khatello.