Inkonzo yoMatshini ye-CNC

CNC Machining Inkqubo ekhoyo

Inkonzo yokugaya i-CNC

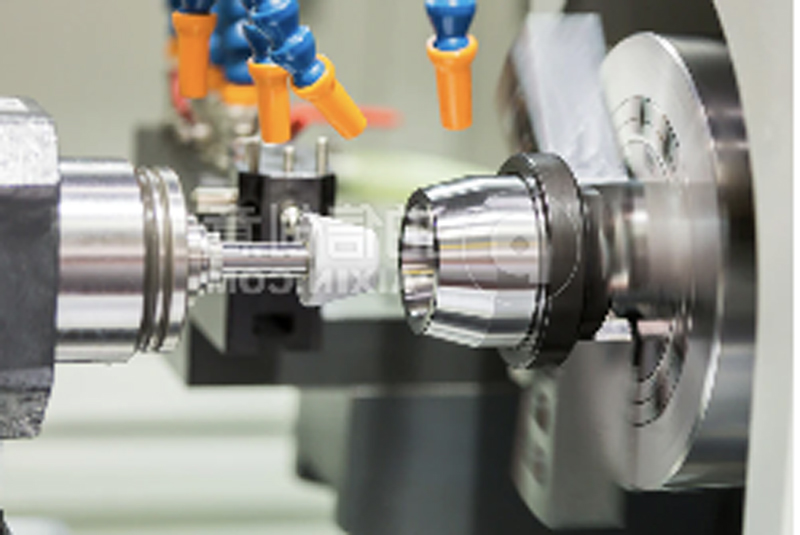

Ngaphezulu kweeseti ze-50 ze-3, i-4, kunye ne-5-axis ye-CNC koomatshini ukunika unyamezelo oluphezulu ukuya kuthi ga kwi-±0.0008″ (0.02 mm) iindawo zokusila ezichanekileyo ze-CNC. Ivenkile yoomatshini kwi-Intanethi yeprototype machining kunye nemveliso.

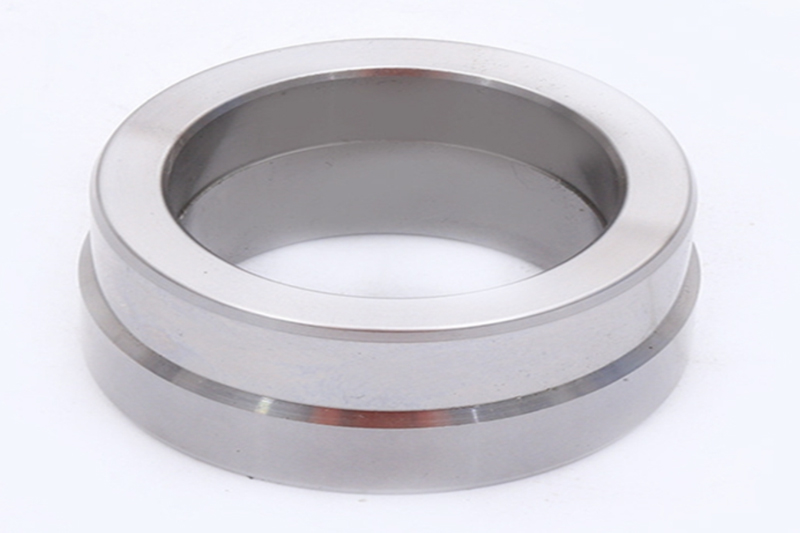

Inkonzo yokuguqula i-CNC

I-80+ ye-CNC Lathes kunye namaziko okuguqula i-CNC, inokubonelela ngeenkonzo ezichanekileyo ze-machining zeendleko kunye nokuphendula ngokukhawuleza. Iminyaka eyi-15+ yeenjineli zobuchwephesha ukuxhasa ngeemveliso ezinzima.

Umatshini wokukhupha uMbane (EDM)

Indlela yomatshini engaqhagamshelwanga kwizakhiwo ezibuthathaka. iintlobo ezimbini zeenkqubo zokuSebenza koMbane (EDM) esizinikezelayo, i-Wire EDM kunye ne-Sinker EDM. Iinkqubo ziluncedo ukusika iipokotho ezinzulu kunye neempawu ezinzima ezifana neegiya kunye nemingxuma enesitshixo.

