Isevisi Yokubumba Umjovo

Ubungcweti Bobunjiniyela Nesiqondiso

Ithimba lobunjiniyela lizokusiza ekuthuthukiseni ukwakheka kwengxenye yokubumba, ukuhlola kwe-GD&T, ukukhetha kwezinto. I-100% iqinisekisa umkhiqizo ngokutholakala okuphezulu kokukhiqiza, ikhwalithi, ukulandeleka

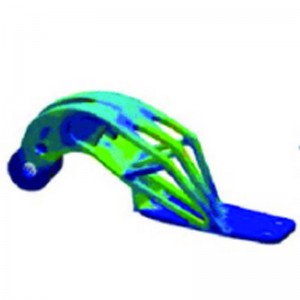

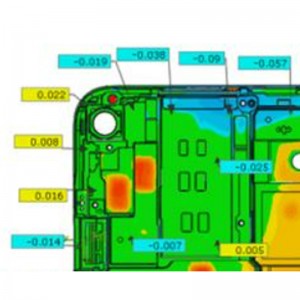

Ukulingisa ngaphambi kokusika insimbi

Ekuboneni ngakunye, sizosebenzisa ukugeleza kwesikhunta, i-Creo, i-Mastercam ukuze silingise inqubo yokubumba umjovo, inqubo yokwenza imishini, inqubo yokudweba ukubikezela inkinga ngaphambi kokwenza amasampula angokomzimba.

Ukwenziwa Komkhiqizo Okunembile

Sinezindawo eziphezulu zokukhiqiza umkhiqizo ekubunjweni komjovo, ukwenziwa kwemishini ye-CNC kanye nokwenza amashidi ensimbi. Okuvumela ukwakheka komkhiqizo okuyinkimbinkimbi, okunembayo okuphezulu

Enqubeni yasendlini

Ukwenza isikhunta somjovo, ukubumba komjovo kanye nenqubo yesibili yokuphrinta iphedi, ukugoba ukushisa, isitembu esishisayo, ukuhlanganisa konke kusendlini, ngakho-ke uzoba nezindleko eziphansi kakhulu nesikhathi sokuhola sokuthuthukiswa okuthembekile.

Inqubo Etholakalayo

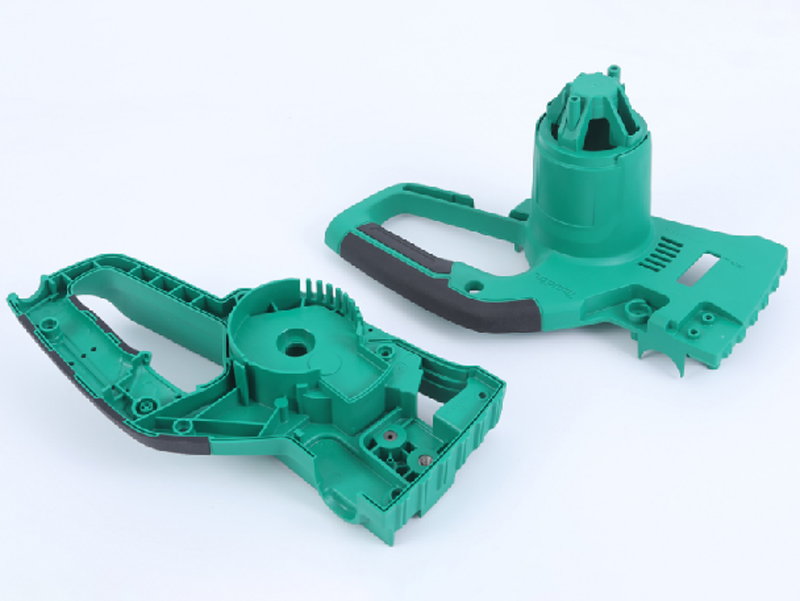

Overmolding

I-Overmolding ibizwa nangokuthi i-multi-k injection molding. kuyinqubo eyingqayizivele ehlanganisa izinto ezimbili noma eziningi, imibala ndawonye. Kuyindlela engcono kakhulu yokufinyelela umkhiqizo onemibala eminingi, ubulukhuni obuningi, ungqimba oluningi & umkhiqizo wokuthinta wokuthinta. Futhi isetshenziswe ekudubuleni okukodwa abe nomkhawulo ongakwazanga ukuzuzwa umkhiqizo.

