Isevisi yokuphrinta ye-3D

Izilinganiso Ezisheshayo kanye Nempendulo Yokwenzeka Kwezokukhiqiza

Ngithumelele imodeli yakho yokuklama ukuze uthole inani elisheshayo futhi ngikhiqize impendulo engenzeka, ulwazi oluningi ukuze ngikubuyisele inani elincintisanayo

Isampula ephrintiwe ngokushesha ukusuka ku-Prototype kuya Ekukhiqizeni

Insiza yamandla esheshayo futhi egcwele ukuze ihlangabezane nemfuneko yakho kungakhathaliseki ukuthi yisiphi isikhathi noma isidingo soku-oda kusuka ku-prototype kuya ekukhiqizeni

Ukulandelela i-oda nokulawulwa kwekhwalithi

Ungalokothi ukhathazeke ukuthi izingxenye zakho ziphi, isibuyekezo sesimo sansuku zonke esinevidiyo nezithombe singaqinisekisa ukuthi uhlale ugxile kukho. Isikhathi sangempela sokukubonisa ingxenye yekhwalithi ukuthi iyini

Inqubo yendlu yesi-2

Ukupenda kwemibala ehlukene nokukhanya, ukuphrinta kwephedi noma ukufaka ukubumba kanye nokuhlanganiswa okuncane okufana ne-silicon kungasetshenziswa

Izinqubo eziningi zokuphrinta ezingaphansi kwe-3D zisetshenziswa esitshalweni sethu maqondana nezinto zepulasitiki nezensimbi. Inketho ngayinye ehlongozwayo esebenzayo yokonga izindleko nokuqinisekiswa kokusebenza kuphezu kwemfuneko yakho.

Izithombe

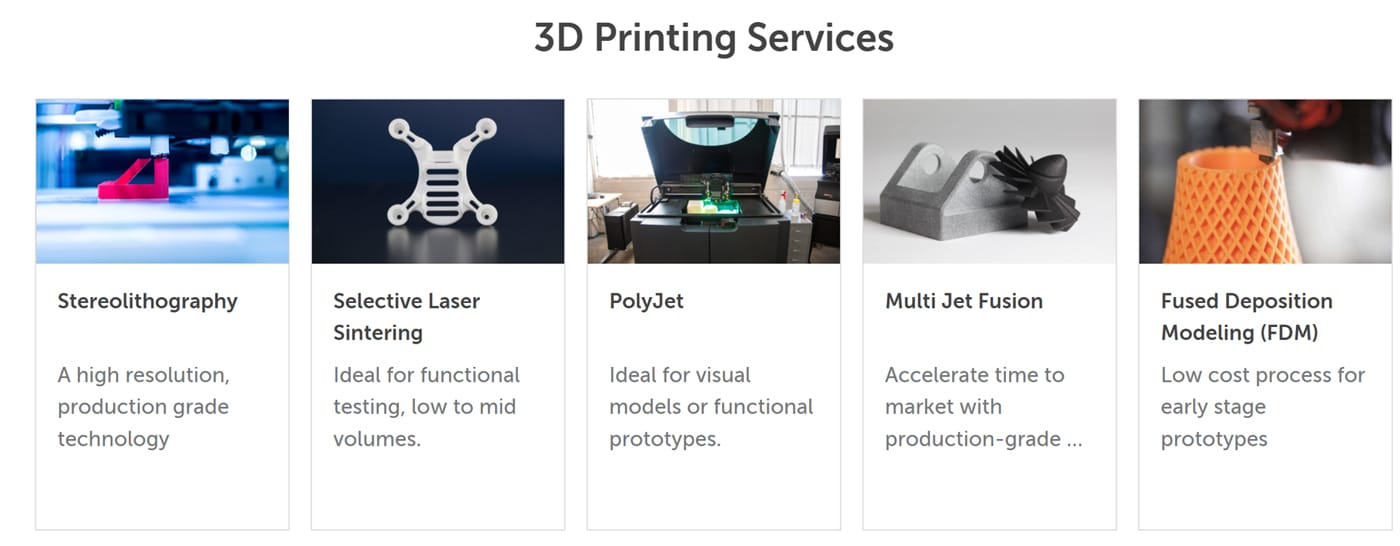

I-FDM (Fused Deposition Modeling)

Inqubo yokuphrinta yezindleko eziphansi yokubuyekezwa kwesibonelo sangaphambilini Induku yocingo njengento eyisisekelo

I-SLA (Stereolithography)

Inqubo ebanzi yezinga elingcono lendawo kanye nezinga lokukhiqiza

I-SLS (I-Selective Laser Sintering)