CNC Machining Applications

Rapid Tooling

I-CNC machining sisisombululo esigqibeleleyo sokudala izixhobo okanye ukubumba. Umatshini we-CNC unokusika iindidi eziphezulu zezixhobo ezixinene ngokupheleleyo, ezihlala ixesha elide njenge-aluminium 5052 kunye nentsimbi engatyiwayo.

Ukuchwetheza ngokukhawuleza

Iiprototypes ukuba zilungele ngosuku olu-1. Sine-20+ yoomatshini abanezakhono zokuxhasa iiprototypes ezikhawulezayo nezikumgangatho ophezulu. Iintlobo ngeentlobo zealloyi zentsimbi ezifikelelekayo kunye neeplastiki zingafakwa kwiiprototypes.

Ukuphela koMveliso wokusetyenziswa

Unyamezelo oluqinileyo olusezantsi njenge +/- 0.001”, iinketho zemathiriyeli eziqinisekisiweyo kunye neenkqubo ezahlukeneyo zonyango lomphezulu zenza ukuba i-CNC isebenze itekhnoloji egqwesileyo yokusetyenziswa kokuphela.

CNC Machining Ukukhethwa kweMathiriyeli----Metal

I-FCE iya kukunceda ufumane eyona mathiriyeli ngokweemfuno zemveliso kunye nokusetyenziswa kwayo. Khetha phakathi kweenketho ezikhawulezayo nezingabizi kakhulu ukufumana ezona zinto zilungileyo.

·CNC Machining Aluminiyam Alloys

IAluminiyam 6061

IAluminiyam 5052

IAluminiyam 2024

IAluminiyam 6063

IAluminiyam 7050

IAluminiyam 7075

IAluminiyam iMIC-6

·CNC Machining Copper Alloys

Ubhedu 101

Ubhedu C110

·CNC Machining Bronze Alloys

Ubhedu C932

·CNC Machining Brass Alloys

Ubhedu 260

Ubhedu 360

·CNC Machining Stainless Steel Alloys

I-Nitronic 60 (218 SS)

Intsimbi yentsimbi 15-5

Intsimbi engatyiwa 17-4

Intsimbi engatyiwa 18-8

iStainless Steel 303

iStainless Steel 316/316L

iStainless Steel 416

iStainless Steel 410

iStainless Steel 420

iStainless Steel 440C

· CNC Machining Steel Alloys

Intsimbi 1018

Intsimbi 1215

Intsimbi 4130

Intsimbi 4140

Intsimbi 4140PH

Intsimbi 4340

Intsimbi A36

·CNC Machining Titanium Alloys

I-Titanium (iBanga lesi-2)

I-Titanium (iBanga lesi-5)

·CNC Machining Zinc Alloys

Ingxubevange yeZinc

CNC Machining Ukukhethwa kweMathiriyeli---- Iplastiki

I-FCE iya kukunceda ufumane eyona mathiriyeli ngokweemfuno zemveliso kunye nokusetyenziswa kwayo. Khetha phakathi kweenketho ezikhawulezayo nezingabizi kakhulu ukufumana ezona zinto zilungileyo.

·ABS

I-ABS yenziwa lula ngobuchule obuqhelekileyo bomatshini, obufana nokujika, ukungqusha, ukugrumba kunye nokusarha.

·Akriliki

Iplastiki ecacileyo efana neglasi, isetyenziswa ngokuqhelekileyo ukusetyenziswa ngaphandle. Iimpawu ezilungileyo zokunxiba kunye nokukrazula.

·Delrin (Acetal)

IDelrin inokumelana nokufuma okuhle, ukuxhathisa okuphezulu, kunye nokukhuhlana okuphantsi.

·Garolite G10

I-G10 yomelele, iyakwazi ukusebenza kwaye iyakhusela ngombane. Yenziwe ngeresin ye-epoxy engagabi lidangatye kunye nokuqinisa ilaphu le-fiberglass.

·HDPE

I-Polyethylene yoxinaniso oluphezulu kukufuma kunye neplastiki enganyangekiyo ngemichiza enegunya lempembelelo elungileyo. Ngokuqhelekileyo isetyenziselwa usetyenziso lwangaphandle, izitya ezingenamanzi kunye netywina.

