Isevisi Yokwenziwa Kwensimbi Yangokwezifiso

Izithonjana

Usekelo lobunjiniyela

Ithimba lonjiniyela lizokwabelana ngolwazi lwalo, lisize engxenyeni yokwenza kahle kwedizayini, ukuhlola kwe-GD&T, ukukhetha izinto ezibonakalayo. Qinisekisa ukuthi kungenzeka umkhiqizo kanye nekhwalithi

Ukulethwa Okusheshayo

Izinto ezivamile ezingaphezu kuka-5000+ esitokweni, imishini engu-40+ ukusekela isidingo sakho esiphuthumayo. Ukulethwa kwesampula okuncane njengosuku olulodwa

Yamukela umklamo oyinkimbinkimbi

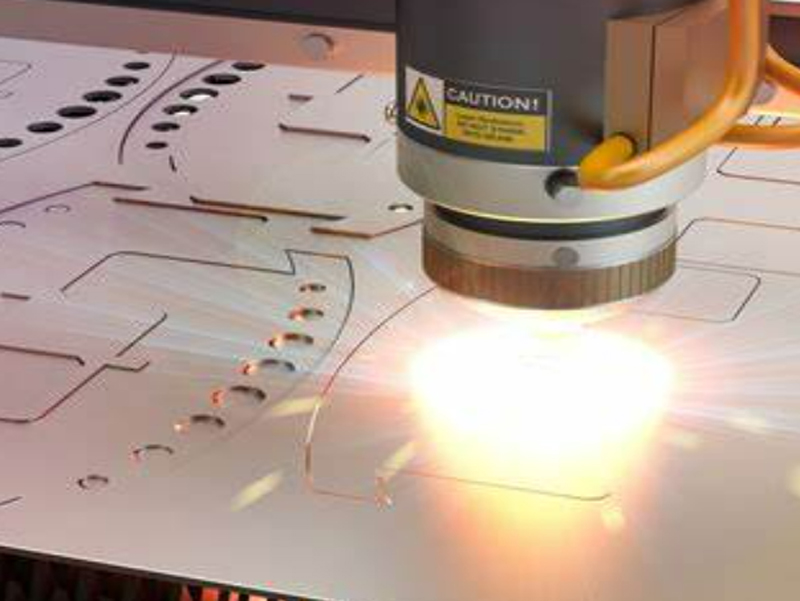

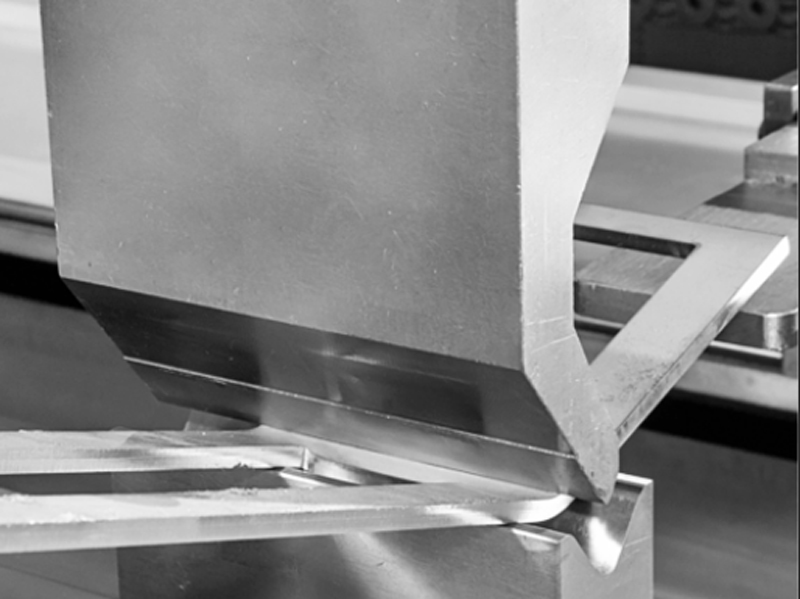

Sinezindawo eziphezulu zokusika i-laser, ukugoba, ukushisela okuzenzakalelayo kanye nokuhlola. Okuvumela ukwakheka komkhiqizo okuyinkimbinkimbi, okunembayo okuphezulu

Inqubo yendlu yesi-2

Ukumbozwa ngempushana okunemibala ehlukene nokukhanya, ukuphrinta kwephedi/isikrini kanye nokugxiviza okushisayo kwezimpawu, i-riveting kanye nokushisela ukuhlanganiswa kwebhokisi lokwakha

Izinzuzo ze-FCE Sheet metal

Ifektri yethu ihlomele imishini yobuchwepheshe ehamba phambili yokwenza amashidi ensimbi. Ukusika kwe-laser yesinxephezelo esinamandla, imishini yokukhipha unqenqema oluzenzakalelayo, imishini yokugoba enembile ye-CNC. Kuqinisekisiwe ukubekezelelana kokukhiqiza okungcono kakhulu.

