Inkonzo yokuBumba isitofu

UbuNgcali bobuNjineli kunye nesiKhokelo

Iqela lobunjineli liya kukunceda ekwandiseni uyilo lwenxalenye yokubumba, ukujonga i-GD&T, ukukhetha izinto. I-100% iqinisekisa imveliso enokuveliswa okuphezulu, umgangatho, ukulandelwa

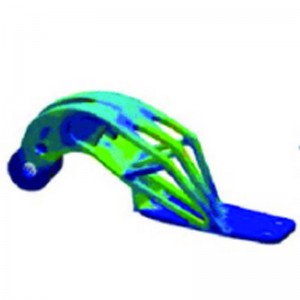

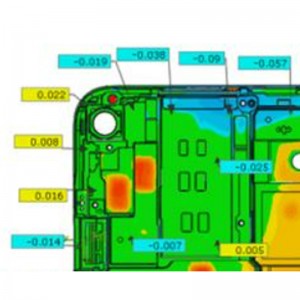

Ukulinganisa ngaphambi kokuSika iNsimbi

Kuqikelelo ngalunye, siya kusebenzisa i-mold-flow, iCreo, i-Mastercam ukulinganisa inkqubo yokubumba isitofu, inkqubo yomatshini, inkqubo yokuzoba ukuqikelela umba ngaphambi kokwenza iisampulu zomzimba.

Ukwenziwa kweMveliso eyiNgxaki echanekileyo

Sinezona ndawo ziphezulu zokwenza ibhrendi ekubumbeni inaliti, umatshini weCNC kunye nokwenziwa kwentsimbi. Nto leyo evumela ukuba intsonkothile, imfuneko yoyilo lwemveliso oluchanekileyo

Kwinkqubo yendlu

Ukwenza i-injection mold, isitofu sokubumba kunye nenkqubo yesibini yoshicilelo lwepad, ubushushu bobushushu, isitampu esishushu, indibano zonke zisendlini, ke uya kuba neendleko eziphantsi kakhulu kunye nexesha elithembekileyo lophuhliso.

Inkqubo ekhoyo

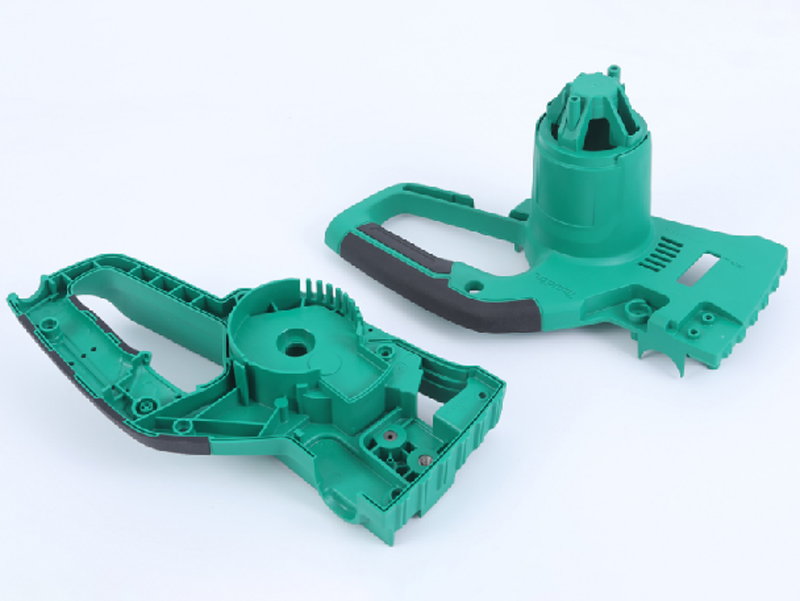

Overmolding

I-Overmolding ikwabizwa ngokuba yi-multi-k naliti yokubumba. yinkqubo eyodwa edibanisa izinto ezimbini okanye ezininzi, imibala kunye. Yeyona ndlela ilungileyo yokufikelela kwimibala emininzi, ubulukhuni obuninzi, imigangatho emininzi kunye nemveliso yokuziva. Kananjalo zisetyenziswe kwishothi enye ibe nomda ongenakufikelelwa kwimveliso.