· Inayiloni 6/6

Inayiloni 6/6 yandisa amandla omatshini, ukuqina, ukuzinza okuhle phantsi kokubonelela ngobushushu kunye / okanye ukuxhathisa imichiza.

·PC (Polycarbonate)

I-PC ineempawu eziphezulu zoomatshini kunye nezakhiwo. Isetyenziswa ngokubanzi kwiimoto, kwi-aerospace, kunye nezinye izicelo ezifuna ukuqina kunye nozinzo.

·PEEK

I-PEEK isoloko isetyenziswa njengenye imathiriyeli ekhaphukhaphu kwiindawo zentsimbi. Ngokuqhelekileyo isetyenziselwa ubushushu obuphezulu, izicelo zoxinzelelo oluphezulu. I-PEEK ixhathisa iikhemikhali, ukunxiba, kunye nokufuma, inika amandla okuqina,

·Polypropylene

I-Polypropylene yikhemikhali okanye ukuxhathisa ukubola. Ineempawu ezibalaseleyo zombane kunye nokufunxa okuncinci okanye akukho nto ukufuma. Ithwala imithwalo elula ixesha elide kumaqondo obushushu ahluka kakhulu.

·PTFE (Teflon)

I-PTFE yodlula iiplastiki ezininzi xa kufikwa kukumelana neekhemikhali kunye nokusebenza kumaqondo obushushu agqithisileyo. Iyaxhathisa uninzi lwezinyibilikisi kwaye sisisithinteli sombane esigqwesileyo.

·UHMW PE

I-polyethylene enesisindo esiphezulu semolekyuli. I-UHMW PE ayifunxa ukufuma kwaye inika indibaniselwano ekhethekileyo yokunxiba kunye nokumelana nokugqwala, ukuxhathisa imichiza ephezulu, ukungqubana komphezulu ophantsi, amandla anempembelelo ephezulu.

·PVC

I-PVC iqhele ukusetyenziswa kwiindawo ezivezwe kulwelo okanye ifuna ukugqunywa kombane. Kwaye ikwayiplastiki ekwaziyo ukumelana neekhemikhali

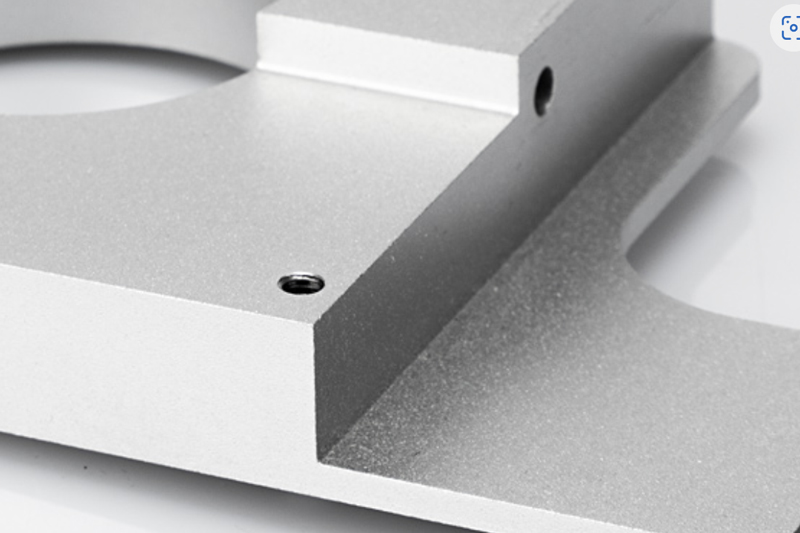

CNC Machining Surface Ukugqiba

Umgangatho (Njengoko-Milled)

Yeyona nkqubo ikhawulezayo yokuguqula umatshini. Inobuso oburhabaxa obuyi-3.2 μm (126 μin). Yonke imiphetho ebukhali iyasuswa, kwaye iinxalenye zihlanjululwe. Iimpawu zesixhobo ziyabonakala.