Inketho yokuqinisekisa efiselekayo enesidingo sevolumu ephansi noma emaphakathi

I-PolyJet

Inketho efiselekayo yamamodeli wokuqinisekisa abonakalayo nokusebenzayo

Ukuqhathaniswa Kwenqubo Yokuphrinta ye-3D

| Igama Lesakhiwo | I-Fused Deposition Modeling | I-Stereolithography | I-Laser Sintering ekhethiwe |

| Isifinyezo | I-FDM | I-SLA | I-SLS |

| Uhlobo lwezinto | Okuqinile (Imicu) | Uketshezi (Photopolymer) | Impuphu (Polymer) |

| Izinto zokwakha | I-Thermoplastics efana ne-ABS, i-Polycarbonate, ne-Polyphenylsulfone; Ama-elastomers | I-Thermoplastics (Elastomers) | I-Thermoplastics efana ne-nylon, i-Polyamide, ne-Polystyrene; Ama-elastomers; Izinhlanganisela |

| Ubukhulu bengxenye kasayizi (in.) | 36.00 x 24.00 x 36.00 | 59.00 x 29.50 x 19.70 | 22.00 x 22.00 x 30.00 |

| Usayizi omncane wesici (in.) | 0.005 | 0.004 | 0.005 |

| Ubukhulu besendlalelo esincane (in.) | 0.0050 | 0.0010 | 0.0040 |

| Ukubekezelelana (in.) | ±0.0050 | ±0.0050 | ±0.0100 |

| Ukuqedwa kobuso | Kunzima | Bushelelezi | Isilinganiso |

| Yakha isivinini | Kancane | Isilinganiso | Ngokushesha |

| Izinhlelo zokusebenza | I-prototyping esheshayo ebiza kancane Amamodeli ayisisekelo wobufakazi bomqondo Khetha izingxenye ezisetshenziswa ekugcineni ezinemishini yezimboni esezingeni eliphezulu nezinto zokwakha. | Ukuhlolwa kwefomu/ukufaneleka, Ukuhlola okusebenzayo, Amaphethini wamathuluzi asheshayo, Ukulingana kwe-Snap, Izingxenye ezinemininingwane eminingi, Amamodeli ezethulo, Izinhlelo zokusebenza zokushisa okuphezulu | Ukuhlola amafomu/ukufaneleka, Ukuhlola okusebenzayo, Amaphethini wamathuluzi asheshayo, Izingxenye ezinemininingwane encane, Izingxenye ezinama-snap-fits namahinge aphilayo, Ukushisa okuphezulu |

Izinto Zokuphrinta ze-3D

I-ABS

Impahla ye-ABS iyipulasitiki enhle enamandla aqinile okuqinisekiswa kwe-prototype emangelengele ekuqaleni. Ingapholishwa kalula ukuze iqedele indawo ecwebezelayo

Imibala: Okumnyama, okumhlophe, Okungafihli

Okungcono kakhulu:

- Ibheke ukudala ukuphrinta okunzima, okumazombezombe noma okupholisekayo ngokuqedwa okucwebezelayo

- Ochwepheshe abafuna izindleko eziphansi kodwa ngama-prototypes anamandla aphezulu

I-PLA

I-PLA iphrinta ekushiseni okuphansi, futhi inamathela kahle kumbhede wokuphrinta. Ngenxa yokuthi lesi sici sishibhile uma kuqhathaniswa, ungabiza ngempumelelo ukuphrinta kwe-3D ukuphindaphinda okuningi komklamo wengxenye yasekuqaleni.

Imibala: Ingathathi hlangothi, emhlophe, emnyama, eluhlaza okwesibhakabhaka, ebomvu, ewolintshi, eluhlaza, epinki, e-aqua

Kuhle kakhulu

- Ubani ofuna ukuphrinta kwe-3D ngaphandle kwengcindezi

- Ongenandaba nezinga lokushisa eliphezulu noma izingxenye zokumelana nomthelela

- Ochwepheshe abafuna ukulingisa ngeshibhile nangempumelelo

I-PETG

I-PETG iyindawo ephakathi efinyelelekayo phakathi kwe-ABS ne-PLA. Inamandla kune-PLA, futhi i-warps ngaphansi kwe-ABS, futhi inikeza okunye okunamathelayo kwesendlalelo okungcono kakhulu kwanoma iyiphi imicu yokuphrinta ye-3D.