Ukubekezelelana Okuqinile Kwamukelwe

I-FCE yahlola futhi yamisa isisekelo sedatha yepharamitha yokusika i-laser yezinto ezihlukile. Singenza ukunemba okungcono kakhulu kokukhiqiza ekukhiqizeni kokuqala.

| US | Imethrikhi | |

| Ukugoba | +/- 0.5 degree | +/- 0.5 degree |

| Ama-Offsets | +/- 0.006 in. | +/- 0.152mm |

| I-Hole Diameters | +/- 0.003 in. | +/- 0.063mm |

| Umphetho ukuya onqenqemeni/umgodi; umgodi ukuya emgodini | +/- 0.003 in. | +/- 0. 063mm |

| I-Hardware emaphethelweni/embobeni | +/- 0.005 in. | +/- 0.127mm |

| Hardware kuya hardware | +/- 0.007 in. | +/- 0.191mm |

| Gobela onqenqemeni | +/- 0.005 in. | +/- 0.127mm |

| Gobela emgodini/i-hardware/goba | +/- 0.007 in. | +/- 0.191mm |

Unqenqema olucijile lususiwe

Wena kanye namakolishi akho ningase nihlale nilinyazwa unqenqema olucijile lweshidi lensimbi. Okwengxenye abantu abahlale beyithinta, i-FCE ikunikeza imikhiqizo ecijile ngokuphelele ekhishiwe.

Ihlanzekile futhi ayinakuklwebha

Ngomkhiqizo odingeka kakhulu wezimonyo, sivikela indawo engaphezulu ngokunamathisela amafilimu kuyo yonke inqubo, siyikhumule lapho ekugcineni sipakisha umkhiqizo.

Sheet Metal Process

I-FCE edidiyelwe yokusika i-laser, ukugoba kwe-CNC, ukubhoboza kwe-CNC, ukushisela, i-riveting kanye nenqubo yokuhlobisa indawo endaweni yokusebenzela eyodwa. Ungathola umkhiqizo ophelele ngekhwalithi ephezulu nesikhathi sokuhola esifushane kakhulu.

Ukusika i-laser

Ubukhulu Ubukhulu: Kufika ku-4000 x 6000 mm

Ubukhulu obukhulu: Kufika ku-50 mm

Ukuphindaphinda: +/- 0.02 mm

Ukunemba kwesikhundla: +/- 0.05 mm

Ukugoba

Amandla: Kufika kumathani angama-200

Ubude obukhulu: Kufika ku-4000 mm

Ubukhulu obukhulu: Kufika ku-20 mm

CNC isibhakela

Usayizi wokucubungula ophezulu: 5000 * 1250mm

Ubukhulu obukhulu: 8.35 mm

Ubukhulu bokubhoboza idaya: 88.9 mm

I-Riveting

Ubukhulu Ubukhulu: Kufika ku-4000 x 6000 mm

Ubukhulu obukhulu: Kufika ku-50 mm

Ukuphindaphinda: +/- 0.02 mm

Ukunemba kwesikhundla: +/- 0.05 mm

Ukugxiviza

Ithoni: 50 ~ 300 Ton

Ubukhulu bengxenye yosayizi: 880 mm x 400 mm

Ukushisela

Uhlobo lwe-Welding: I-Arc, i-Laser, i-Resistance

Ukusebenza: Manual kanye Automation

Izinto Ezitholakalayo zokwenza amashidi ensimbi

I-FCE ilungiselele impahla yeshidi evamile engu-1000+ esitokweni ukuze iguqulwe ngokushesha, Ubunjiniyela bethu bokusebenza buzokusiza ekukhetheni izinto ezibonakalayo, ukuhlaziya ngomshini, ukwenziwa ngcono.