Bead Blast

Umphezulu wenxalenye ushiywe kunye nenkangeleko egudileyo, matte

Ikhutshiwe

Yeyona nkqubo ikhawulezayo yokuguqula umatshini. Inobuso oburhabaxa obuyi-3.2 μm (126 μin). Yonke imiphetho ebukhali iyasuswa, kwaye iinxalenye zihlanjululwe. Iimpawu zesixhobo ziyabonakala.

Anodized

Amalungu anokuthi afakwe nge-anodized ngemibala emininzi eyahlukeneyo-ecacileyo, emnyama, engwevu, ebomvu, eluhlaza okwesibhakabhaka, egolide.

Ukunyamezela

Amalungu anokuthi afakwe i-anodized ngemibala emininzi eyahlukeneyo-emnyama, ecacileyo, ebomvu, negolide.

Idyasi yomgubo

Amalungu anokuthi afakwe i-anodized ngemibala emininzi eyahlukeneyo-emnyama, ecacileyo, ebomvu, negolide.

I-CNC Machining Design Guidelines

| Uphawu | Inkcazo |

| Iifayili zekona zangaphakathi | Yila iifilathi zekona zangaphakathi zibe yi-0.020”-0.050” ezinkulu kunobungakanani obuqhelekileyo bokuqhuba kwiradiyi. Landela i-drill diameter ukuya kubunzulu bomlinganiselo we-1:6 (1:4 iyacetyiswa) njengesikhokelo kwikona yeradiyi yangaphakathi. |

| Iifillet zomgangatho | Yila iifayili zomgangatho ezincinci kuneefayili zekona ukuvumela isixhobo esifanayo ukuba sicoce izinto ezivela ngaphakathi. |

| Iindlela ezisezantsi | Ngalo lonke ixesha uyila ii-undercuts ukuya kwiisayizi eziqhelekileyo kwaye kude neekona ukuze zifikeleleke ngesixhobo sokusika. |

| Ubunzulu bomngxuma ocothiweyo/onomsonto | Nika isixhobo sokucocwa kancinane ngaphaya kobunzulu bomngxuma ocofayo ukuze uqinisekise imisonto epheleleyo. |

| Ukuntsonkotha | Gcina inani lokunqunyulwa okuncinci ukuya kubuncinci ukunciphisa iindleko ze-CNC zokwenza; yila kuphela kwiimpawu eziyimfuneko ukulungelelanisa umsebenzi kunye nobuhle. |

CNC Machining Tolerances

| Uphawu | Inkcazo |

| Ubungakanani beNdawo enkulu | Amalungu agayiweyo ukuya kuthi ga kwi-80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe amalungu ukuya kuthi ga kwi-62” (1,575 mm) ubude kunye ne-32” (813 mm) ububanzi. |

| Ixesha elimiselweyo lokukhokela | 3 iintsuku zokusebenza |

| Unyamezelo ngokubanzi | Ukunyamezela kwiintsimbi kuya kubanjwa ku- +/- 0.005 "(+/- 0.127 mm) ngokuhambelana ne-ISO 2768 ngaphandle kokuba kuchazwe ngenye indlela. Iiplastiki kunye ne-composites ziya kuba +/- 0.010 ". |

| Unyamezelo oluchanekileyo | I-FCE inokuvelisa kwaye ihlole ukunyamezelwa okuqinileyo ngokweenkcukacha zakho zomzobo kubandakanya i-GD&T callouts. |

| Ubuncinci bobungakanani boMsebenzi | 0.020” (0.50 mm) Oku kunokwahluka ngokuxhomekeke kwinxalenye yejometri nakwimathiriyeli ekhethiweyo. |

| Imisonto kunye neMingxunya eTapped | I-FCE inokuthatha nayiphi na isayizi yentambo eqhelekileyo. Singakwazi kwakhona umatshini imisonto yesiko; ezi ziya kufuna uphononongo lwesicatshulwa ngesandla. |

| Umda wemeko | Iincam ezibukhali zophulwe kwaye zigxothwe ngokungagqibekanga |

| Umphezulu Gqiba | Ukugqitywa okusemgangathweni kunjengoko-omatshini: 125 Ra okanye ngcono. Iinketho ezongezelelweyo zokugqiba zingachazwa xa ufumana isicatshulwa. |

Umgangatho Wesithembiso