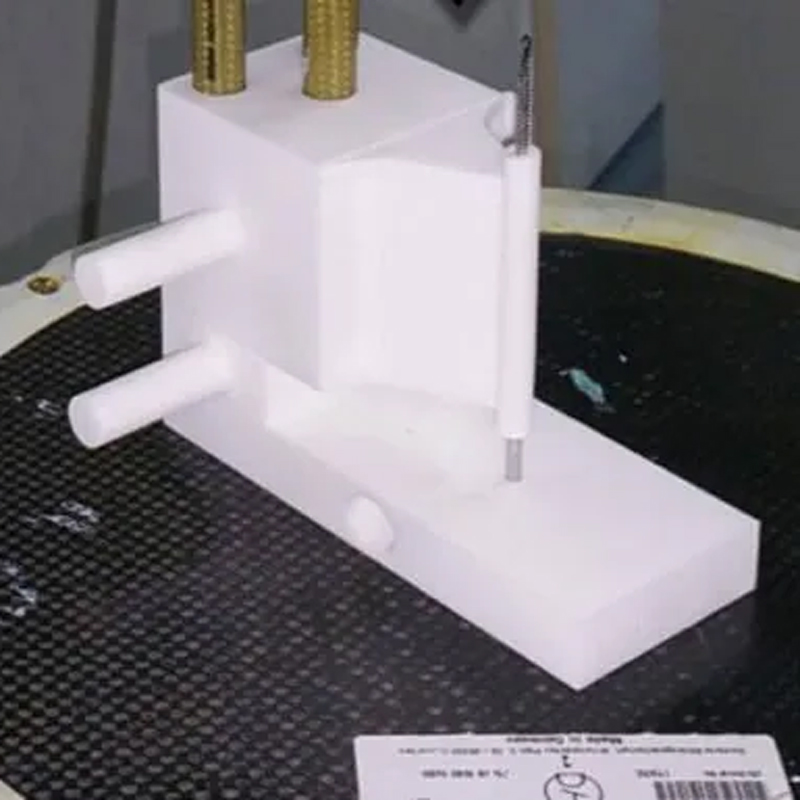

SLA

SLA Design guide

Isisombululo sokuprinta

Ubungqingqwa bomaleko omgangatho: 100 µm Ukuchaneka: ±0.2% (nomlinganiselo osezantsi ±0.2 mm)

Ubungakanani bomlinganiselo 144 x 144 x 174 mm Ubuncinci ubukhulu Ubuncinane bobukhulu bodonga 0.8mm – Ngomlinganiselo we-1:6

Ukukrola kunye ne-Embossing

Ubuncinci bobude kunye neenkcukacha zobubanzi I-Embossed: 0.5 mm

Ukroliwe: 0.5 mm

Ivolumu evaliweyo & edibeneyo

Iindawo ezivalelweyo? Ayikhuthazwa iindawo zokuThintelana? Ayikhuthazwa

Isithintelo sendibano yeqhekeza

INdibano? Hayi

UbuNgcali bobuNjineli kunye nesiKhokelo

Iqela lobunjineli liya kukunceda ekwandiseni uyilo lwenxalenye yokubumba, ukujonga i-GD&T, ukukhetha izinto. I-100% iqinisekisa imveliso enokuveliswa okuphezulu, umgangatho, ukulandelwa