Overmolding

I-Overmolding ibizwa nangokuthi i-multi-k injection molding. kuyinqubo eyingqayizivele ehlanganisa izinto ezimbili noma eziningi, imibala ndawonye. Kuyindlela engcono kakhulu yokufinyelela umkhiqizo onemibala eminingi, ubulukhuni obuningi, ungqimba oluningi & umkhiqizo wokuthinta wokuthinta. Futhi isetshenziswe ekudubuleni okukodwa abe nomkhawulo ongakwazanga ukuzuzwa umkhiqizo.

I-Liquid Silicone Rubber yokufaka umjovo

I-Liquid Silicone Rubber (LSR) iyindlela yokukhiqiza ye-Silicone enembayo ephezulu. Futhi kuwukuphela kwendlela yokuba nengxenye yerabha ecace kakhulu (esobala). Ingxenye ye-Silicone ihlala isikhathi eside ngisho naku-200degree temp. ukumelana kwamakhemikhali, impahla yebanga lokudla.

Emhlobiso wesikhunta

Kumhlobiso wesikhunta (IMD) kuyinqubo elula nephumelelayo. Ukuhlobisa kwenziwa ngaphakathi kwesikhunta ngaphandle kwenqubo yangaphambi / yesibili. Ukuhlobisa kuqediwe, kufaka phakathi ukuvikelwa kwejazi eliqinile, ngokubunjwa kwesibhamu esisodwa nje. Vumela umkhiqizo ube namaphethini angokwezifiso, isicwebezelisi nemibala.

