I-Custom Sheet Metal Forming

Izithonjana

Usekelo lobunjiniyela

Ithimba lonjiniyela lizokwabelana ngolwazi lwalo, lisize engxenyeni yokwenza kahle kwedizayini, ukuhlola kwe-GD&T, ukukhetha izinto ezibonakalayo. Qinisekisa ukuthi kungenzeka umkhiqizo kanye nekhwalithi

Ukulethwa Okusheshayo

Izinto ezivamile ezingaphezu kuka-5000+ esitokweni, imishini engu-40+ ukusekela isidingo sakho esiphuthumayo. Ukulethwa kwesampula okuncane njengosuku olulodwa

Yamukela umklamo oyinkimbinkimbi

Sinezindawo eziphezulu zokusika i-laser, ukugoba, ukushisela okuzenzakalelayo kanye nokuhlola. Okuvumela ukwakheka komkhiqizo okuyinkimbinkimbi, okunembayo okuphezulu

Inqubo yendlu yesi-2

Ukumbozwa ngempushana okunemibala ehlukene nokukhanya, ukuphrinta kwephedi/isikrini kanye nokugxiviza okushisayo kwezimpawu, i-riveting kanye nokushisela ukuhlanganiswa kwebhokisi lokwakha

Sheet Metal Process

I-FCE sheet metal forming service edidiyelwe yokugoba, ukwenza ama-roll, ukudweba okujulile, izinqubo zokwakheka ezinwebeka endaweni yokusebenzela eyodwa. Ungathola umkhiqizo ophelele ngekhwalithi ephezulu nesikhathi sokuhola esifushane kakhulu.

Ukugoba

Ukugoba kuyinqubo yokwenza insimbi lapho amandla asetshenziswa ocezwini lweshidi lensimbi, okubangela ukuba ligobe nge-engeli bese lenza umumo oyifunayo. Umsebenzi wokugoba udala ukuwohloka ku-eksisi eyodwa, kodwa ukulandelana kwemisebenzi eminingana ehlukene kungenziwa ukuze kwakhiwe ingxenye eyinkimbinkimbi. Izingxenye ezigobile zingaba zincane kakhulu, njengabakaki, njengendawo ebiyelwe enkulu noma i-chassis

Ukwakhiwa kweroli

Ukwakhiwa kwamarola, kuyinqubo yokwakha insimbi lapho ishidi lensimbi lilolongwa ngokuqhubekayo ngochungechunge lwemisebenzi yokugoba. Inqubo yenziwa emgqeni wokwenza umqulu. Isiteshi ngasinye sinerola, ebizwa ngokuthi i-roller die, ebekwe nhlangothi zombili zeshidi. Umumo nosayizi we-roller die kungase kuhluke kuleso siteshi, noma ama-roller amaningi afanayo afa angasetshenziswa ezindaweni ezihlukene. I-roller dies ingaba ngaphezulu nangaphansi kweshidi, eduze nezinhlangothi, nge-engeli, njll. i-roller dies igcotshwa ukuze kuncishiswe ukungqubuzana phakathi kwe-dies and sheet, ngaleyo ndlela kuncishiswe ukuguga kwethuluzi.