Overmolding

I-Overmolding ikwabizwa ngokuba yi-multi-k naliti yokubumba. yinkqubo eyodwa edibanisa izinto ezimbini okanye ezininzi, imibala kunye. Yeyona ndlela ilungileyo yokufikelela kwimibala emininzi, ubulukhuni obuninzi, imigangatho emininzi kunye nemveliso yokuziva. Kananjalo zisetyenziswe kwishothi enye ibe nomda ongenakufikelelwa kwimveliso.

Ukubumba inaliti yeRubha yeSilicone

Irabha ye-Silicone ye-Liquid (LSR) yindlela yokuvelisa i-Silicone echanekileyo. Kwaye kuphela kwendlela yokuba nenxalenye yerabha ecacileyo (engafihliyo). Inxalenye yeSilicone yomelele nakwi 200degree temp. ukumelana neekhemikhali, izinto zebakala lokutya.

Kwimihombiso yokubumba

Kwimihlobiso yokubumba (IMD) yinkqubo elula nesebenzayo. Uhombiso lwenziwa ngaphakathi kubumba ngaphandle kwenkqubo yangaphambili / yesibini. Ukuhlobisa kugqityiwe, kubandakanywa nokukhusela idyasi eqinile, kunye nokubumba okukodwa nje. Vumela imveliso ibe neepateni zesiko, iglosi kunye nemibala.