Imibala: Okumnyama, okumhlophe, Okungafihli

Okungcono kakhulu:

- Obani abathokozela isiphetho esicwebezelayo se-PETG

- Othile ofuna ukusizakala ngemvelo ye-PETG ephephile futhi engangeni manzi

I-TPU/Silicone

I-TPU ayifani nezinye izicucu ezivame ukusetshenziswa njengoba ivumelana nezimo kakhulu - futhi isetshenziswa esikhundleni senjoloba (engakwazi ukuphrintwa nge-3D) uma kudingeka ukuguquguquka. Isetshenziswa kakhulu ocingweni nasezimbozweni zokuzivikela. Ubulukhuni bungaba phakathi kuka-30 ~ 80shore A

Imibala: Mnyama, Mhlophe, Osobala

Okungcono kakhulu:

- Ibheka ukudala izingxenye eziphrintiwe ze-3D ezithambile eziguqukayo njengamakesi efoni, amakhava, njll

- Ifuna izingxenye eziphrintiwe ze-3D ezithambile kuye kweziqinile

Inayiloni

Inayiloni iwukwenziwa kwe-polymer ephrintiwe ye-3D eqinile, ehlala isikhathi eside, futhi evumelana nezimo futhi evame ukusetshenziselwa izingxenye ezisetshenziswa ekugcineni nokuhlola emithwalweni ephezulu. Izinto zokuphrinta zenayiloni 3D zivame ukusetshenziselwa ukwakha ama-prototype aqinile angahlolwa embonini, kanye nokudala izingxenye ezifana namagiya, amahinge, izikulufu, nezingxenye ezifanayo.

Imibala: I-SLS: Emhlophe, Emnyama, Eluhlaza MJF: Empunga, Emnyama

Okungcono kakhulu:

- Ama-prototypes asebenza kahle kakhulu embonini

- Izingxenye zokusebenza ezinhle njengezikulufi, amagiya namahinge

- Izingxenye ezimelana nomthelela lapho kukhethwa khona ukuguquguquka okuthile

I-Aluminium/Insimbi engagqwali

I-Aluminium iyisindi esingasindi, ihlala isikhathi eside, iqinile, futhi inezinto ezinhle ezishisayo.

Insimbi engagqwali inamandla aphezulu, i-ductility ephezulu, futhi imelana nokugqwala.

Imibala: Imvelo

Okungcono Kakhulu: Ukuqinisekiswa kokuhlolwa kwe-prototypes yamandla aphezulu

I-ABS

I-TPU

I-PLA

Inayiloni

Kusukela ku-Concept kuya ku-Reality

Ama-Prototypes asheshayo futhi aguquguqukayo

Izingxenye eziphrintiwe ze-3D ezisheshayo zilethwa ngokushesha okungamahora ayi-12.

Nqoba imikhawulo yejometri eyinkimbinkimbi

Inketho Yokuphrinta: FDM

Izinto: PLA, ABS

Isikhathi sokukhiqiza: Ngokushesha njengosuku olungu-1

Ukuqinisekisa Ukusebenza Kwekhwalithi Ephezulu

Thola ama-prototypes ekhwalithi ephezulu ukuze uhlolwe ukufaneleka. Amandla aqinile anendawo ebushelelezi

Inketho Yokuphrinta: SLA,SLS

Izinto: ABS-like, Nylon 12, Rubber-like

Isikhathi sokukhiqiza: 1-3days

Ukulethwa Okusheshayo Kwe-oda Eliphansi

Inketho engcono kakhulu ngokuphrinta kwe-3D ngesidingo esiphansi ngasinye okuyindlela eshibhile uma iqhathaniswa nezindleko zamathuluzi

Inketho Yokuphrinta: I-HP® Multi Jet Fusion (MJF)

Izinto: PA 12, PA 11

Isikhathi sokukhiqiza: Ngokushesha njengezinsuku ezi-3-4

Surface Finishing

Ukupenda kuyinketho evamile esetshenziswa izingxenye eziphrintiwe ze-3D ukuze zibonise izimonyo zombala. Ngaphezu kwalokho, ukudweba kungaba nomthelela wokuvikela ezingxenyeni.

Okubalulekile:

I-ABS, inayiloni, i-Aluminium, insimbi engagqwali, insimbi

Umbala:

Mnyama, noma iyiphi ikhodi ye-RAL noma inombolo ye-Pantone.

Ukwakheka:

Icwebezela, i-semi-gloss, isicaba, i-metallic, i-textured

Izicelo:

Imishini yasendlini, izingxenye zemoto, ama-aluminium extrusions

I-Powder coating iwuhlobo lokumboza olusetshenziswa ku-3D ephrintiwe ngempushana eyomile. Ngokungafani nopende oluvamile oluwuketshezi olulethwa nge-solvent ehwamukayo, ukumbozwa kwempushana kuvame ukusetshenziswa ngokwe-electrostatic bese kwelapheka lapho kushisa.

Izinto zokwakha:

I-ABS, i-Aluminium, insimbi engagqwali, insimbi

Imibala:

Mnyama, noma iyiphi ikhodi ye-RAL noma inombolo ye-Pantone.

Ukwakheka:

I-gloss noma i-semi-gloss

Izicelo:

Izingxenye zemoto, izinto zasendlini, ama-aluminium extrusions

Ukupholisha kuyinqubo yokudala indawo ebushelelezi futhi ecwebezelayo, inqubo ikhiqiza indawo enokuboniswa okubalulekile okukhethekile, kodwa kwezinye izinto ziyakwazi ukunciphisa ukubonakaliswa okusabalalisayo.