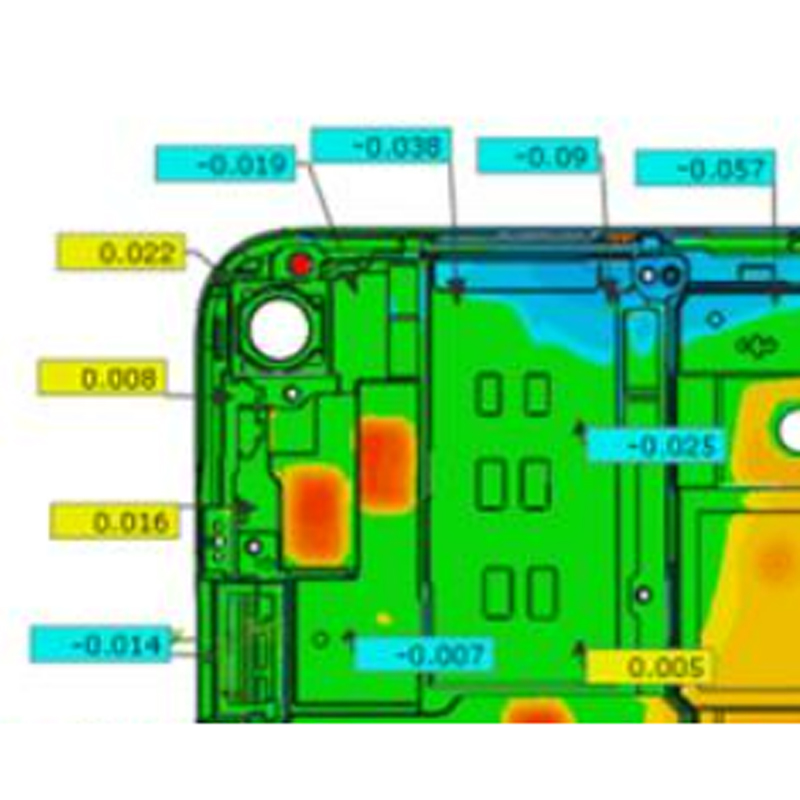

Ukulinganisa ngaphambi kokuSika iNsimbi

Kuqikelelo ngalunye, siya kusebenzisa i-mold-flow, iCreo, i-Mastercam ukulinganisa inkqubo yokubumba isitofu, inkqubo yomatshini, inkqubo yokuzoba ukuqikelela umba ngaphambi kokwenza iisampulu zomzimba.

Uyilo lweMveliso entsonkothileyo

Sinezona ndawo ziphezulu zokwenza ibhrendi ekubumbeni inaliti, umatshini weCNC kunye nokwenziwa kwentsimbi. Nto leyo evumela ukuba intsonkothile, imfuneko yoyilo lwemveliso oluchanekileyo

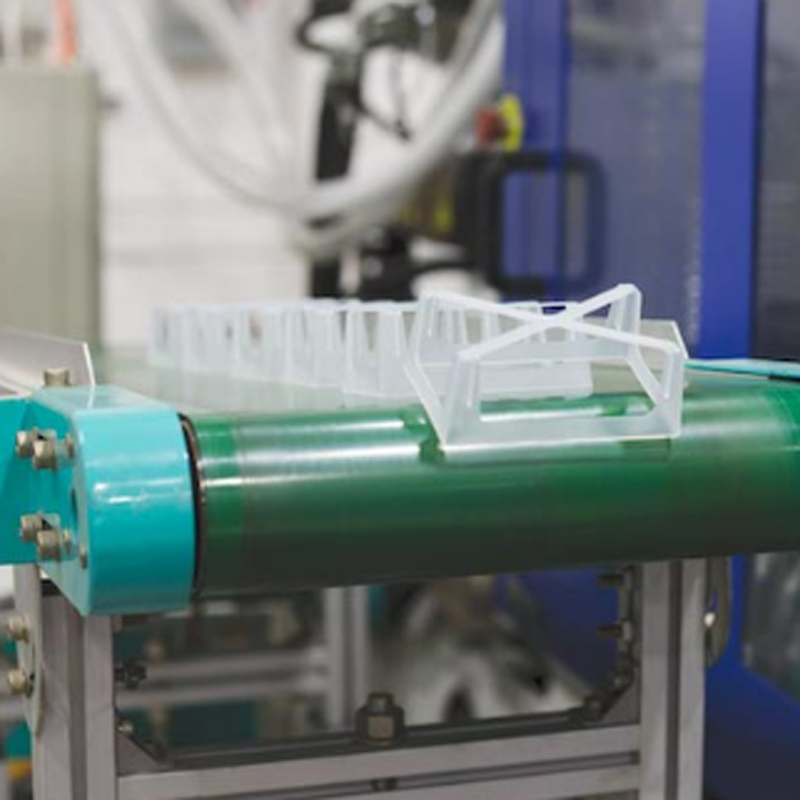

Kwinkqubo yendlu

Ukwenza i-injection mold, isitofu sokubumba kunye nenkqubo yesibini yoshicilelo lwepad, ubushushu bobushushu, isitampu esishushu, indibano zonke zisendlini, ke uya kuba neendleko eziphantsi kakhulu kunye nexesha elithembekileyo lophuhliso.

Iinzuzo ze-SLA Printing

Inqanaba eliphezulu leenkcukacha

Ukuba ufuna ukuchaneka, i-SLA yinkqubo yokuvelisa eyongezelelweyo oyifunayo ukwenza iprototypes eneenkcukacha kakhulu.

izicelo ezahlukeneyo

Ukusuka kwiimoto ukuya kwiimveliso zabathengi, iinkampani ezininzi zisebenzisa iStereolithography kwiprototyping ekhawulezayo