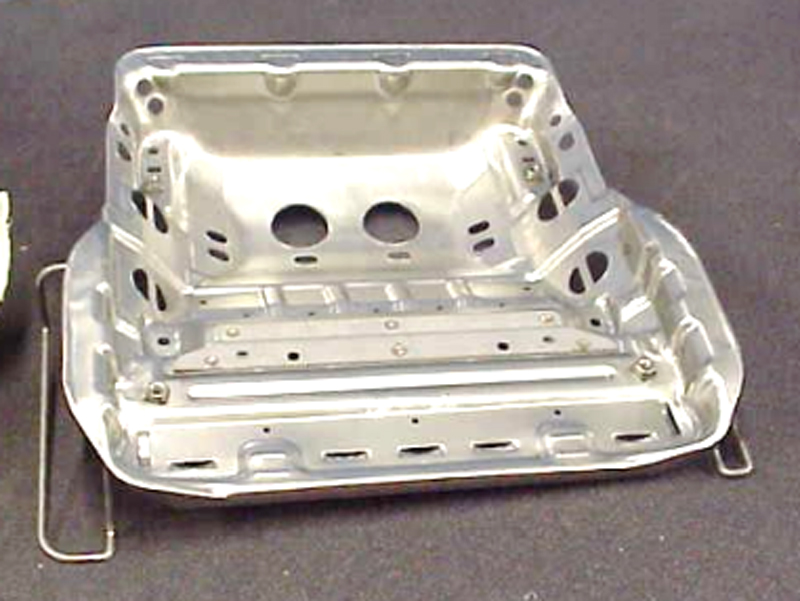

Umdwebo ojulile

Ukudweba okujulile kuyinqubo yokwenza insimbi yeshidi lapho insimbi yensimbi yakheka khona ibe ingxenye oyifunayo ngethuluzi lokudweba. Ithuluzi lesilisa liphushela insimbi yeshidi liye phansi libe imbobo esesimweni sengxenye yomklamo. Amandla aqinile asetshenziswa eshidini lensimbi abangela ukuba liguge libe ingxenye emise okwenkomishi. Umdwebo ojulile usetshenziswa kakhulu ngezinsimbi ze-ductile, njenge-aluminium, ithusi, ithusi, nensimbi ethambile. Uhlelo lokusebenza olujwayelekile lokudweba okujulile yimizimba yezimoto namathangi kaphethiloli, amathini, izinkomishi, osinki basekhishini, amabhodwe namapani.

Umdwebo Wezimo Eziyinkimbinkimbi

Ngaphandle kokudweba okujulile, i-FCE iphinde ibe nesipiliyoni sokukhiqiza insimbi eyinkimbinkimbi. Ukuhlaziywa kwesici esiphelile ukusiza ukuthola ingxenye yekhwalithi enhle esivivinyweni sokuqala.

Uku-ayina

Ishidi lensimbi linga-ayinwa ukuze kutholakale ukushuba okufanayo. Isibonelo, ngale nqubo ungenza umkhiqizo ube mncane kakhulu odongeni oluseceleni. Kodwa okujiyile phansi. Isicelo esijwayelekile ngamathini, izinkomishi.

Izinto Ezitholakalayo zokwenza amashidi ensimbi

I-FCE ilungiselele impahla yeshidi evamile engu-1000+ esitokweni ukuze iguqulwe ngokushesha, Ubunjiniyela bethu bokusebenza buzokusiza ekukhetheni izinto ezibonakalayo, ukuhlaziya ngomshini, ukwenziwa ngcono.

| I-Aluminium | Ithusi | Ibhulonzi | Insimbi |

| I-Aluminium 5052 | Ithusi 101 | I-Bronze 220 | Insimbi Engagqwali 301 |

| I-Aluminium 6061 | I-Copper 260 (Ithusi) | Ibhulonzi 510 | Insimbi Engagqwali 304 |