Izinto zokwakha:

I-ABS, inayiloni, i-Aluminium, ithusi, insimbi engagqwali, insimbi

Imibala:

N/A

Ukwakheka:

Iyacwebezela, Shiny

Izinhlobo:

Ukupholisha ngomshini, ukupholisha ngamakhemikhali

Izicelo:

Amalensi, ubucwebe, izingxenye zokuvala

Ukuqhunyiswa kobuhlalu kubangela indawo ebushelelezi ye-matte. Futhi kuyindlela ephumelelayo yokushelela okuthile ngaphambi kokufaka okokunamathela. Ukukhetha okuhle kokwelashwa kwendawo.

Izinto zokwakha:

I-ABS, i-Aluminium, ithusi, insimbi engagqwali, insimbi

Imibala:

N/A

Ukwakheka:

I-Matte

Umbandela:

Sa1, Sa2, Sa2.5, Sa3

Izicelo:

Kudingeka izingxenye zezimonyo

Isethembiso Sethu Sekhwalithi

Kuyini ukuphrinta kwe-3D

Mayelana nokuphrinta kwe-3D

Ukuphrinta kwe-3D noma ukukhiqiza okungeziwe kuyinqubo yokwenza izinto eziqinile ezinobukhulu obuthathu ukusuka kufayela ledijithali. Izinto zikhiqizwa ungqimba ngongqimba kusetshenziswa izinto ezahlukahlukene ezahlukahlukene kanye nobuchwepheshe bokunamathela kwesendlalelo

Izinzuzo zokuphrinta kwe-3D

1. Ukwehliswa kwezindleko: inzuzo ebalulekile yokuphrinta kwe-3D

2. Imfucuza encane: okuyingqayizivele yokwakha umkhiqizo ngemfucuza encane kakhulu, lokhu kubizwa ngokuthi ukukhiqiza okungeziwe, Nakuba izindlela ezivamile zizoba nemfucuza.

3. Yehlisa isikhathi: kuyinzuzo esobala futhi eqinile yokuphrinta kwe-3D, njengoba kuyinqubo esheshayo yokwenza ukuqinisekiswa kwe-prototype.

4. Ukwehliswa kwephutha: njengoba idizayini yakho ikhethwa, ingagoqelwa ngokuqondile kusofthiwe ukuze ulandele idatha yedizayini ukuze uphrinte isendlalelo esisodwa ngesendlalelo esisodwa, ngakho-ke kungabikho imanuwali ehilelekile phakathi nenqubo yokuphrinta.

5. Isidingo sokukhiqiza: Izindlela zendabuko zisebenzisa ukubumba noma ukusika, ukuphrinta kwe-3D akudingi noma yimaphi amathuluzi engeziwe angakusekela ngesidingo esiphansi sokukhiqiza.

Ngiyithola kanjani isiphetho esibushelelezi ku-3D ephrintiwe?

Ngokuvamile, silindele ukuba nombukiso ongcono obushelelezi ongcono onamasampula aphrintiwe e-3D ukuze sibonise lokho esingakusebenzisa futhi senze izingxenye zobuciko, kodwa kuza inselele enkulu lapho wenza izingxenye ngokuphrinta kwe-3D, khona-ke ungase uzibuze ukuthi singakwenza kanjani lokhu, bhekisisa izinyathelo zokufinyelela isiphetho esibushelelezi engxenyeni yakho ephrintiwe ye-3D khona-ke uzothola ukuthi kulula kakhulu kunalokho ongase ucabange ngakho:

01: Indlela Yokuphrinta Ekwesokudla: Khetha impahla eluhlaza efanele futhi usethe amapharamitha alungile ephrinta yakho ye-3D ezingxenyeni ozifisayo, kwakudinga onjiniyela abangochwepheshe ukwenza lokhu.

02: I-Sanding polishing: ukupholisha isihlabathi izingxenye eziphrintiwe ze-3D kulula kodwa kudinga ukugxila emininingwaneni ngesinyathelo ngesinyathelo ukusuka ku-100-1500 grit ukuze kufinyelelwe esiphetho esibushelelezi ngaphandle kwemigqa yokunyathela nanoma yikuphi ukuthungwa okumaholo, uma usuqedile lokho, indawo engaphezulu kufanele ishelele kakhulu.

03: I-Surface Electric corrosion: ingenziwa ezingxenyeni zensimbi eziphrintiwe ze-3D ezisebenzisa ukugqwala kukagesi ongaphezulu njenge-EDM ukuze kufezwe ukuqedwa okushelelayo kwekhwalithi ephezulu, njengokucwebezela njengesibuko.