| I-Aluminium | Ithusi | Ibhulonzi | Insimbi |

| I-Aluminium 5052 | Ithusi 101 | I-Bronze 220 | Insimbi Engagqwali 301 |

| I-Aluminium 6061 | I-Copper 260 (Ithusi) | Ibhulonzi 510 | Insimbi Engagqwali 304 |

| Ithusi C110 | Insimbi Engagqwali 316/316L | ||

| Insimbi, Ikhabhoni Ephansi |

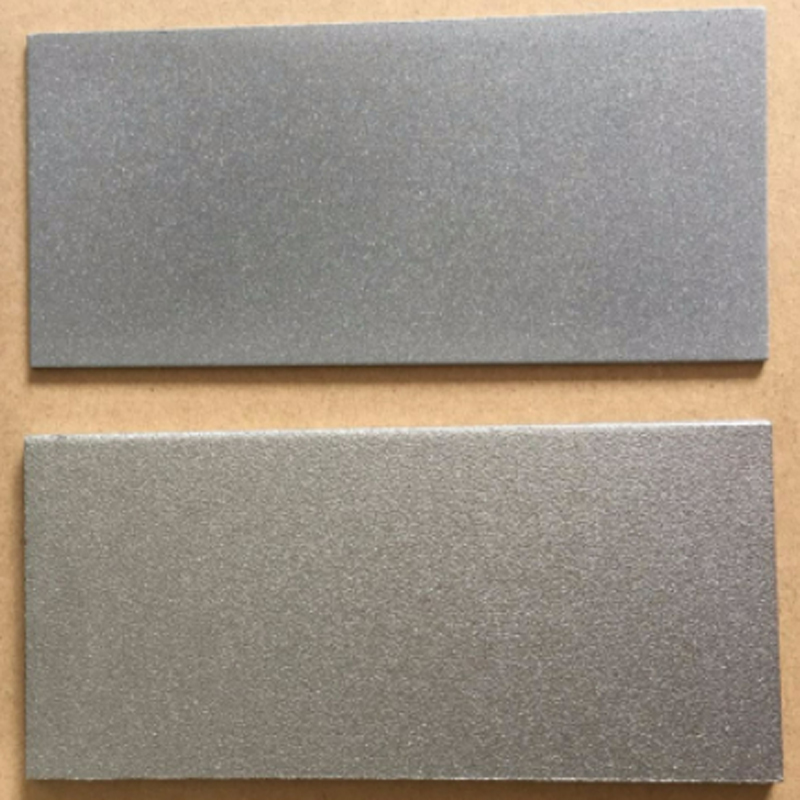

I-Surface Finish

I-FCE inikeza uhla oluphelele lwezinqubo zokwelashwa kwendawo. I-Electroplating, i-powder coating, i-anodizing ingenziwa ngezifiso ngokuya ngombala, ukuthungwa nokukhanya. Isiphetho esifanele singabuye sinconywe ngokuvumelana nezidingo zokusebenza.

Ukuxubha

Ukuqhuma

Ukupholisha

I-anodizing

I-Powder Coating

Ukudlulisa Okushisayo

Ukucwenga

Ukuphrinta & Laser Mark

Isethembiso Sethu Sekhwalithi

Imibuzo Evame Ukubuzwa

Iyini I-Sheet Metal Fabrication?

Ukwenziwa kwensimbi yeshidi kuyinqubo yokukhiqiza ekhiphayo esika noma/futhi yakhe izingxenye ngamashidi ensimbi. Izingxenye zensimbi zeshidi zazivame ukusetshenziselwa isidingo sokunemba nokuqina okuphezulu, izinhlelo zokusebenza ezijwayelekile i-chassis, izivalo, nabakaki.

Iyini i-Sheet Metal Forming?

Izinqubo zokwenza insimbi yeshidi yilezo lapho amandla asetshenziswa eshidini lensimbi ukuze kulungiswe isimo sayo kunokususa noma iyiphi into. Amandla asetshenziswayo agcizelela insimbi ngaphezu kwamandla ayo okukhiqiza, okwenza ukuthi impahla ikhubazeke ngokwepulasitiki, kodwa ingaphuli. Ngemuva kokukhishwa kwamandla, ishidi lizobuyela emuva kancane, kodwa ngokuyisisekelo ligcine imimo njengoba icindezelwe.

Kuyini ukugxiviza kwensimbi?

Ukwandisa ukusebenza kahle kokukhiqizwa kwensimbi, i-Metal stamping die isetshenziselwa ukuguqula amashidi ensimbi ayisicaba abe yizimo ezithile. Kuyinqubo eyinkimbinkimbi engahlanganisa inqwaba yamasu okwenza insimbi - ukuvala, ukubhoboza, ukugoba nokubhoboza.

Ithini isikhathi sokukhokha?

Ikhasimende elisha, u-30% wokukhokha kusengaphambili. Linganisa okusele ngaphambi kokuthumela umkhiqizo ngomkhumbi. I-oda elivamile, samukela isikhathi sokukhokha sezinyanga ezintathu