Ekuleyibhelini kokungunda

CNC Machining Inkqubo ekhoyo

UbuNgcali bobuNjineli kunye nesiKhokelo

Iqela lobunjineli liya kukunceda ekwandiseni uyilo lwenxalenye yokubumba, ukujonga i-GD&T, ukukhetha izinto. I-100% iqinisekisa imveliso enokuveliswa okuphezulu, umgangatho, ukulandelwa

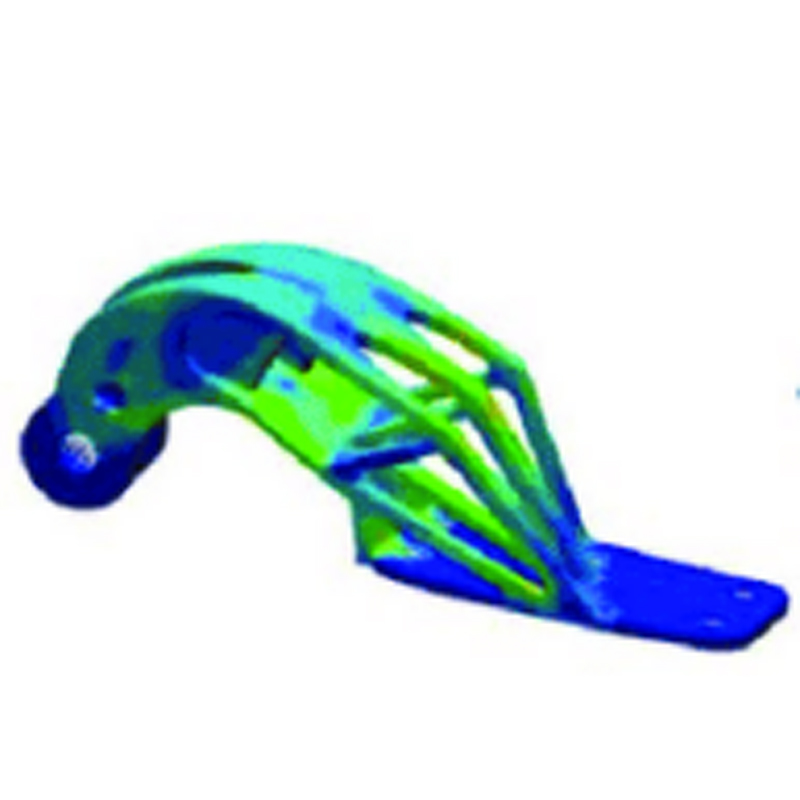

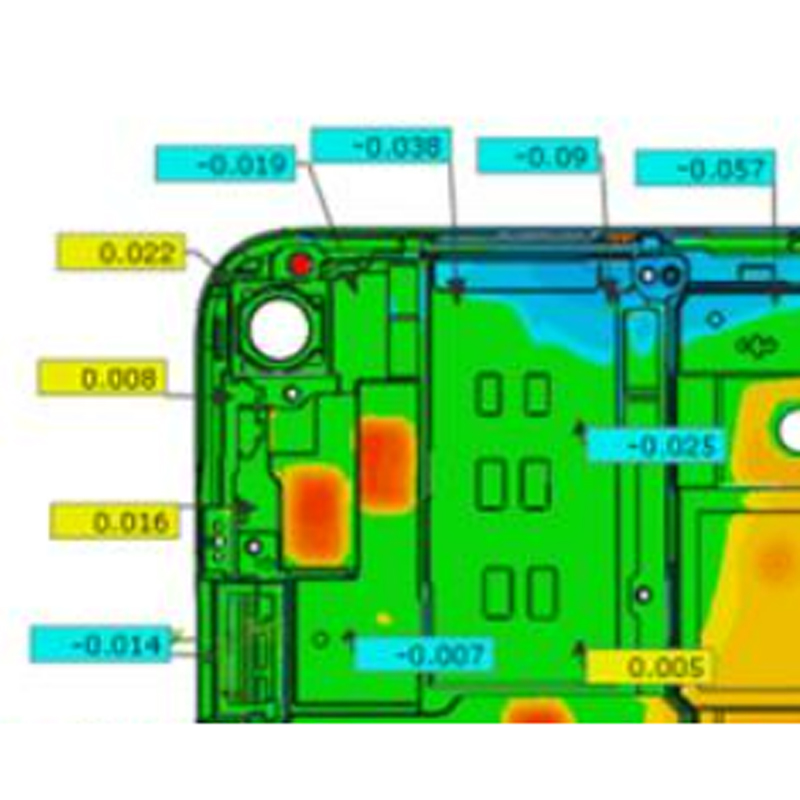

Ukulinganisa ngaphambi kokuSika iNsimbi

Kuqikelelo ngalunye, siya kusebenzisa i-mold-flow, iCreo, i-Mastercam ukulinganisa inkqubo yokubumba isitofu, inkqubo yomatshini, inkqubo yokuzoba ukuqikelela umba ngaphambi kokwenza iisampulu zomzimba.

Uyilo lweMveliso entsonkothileyo olwamkelweyo

Sinezona ndawo ziphezulu zokwenza ibhrendi ekubumbeni inaliti, umatshini weCNC kunye nokwenziwa kwentsimbi. Nto leyo evumela ukuba intsonkothile, imfuneko yoyilo lwemveliso oluchanekileyo

Kwinkqubo yendlu

Ukwenza i-injection mold, isitofu sokubumba kunye nenkqubo yesibini yoshicilelo lwepad, ubushushu bobushushu, isitampu esishushu, indibano zonke zisendlini, ke uya kuba neendleko eziphantsi kakhulu kunye nexesha elithembekileyo lophuhliso.