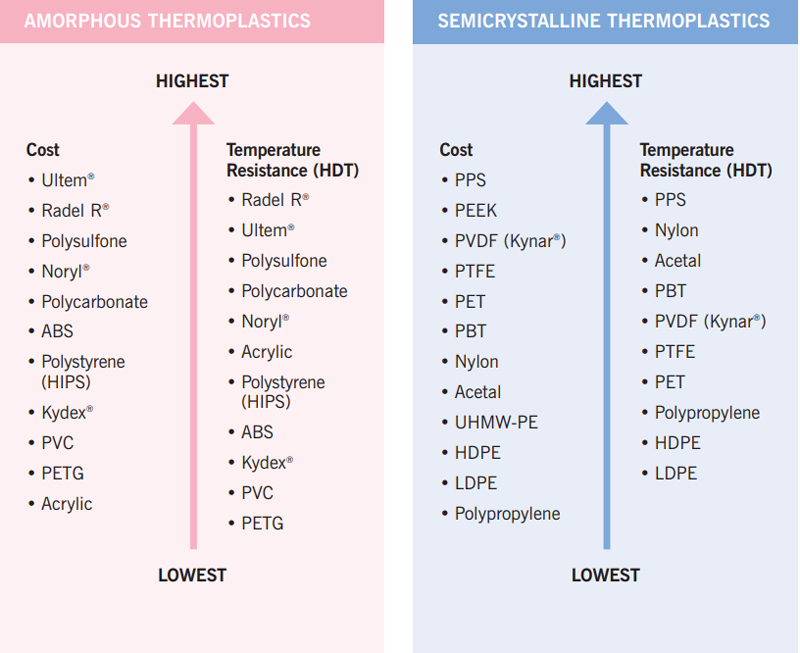

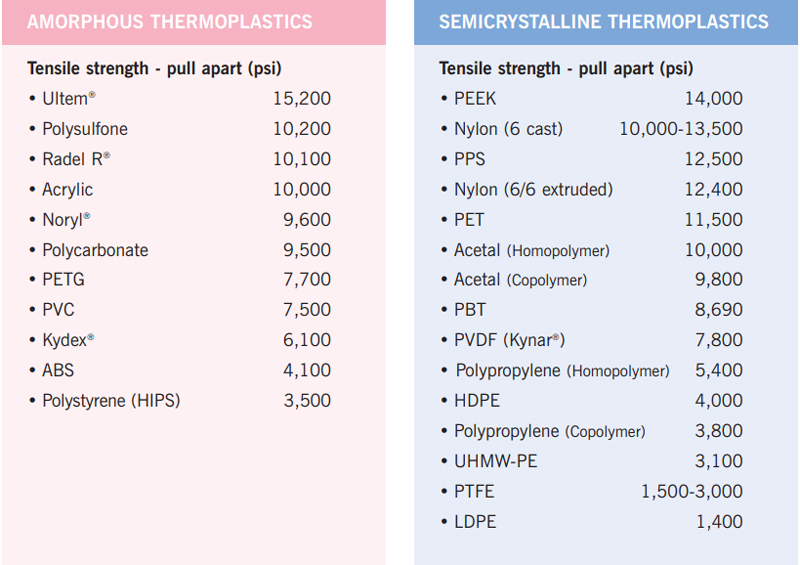

Ukukhetha Okubalulekile

I-FCE izokusiza ukuthi uthole izinto ezihamba phambili ngokuya ngesidingo somkhiqizo kanye nokusetshenziswa. Kunezinketho eziningi emakethe, sizophinde sihambisane nezindleko eziphumelelayo kanye nokuzinza kwe-supply chain ukuze sincome uhlobo kanye nebanga lama-resin.

Ingxenye ebunjiwe Iyaphela

| Iyacwebezela | I-Semi-Glossy | I-Matte | Ithunjiwe |

| I-SPI-A0 | I-SPI-B1 | I-SPI-C1 | I-MT (Moldtech) |

| I-SPI-A1 | I-SPI-B2 | I-SPI-C2 | I-VDI (Verein Deutscher Ingenieure) |

| I-SPI-A2 | I-SPI-B3 | I-SPI-C3 | YS (Yick Sang) |

| I-SPI-A3 |

I-Plastic Injection Molding Amakhono

Izinqubo Zesibili

Ukushisa Staking

Ukushisa bese Ucindezela okufakwayo kwensimbi noma enye ingxenye yento eqinile emkhiqizweni. Ngemva kokuba izinto ezincibilikayo seziqinile, zihlanganiswa ndawonye. Okujwayelekile kwamantongomane entambo yethusi.

I-Laser Engraving Maka amaphethini emkhiqizweni nge-laser. Nge-laser sensitive material, singaba ne-laser mark emhlophe engxenyeni emnyama.

Ukuphrinta kwephedi/ukuphrinta kwesikrini

Phrinta uyinki endaweni yomkhiqizo, ukuphrinta okunemibala eminingi kuyamukelwa.

I-NCVM kanye Nokupenda Ukuze ube nombala ohlukile, ubuhhadlahhadla, umphumela wensimbi kanye nomphumela wokulwa nokuklwebheka. Ngokujwayelekile emikhiqizweni yezimonyo.

I-Ultrasonic Plastic Welding

Hlanganisa izingxenye ezimbili ngamandla e-Ultrasonic, abiza ngempumelelo, uphawu oluhle kanye nezimonyo.

Izixazululo zokubumba ze-FCE Umjovo

Kusukela kumqondo kuya eqinisweni

Ithuluzi lesibonelo

Ukuze uthole ukuqinisekiswa kwedizayini esheshayo ngezinto zangempela nenqubo, ithuluzi lensimbi eliyisibonelo esisheshayo yisixazululo esihle sakho. Kungaba ibhuloho lokukhiqiza futhi.