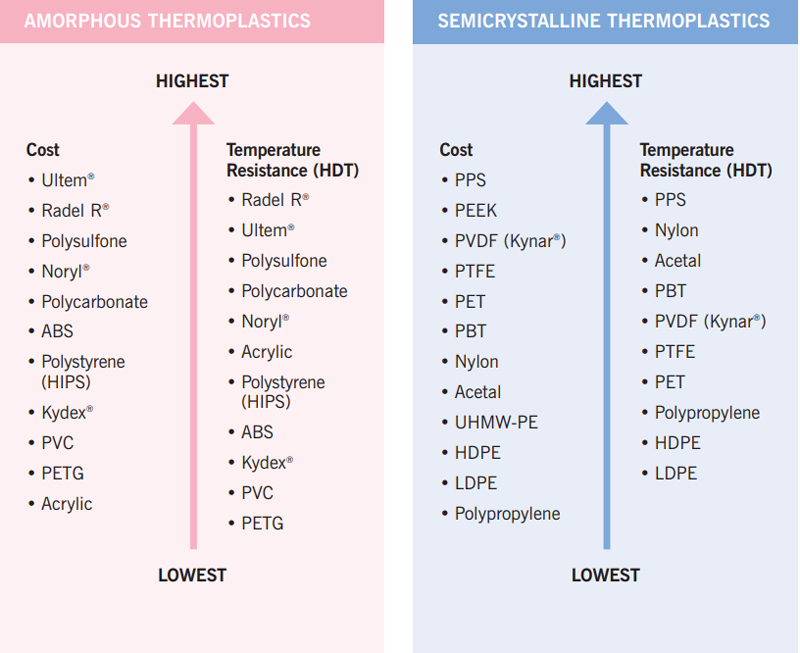

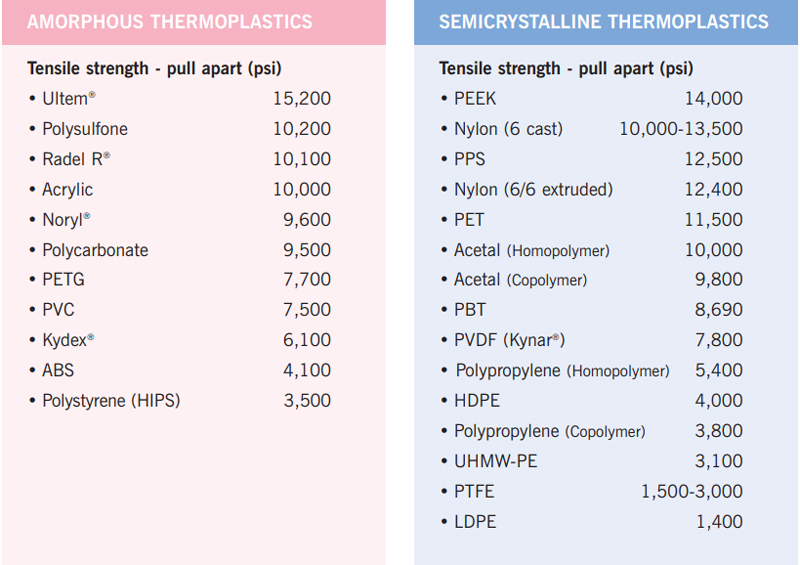

Ukukhethwa kwezinto

I-FCE iya kukunceda ufumane eyona mathiriyeli ngokweemfuno zemveliso kunye nokusetyenziswa kwayo. Kukho izinto ezininzi onokukhetha kuzo kwimarike, siya kuthi kwakhona ngokweendleko ezisebenzayo kunye nozinzo lwekhonkco lokubonelela ukucebisa uphawu kunye nebakala leresin.

Inxalenye ebunjiweyo Iyagqibezela

| Menyezela | I-Semi-Glossy | Matte | Ithunyiwe |

| SPI-A0 | SPI-B1 | SPI-C1 | MT (Moldtech) |

| I-SPI-A1 | SPI-B2 | SPI-C2 | VDI (Verein Deutscher Ingenieure) |

| I-SPI-A2 | SPI-B3 | SPI-C3 | YS (Yick Sang) |

| I-SPI-A3 |

I-Plastiki Isitofu sokuBumba izakhono

Iinkqubo zeSekondari

Ubushushu Staking

Ubushushu kwaye Cinezela ufakelo lwentsimbi okanye enye inxalenye yemathiriyeli eqinileyo kwimveliso. Emva kokuba into enyibilikayo iqine, idityaniswe kunye. Isiqhelo kwimisonto yobhedu.

Umzobo weLaser Phawula iipateni kwimveliso ngelaser. Ngezinto ezibuthathaka ze-laser, sinokuba nophawu olumhlophe lwelaser kwindawo emnyama.

Ushicilelo lwePad/ushicilelo lwesikrini

I-inki yokuprinta kumphezulu wemveliso, ukuprintwa kwemibala emininzi kwamkelwe.

I-NCVM kunye nePainting Ukuba nombala owahlukileyo, uburhabaxa, isiphumo sesinyithi kunye nesiphumo esichasene nomkrwelo womphezulu. Ngokuqhelekileyo kwiimveliso zokuthambisa.

Ultrasonic Plastic Welding

Inxalenye ezimbini ezidibeneyo kunye namandla e-Ultrasonic, indleko esebenzayo, itywina elihle kunye ne-cosmetic.

FCE Injection yokubumba izisombululo

Ukusuka kwingcamango ukuya kwinyani

Isixhobo somfuziselo

Ukuqinisekiswa koyilo olukhawulezayo kunye nemathiriyeli yokwenyani kunye nenkqubo, iprototype ekhawulezayo yezixhobo zentsimbi sisisombululo esihle kuyo. Isenokuba yibhulorho yemveliso nayo.