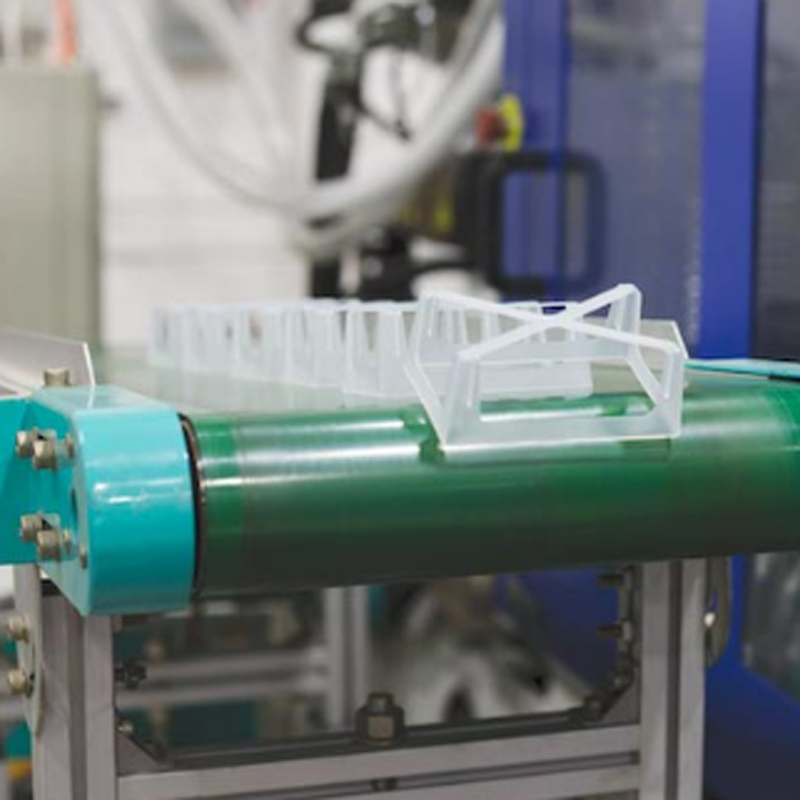

Ekuleyibhelini kokungunda

Kwi-Mold Labeling (IML) yinkqubo yokubumba isitofu apho uhombiso lwenxalenye yeplastiki, kusetyenziswa ileyibhile, iveliswa ngexesha lenkqubo yokutofa ngeplastiki. Ngamafutshane, ileyibhile eprintiweyo ifakwe ngokuzenzekela kumngxunya wesitofu sokungunda kwaye iplastiki itofwe ngaphezulu kwelebhile. Oku kuvelisa inxalenye yeplastiki ehonjisiweyo / "ebhalwe" apho ileyibhile idityaniswe ngokusisigxina kwindawo ngokwayo.

Uncedo lweendlela zokuleyibhela kwi-mold ye-Rosti ziquka:

• Ukuya kuthi ga kwi-45% igophe lefoyile (ubunzulu ukuya kububanzi)

• Inkqubo yasimahla eyomileyo nenyibilikayo

• Uyilo olungenamda olunokwenzeka

• Utshintsho loyilo olukhawulezayo

• Imifanekiso enezigqibo eziphezulu

• Amaxabiso aphantsi, ngakumbi kwiiprojekthi ezinomthamo ophezulu

• Ukuzuza iziphumo ezingenakwenzeka ngobunye ubugcisa

• Yomelele kwaye yomelele ekugcinweni okucocekileyo kweemveliso ezikhenkcezisiweyo nezefriji

• Ukugqitywa kokumelana nomonakalo

• Ukukhathalela indalo esingqongileyo

Izinto ezilungileyo ze-IML

Ezinye zezibonelelo zobugcisa ze-IML ziquka:

• Gqibezela umhlobiso wenxalenye ebunjiweyo

• Ukuqina kwemizobo: Iinki zikhuselwe yifilim kulwakhiwo lomphezulu wesibini

• Imisebenzi yesibini enxulumene nokuhombisa emva kokubumba iyapheliswa

• Ukupheliswa kwemfuno yeendawo zeelebhile ezihlaziyiweyo

• Iifilimu ezininzi kunye nolwakhiwo olukhoyo ukuhlangabezana neemfuno zabathengi

• Kulula ukuvelisa usetyenziso olunemibala emininzi

• Amazinga asezantsi ngokubanzi

• Ihlala ixesha elide kwaye ingaphazamiseki

• Ukulinganisa umbala ophezulu

• Akukho ndawo inokuqokelela ukungcola

• Imibala engenamkhawulo ekhoyo

KwiSicelo sokuLeyibhela uMngundo

Kuxhomekeke kakhulu kwintelekelelo yakho ukwenza isigqibo sokuba zeziphi iiprojekthi ezinokusebenzisa ukulebhelishwa komngundo, kodwa nazi iiprojekthi eziqhubekayo nezizayo;

- Izihluzi ze-tumbler ezomileyo, ukwenza i-automate kwinkqubo yokutya

- ukuphawulwa kweesirinji kunye neengqayi

- iikhowudi kunye namacandelo okumakisha kushishino lweemoto

-ukwenziwa kweemveliso kushishino lwamayeza njl.njl

-ukulandeleka kweemveliso ngeRFID

- ukuhombisa ngezinto ezingezizo eziqhelekileyo ezifana neempahla ezilukiweyo

Uluhlu lungenziwa ixesha elide kwaye ikamva liza kubonisa amatsha angekaviwa ngezicelo eziya kwenza imveliso ingabizi kwaye ikhawuleze, iphucule umgangatho kwaye iphucule ukhuseleko, ukulandeleka kunye nokusasazwa.