- Awukho umkhawulo we-oda omncane

- Idizayini eyinkimbinkimbi iyafezeka

- Impilo yethuluzi lokudubula engu-20k iqinisekisiwe

Amathuluzi wokukhiqiza

Ngokujwayelekile ngensimbi eqinile, isistimu yomgijimi oshisayo, insimbi eqinile. Impilo yamathuluzi icishe ibe ngu-500k kuya ku-1million shot. Intengo yomkhiqizo weyunithi iphansi kakhulu, kodwa izindleko zokukhunta ziphezulu kunethuluzi lesibonelo

- Amashothi angaphezu kwesigidi

- Ukusebenza kahle okuphezulu nezindleko zokusebenzisa

- Ikhwalithi yomkhiqizo ephezulu

Inqubo Yokuthuthukiswa Okujwayelekile

Caphuna nge-DFx

Hlola idatha yakho yezidingo kanye nezinhlelo zokusebenza, unikeze izicaphuni zesimo ngeziphakamiso ezahlukahlukene. Umbiko wokulingisa uzonikezwa ngokuhambisana

Buyekeza i-prototype (okunye)

Dala ithuluzi elisheshayo (1~2wks) lokubumba amasampula esibonelo sokuklama nokuqinisekisa inqubo yokubumba

Ukuthuthukiswa kwesikhunta sokukhiqiza

Ungakhahlela irempu ngokushesha ngethuluzi le-prototype. Uma isidingo singaphezu kwezigidi, qalisa isikhunta sokukhiqiza nge-multi-cavitation ngokuhambisana, okuzothatha cishe. 2 ~ 5 amasonto

Phinda i-oda

Uma ugxile ekufuneni, singaqala ukulethwa zingakapheli izinsuku ezi-2. Alikho i-oda lokugxila, singakwazi ukuqala ukuthunyelwa okuncane njengezinsuku ezi-3

Q&A

Kuyini ukubumba umjovo?

Ukubumba komjovo amahhafu amabili esikhunta sensimbi amakhulu ahlangana ndawonye, ipulasitiki noma impahla yerabha ijovwa emgodini. Izinto zepulasitiki ezijovwayo ziyancibilika, azishisi ngempela; Impahla icindezelwa kumjovo ngesango lomgijimi. Njengoba impahla icindezelwa, iyashisa futhi iqala ukugeleza esikhunjeni. Uma selipholile, izingxenye ezimbili ziyahlukana futhi ingxenye iyaphuma. Phinda izenzo ezifanayo ekuvaleni isikhunta futhi uvule isikhunta njengesiyingi esisodwa, futhi usunezingxenye ezibunjiwe zomjovo sezilungile.

Yiziphi izimboni ezisebenzisa umjovo wokubumba?

Izinkambu ezihlukahlukene zingasetshenziswa kulokhu okulandelayo:

Ezokwelapha Nezemithi

Ezogesi

Ukwakha

Ukudla Nesiphuzo

Ezezimoto

Amathoyizi

Izimpahla Zabathengi

Umndeni

Yiziphi izinhlobo zezinqubo zokubumba umjovo?

Kunezinhlobo eziningana zezinqubo zokubumba umjovo, okuhlanganisa:

Ukubunjwa komjovo wepulasitiki ngokwezifiso

Overmolding

Faka ukubumba

Ukubumba umjovo osizwa ngegesi

Ukubumba komjovo werabha ye-silicone ewuketshezi

Ukubumba umjovo wensimbi

Ukubunjwa komjovo wokusabela

Isikhunta somjovo sihlala isikhathi esingakanani?

Kuncike ezintweni ezimbalwa: okokusebenza kwesikhunta, inani lemijikelezo, izimo zokusebenza, kanye nesikhathi sokupholisa/ sokubamba ingcindezi phakathi kokuqalisa kokukhiqiza.

Uyini umehluko phakathi kokubumba nokubumba?

Nakuba kufana kakhulu, umehluko phakathi kokwenza nokubumba wehlela ezicini zakho ezihlukile kanye nezinzuzo, kuya ngesicelo ezisetshenziselwa sona. Ukubumba umjovo kufaneleka kakhulu emiqhudelwaneni emikhulu yokukhiqiza. I-Thermoforming, ifaneleka kakhulu ekukhiqizeni okufushane okugijima kwemiklamo emikhulu futhi kuhilela ukwenza amashidi epulasitiki ashisayo ebusweni besikhunta.