| Ithusi C110 | Insimbi Engagqwali 316/316L | ||

| Insimbi, Ikhabhoni Ephansi |

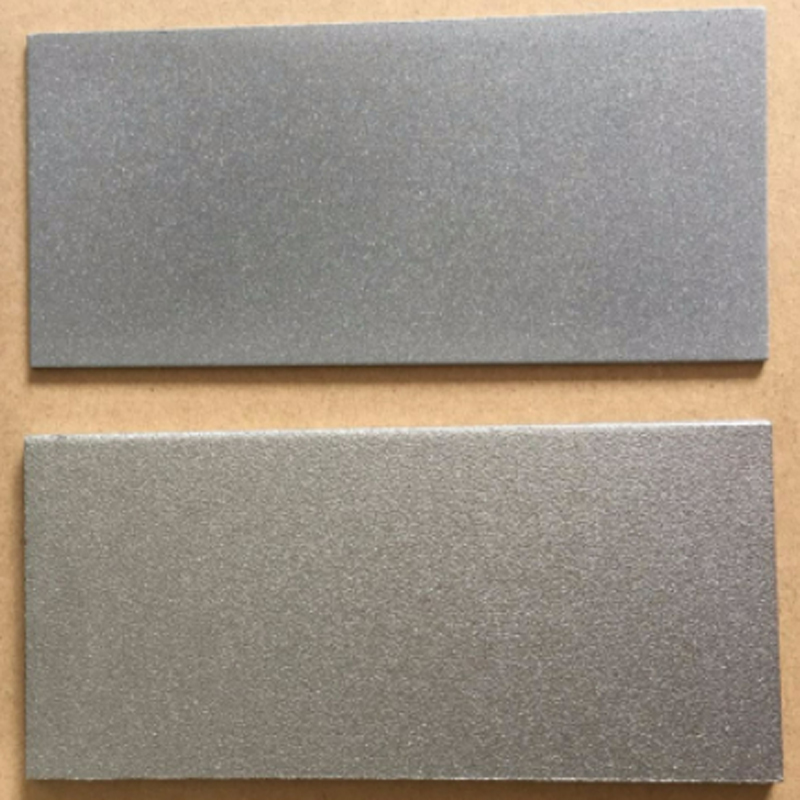

I-Surface Finish

I-FCE inikeza uhla oluphelele lwezinqubo zokwelashwa kwendawo. I-Electroplating, i-powder coating, i-anodizing ingenziwa ngezifiso ngokuya ngombala, ukuthungwa nokukhanya. Isiphetho esifanele singabuye sinconywe ngokuvumelana nezidingo zokusebenza.

Ukuxubha

Ukuqhuma

Ukupholisha

I-anodizing

I-Powder Coating

Ukudlulisa Okushisayo

Ukucwenga

Ukuphrinta & Laser Mark

Isethembiso Sethu Sekhwalithi

Imibuzo Evame Ukubuzwa

Iyini I-Sheet Metal Fabrication?

Ukwenziwa kwensimbi yeshidi kuyinqubo yokukhiqiza ekhiphayo esika noma/futhi yakhe izingxenye ngamashidi ensimbi. Izingxenye zensimbi zeshidi zazivame ukusetshenziselwa isidingo sokunemba nokuqina okuphezulu, izinhlelo zokusebenza ezijwayelekile i-chassis, izivalo, nabakaki.

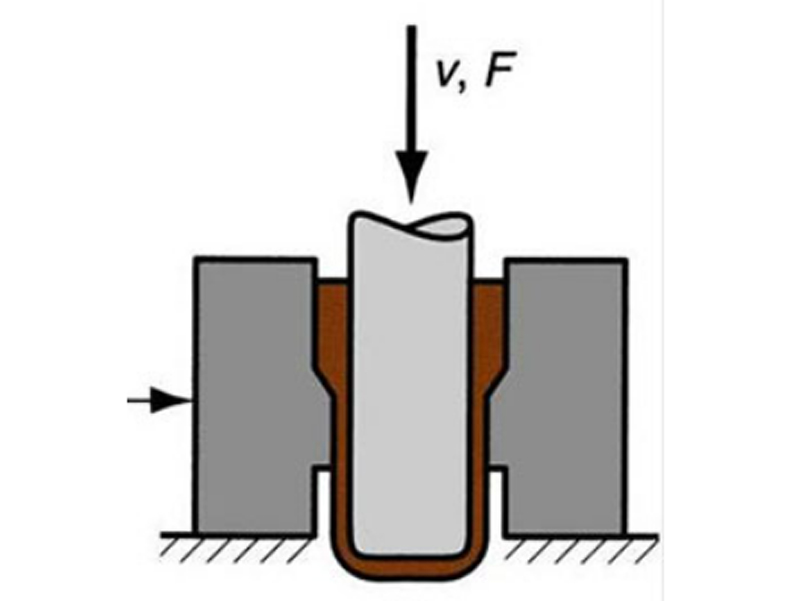

Iyini i-Sheet Metal Forming?

Izinqubo zokwenza insimbi yeshidi yilezo lapho amandla asetshenziswa eshidini lensimbi ukuze kulungiswe isimo sayo kunokususa noma iyiphi into. Amandla asetshenziswayo agcizelela insimbi ngaphezu kwamandla ayo okukhiqiza, okwenza ukuthi impahla ikhubazeke ngokwepulasitiki, kodwa ingaphuli. Ngemuva kokukhishwa kwamandla, ishidi lizobuyela emuva kancane, kodwa ngokuyisisekelo ligcine imimo njengoba icindezelwe.

Kuyini ukugxiviza kwensimbi?

Ukwandisa ukusebenza kahle kokukhiqizwa kwensimbi, i-Metal stamping die isetshenziselwa ukuguqula amashidi ensimbi ayisicaba abe yizimo ezithile. Kuyinqubo eyinkimbinkimbi engahlanganisa inqwaba yamasu okwenza insimbi - ukuvala, ukubhoboza, ukugoba nokubhoboza.

Ithini isikhathi sokukhokha?

Ikhasimende elisha, u-30% wokukhokha kusengaphambili. Linganisa okusele ngaphambi kokuthumela umkhiqizo ngomkhumbi. I-oda elivamile, samukela isikhathi sokukhokha sezinyanga ezintathu