KwiMaterial yokuLeyibhela uMngundo

Ukunamathela phakathi kweefoyile ezahlukeneyo kunye nezixhobo ezigqithisayo

| Izinto ezigqithisiweyo | |||||||||||||||||

| ABS | NJENGE | EVA | PA6 | PA66 | PBT | PC | I-PEHD | PELD | I-PET | PMMA | I-POM | PP | PS-HI | SAN | TPU | ||

| Izinto zeFoil | ABS | ++ | + | + | + | + | − | − | + | + | − | − | ∗ | + | + | ||

| NJENGE | + | ++ | + | + | + | − | − | + | + | − | − | − | + | + | |||

| EVA | + | + | ++ | + | + | + | + | + | |||||||||

| PA6 | ++ | + | ∗ | ∗ | ∗ | ∗ | − | ∗ | − | + | + | ||||||

| PA66 | + | ++ | ∗ | ∗ | ∗ | ∗ | − | − | − | + | + | ||||||

| PBT | + | + | ∗ | ∗ | ++ | + | − | − | + | − | − | − | − | + | + | ||

| PC | + | + | ∗ | ∗ | + | ++ | − | − | + | + | − | − | − | + | + | ||

| I-PEHD | − | − | + | ∗ | ∗ | − | − | ++ | + | − | ∗ | ∗ | − | − | − | − | |

| PELD | − | − | + | ∗ | ∗ | − | − | + | ++ | − | ∗ | ∗ | + | − | − | − | |

| I-PET | + | + | + | + | − | − | + | − | − | − | + | ||||||

| PMMA | + | + | − | − | ∗ | ∗ | − | ++ | ∗ | − | + | ||||||

| I-POM | − | − | − | − | − | − | ∗ | ∗ | − | ++ | − | − | − | ||||

| PP | − | − | + | ∗ | − | − | − | − | + | ∗ | − | ++ | − | − | − | ||

| PS-HI | ∗ | − | + | − | − | − | − | − | − | − | − | − | − | ++ | − | − | |

| SAN | + | + | + | + | + | + | + | − | − | + | − | − | − | ++ | + | ||

| TPU | + | + | + | + | + | + | − | − | + | − | − | + | + | ||||

++ Ukuncamathela okugqwesileyo, + Ukuncamathela okulungileyo, ∗ Ukuncamathela okubuthathaka, − Akukho kuncamathela.

I-EVA, i-Ethylene vinyl acetate; PA6, Polyamide 6; PA66, Polyamide 66; PBT, Polybutylene terephthalate; PEHD, Polyethylene high density; I-PELD, i-Polyethylene yoxinaniso oluphantsi; I-POM, i-Polyoxymethylene; I-PS-HI, i-Polystyrene High Impact; SAN, iStyrene Acrylonitrile; TPU, Thermoplastic polyurethane.

Amandla ahambelanayo we-IML vs. IMD izisombululo zokulebula

Ukudibanisa inkqubo yokuhlobisa kunye nenkqubo yokubumba yongeza ukuqina, kunciphisa iindleko zokuvelisa kwaye kudala ukuguquguquka koyilo.

Ukuqina

Imizobo ayinakwenzeka ukususa ngaphandle kokutshabalalisa inxalenye yeplastiki kwaye iya kuhlala iphila ubomi benxalenye. Iinketho ziyafumaneka ukwenzela ukuqina okuphuculweyo kwiindawo ezirhabaxa kunye nokumelana neekhemikhali.

Ukusebenza kweendleko

I-IML iphelisa ukuleyibhelishwa kwasemva kokubumba, ukuphatha nokugcina. Iyanciphisa i-inventri ye-WIP kunye nexesha elongezelelweyo elifunekayo kwi-post-production decoration, kwi-site okanye ngaphandle kwendawo.

Ukuguquguquka koyilo

I-IML ifumaneka kuluhlu olubanzi lwemibala, iziphumo, ukuthungwa kunye nokukhethwa kwegraphic kwaye inokuphinda iphinde iphinde ibonakale inzima kakhulu njengensimbi engenasici, iinkozo zokhuni kunye ne-carbon fiber. Xa kufuneka isatifikethi se-UL, iisampuli zeleyibhile ezikwi-mold zivavanywa ngokuhambelana nemigangatho efanayo yokhuseleko esetyenziselwa ukuvavanya iilebhile ezibuthathaka.