- Akukho mda uphantsi weodolo

- Uyilo oluntsonkothileyo luyafezekiswa

- 20k ubomi isixhobo sokudubula buqinisekisiwe

Izixhobo zokuvelisa

Ngokuqhelekileyo ngentsimbi eqinile, inkqubo yembaleki eshushu, intsimbi eqinile. Ubomi besixhobo bumalunga ne-500k ukuya kwi-1million shots. Ixabiso lemveliso yeyunithi liphantsi kakhulu, kodwa ixabiso lokungunda liphezulu kunesixhobo somzekelo

- Ngaphezulu kwesigidi seeshoti

- Ukusebenza okuphezulu kunye neendleko zokuqhuba

- Umgangatho wemveliso ephezulu

Inkqubo yoPhuhliso eqhelekileyo

Caphula ngeDFx

Jonga idatha yakho yemfuno kunye nezicelo, unikeze iimeko zesicatshulwa ngeengcebiso ezahlukeneyo. Ingxelo yokulinganisa kufuneka ibonelelwe ngaxeshanye

Jonga iprototype (enye)

Phuhlisa isixhobo esikhawulezayo (1 ~ 2wks) ukubumba iisampuli zeprototype zoyilo kunye nokuqinisekiswa kwenkqubo yokubumba

Uphuhliso lokungunda lwemveliso

Ungayikhaba irempu ngokukhawuleza ngesixhobo somzekelo. Ukuba imfuno engaphezulu kwezigidi, qalisa i-mold yemveliso kunye ne-multi-cavitation ngokuhambelanayo, eya kuthatha malunga. 2 ~ 5 iiveki

Phinda Umyalelo

Ukuba ugxininise kwimfuno, sinokuqala ukuhanjiswa ngaphakathi kwe-2days. Akukho myalelo wokugxila, sinokuqala ukuthunyelwa ngokuyinxenye nje ngeentsuku ezi-3

Q&A

Yintoni ukubumba inaliti?

Isitofu sokubumba ziziqingatha ezibini zokungunda zentsimbi ezidibanayo, iplastiki okanye imathiriyeli yerabha itofwe kumngxuma. Izinto zeplastiki ezitofwayo ziyanyibilika, azifudumezi ncam; Izinto eziphathekayo zicinezelwe kwisitofu ngesango lombaleki. Njengoko izinto zixinzelelwe, zitshisa kwaye ziqala ukugeleza kwiimbumba. Emva kokuba ipholile, iziqingatha ezibini ziyahlukana kwakhona kwaye inxalenye iyaphuma. Phinda kwakhona izenzo ezifanayo ukusuka ekuvaleni ukungunda kunye nokuvula ukungunda njengesangqa esinye, kwaye unenaliti yeendawo ezibunjiweyo ezilungeleyo.

Ngawaphi amashishini asebenzisa isitofu sokubumba?

Imimandla eyahlukeneyo ingasetyenziswa koku kulandelayo:

EzoNyango kunye nezoNyango

Electronics

Ukwakhiwa

Ukutya & nesiselo

Iimoto

Izinto zokudlala

Impahla zomthengi

Amakhaya

Zeziphi iintlobo zeenkqubo zokubumba inaliti?

Kukho iintlobo ezininzi zeenkqubo zokubumba inaliti, kuquka:

Isiko lokubumba inaliti yeplastiki

Overmolding

Faka ukubumba

Ukubumba inaliti yokuncedisa igesi

Ukubumba inaliti yerabha yerabha elulwelo

Isitofu sesinyithi sokubumba

Isitofu sokuphendula ukubumba

Ingaba isitofu sokungunda sihlala ixesha elingakanani?

Kuxhomekeke kwizinto ezininzi: izinto zokubumba, inani lemijikelezo, iimeko zokusebenza, kunye nokupholisa / ukubamba ixesha loxinzelelo phakathi kokuqhutywa kwemveliso.

Uthini umahluko phakathi kokubumba kunye nokubumba?

Nangona kufana kakhulu, umahluko phakathi kokubumba kunye nokubumba wehla kwiimpawu zabo ezizodwa kunye neenzuzo, kuxhomekeke kwisicelo abasetyenziselwa sona. Isitofu sokubumba silungele ngakumbi ukubaleka kwemveliso enkulu. I-Thermoforming, ifaneleke ngakumbi kwimveliso emfutshane yoyilo loyilo olukhulu kwaye ibandakanya ukwenza amaphepha eplastiki ashushu kumphezulu wokungunda.