Inkululeko yoyilo

Imveliso eqhutywa kuyilo ikuvumela ukuba uvelise iijiyometri ezinzima

Isicelo se-SLA

Iimoto

Ukhathalelo lwempilo kunye noNyango

Oomatshini

Ubuchwephese obuphezulu

IiMpahla zoShishino

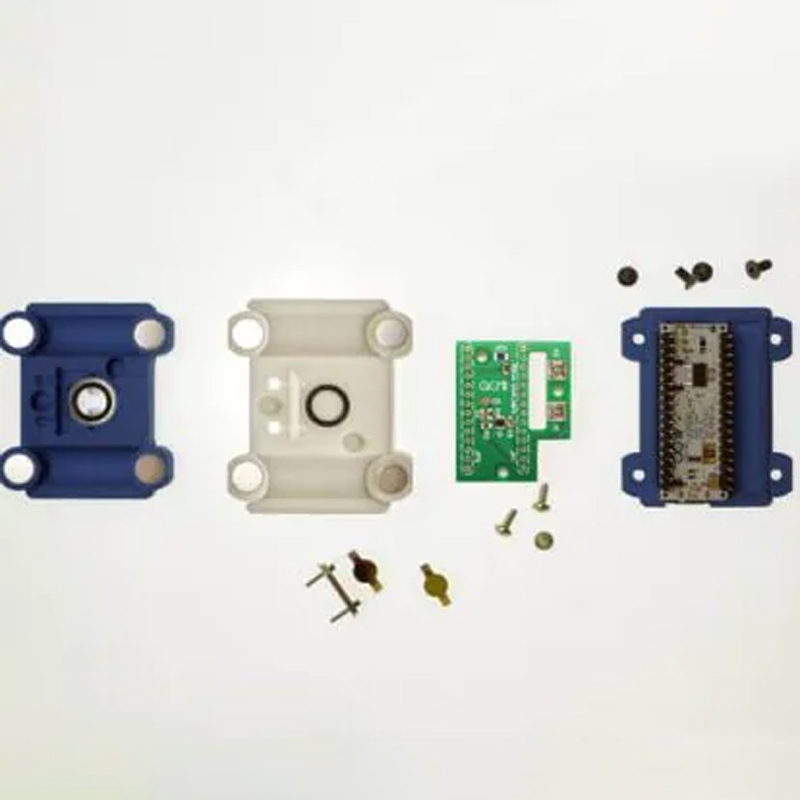

Electronics

SLA vs SLS vs FDM

| Igama lePropati | I-Stereolithography | Ukukhetha iLaser Sintering | iFused Deposition Modeling |

| Ushunqulelo | SLA | SLS | FDM |

| Uhlobo lwezinto | Ulwelo (Photopolymer) | Umgubo (Polymer) | Iqinile (Imicu) |

| Izinto eziphathekayo | Thermoplastics (Elastomers) | I-Thermoplastics efana neNylon, iPolyamide, kunye nePolystyrene; iielastomers; Iimbumba | Thermoplastics ezifana ABS, Polycarbonate, kunye Polyphenylsulfone; Iielastomers |

| Ubungakanani benxalenye enkulu (ngaphakathi) | 59.00 x 29.50 x 19.70 | 22.00 x 22.00 x 30.00 | 36.00 x 24.00 x 36.00 |

| Ubuncinci besayizi yefitsha (in.) | 0.004 | 0.005 | 0.005 |

| Ubungqingqwa bomaleko obuncinci (ngaphakathi.) | 0.0010 | 0.0040 | 0.0050 |

| Ukunyamezela (in.) | ±0.0050 | ±0.0100 | ±0.0050 |

| Ukugqitywa komphezulu | Mhle | I-avareji | rhabaxa |

| Yakha isantya | I-avareji | Ukukhawuleza | Cotha |

| Usetyenziso | Uvavanyo lweFom/ukufaneleka, Uvavanyo olusebenzayo, iipatheni zesixhobo eziKhawulezayo, ukulingana okukhawulezileyo, iindawo ezineenkcukacha kakhulu, imifuziselo yokubonisa, ubushushu obuphezulu. | Uvavanyo lwefomu/lolulungeleyo, Uvavanyo olusebenzayo, iipatheni zesixhobo eziKhawulezayo, Amacandelo angenankcukacha, Amacandelo ane-snap-fits & neehenjisi eziphilayo, Ukusetyenziswa kobushushu obuphezulu. | Uvavanyo lweFom/lolulungeleyo, Uvavanyo olusebenzayo, iipatheni zezixhobo eziKhawulezayo, Amacandelo amancinci anenkcukacha, imifuziselo yokubonisa, izigulane kunye nosetyenziso lokutya, izicelo zobushushu obuphezulu. |

SLA Advantage

I-Stereolithography ikhawuleza

I-Stereolithography ichanekile

I-Stereolithography isebenza kunye nezixhobo ezahlukeneyo

Uzinzo

IiNdibano ezinamaCandelo amaninzi zinokwenzeka

Uthungelwano lweTeksi lunokwenzeka