Isevisi yemishini ye-CNC

Inqubo Etholakalayo Yemishini Ye-CNC

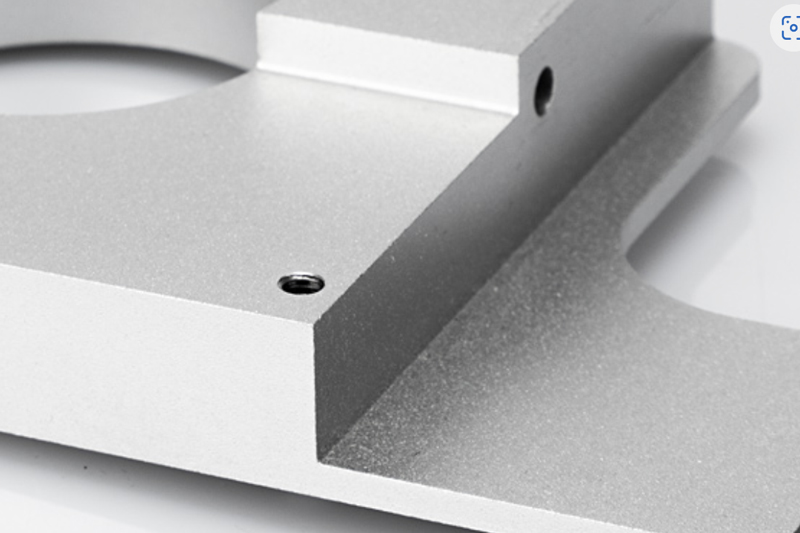

Isevisi yokugaya ye-CNC

Ngamasethi angaphezu kwama-50 wemishini engu-3, 4, kanye ne-5-axis CNC ukunikeza ukubekezelela okuphezulu kakhulu kufika ku-±0.0008″ (0.02 mm) izingxenye zokugaya ze-Precision CNC. Isitolo somshini esiku-inthanethi somshini we-prototype nokukhiqiza.

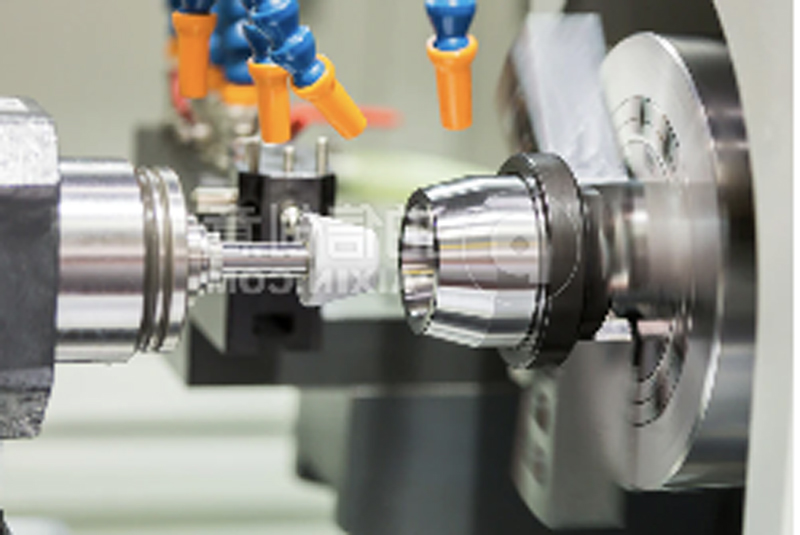

Isevisi yokuguqula i-CNC

I-80+ CNC Lathes kanye nezikhungo zokuphendula ze-CNC, zingahlinzeka ngezinsizakalo zokunemba zokunemba ezingabizi ngokuphendula okusheshayo. Iminyaka engu-15+ onjiniyela abangochwepheshe ukusekela ngemikhiqizo eyinkimbinkimbi.

Umshini Wokukhipha Ugesi(EDM)

Indlela yokwenza imishini engathinteki yezakhiwo ezintekenteke. izinhlobo ezimbili zezinqubo ze-Electrical Discharge Machining (EDM) esizinikezayo, i-Wire EDM kanye ne-Sinker EDM. Izinqubo ziwusizo ekusikeni amaphakethe ajulile nezici eziyinkimbinkimbi njengamagiya nezimbobo ezinokhiye.

CNC Machining Izicelo

Rapid Tooling

I-CNC machining iyisixazululo esiphelele sokwenza izinto ezilungiswayo noma isikhunta. I-CNC machining ingasika izinhlobonhlobo eziphezulu zezinto eziminyene ngokugcwele, ezihlala isikhathi eside njenge-aluminium 5052 nensimbi engagqwali.

I-Prototyping esheshayo

Ama-Prototypes azolunga osukwini olungu-1. Sinochwepheshe bemishini abangama-20+ ukusekela ama-prototypes asheshayo nasezingeni eliphezulu. Ama-alloys ensimbi athengekayo namapulasitiki angafakwa kuma-prototypes.

Ukukhiqiza Kokugcina

Ukubekezelela okuqinile kuze kufike ku-+/- 0.001”, izinketho zezinto ezibonakalayo eziqinisekisayo kanye nezinqubo ezihlukahlukene zokwelashwa kwendawo kwenza i-CNC ibe ubuchwepheshe obuhle kakhulu bezingxenye ezisetshenziswayo ekugcineni. Izinkulungwane zezingcezu zizolunga ngezinsuku.

I-CNC Machining Materials Selection----Metal

I-FCE izokusiza ukuthi uthole izinto ezihamba phambili ngokuya ngesidingo somkhiqizo kanye nokusetshenziswa. Khetha phakathi kwezinketho ezisheshayo nezingabizi kakhulu ukuze uthole okubalulekile.

·CNC Machining Aluminium Alloys

I-Aluminium 6061

I-Aluminium 5052

I-Aluminium 2024

I-Aluminium 6063

I-Aluminium 7050

I-Aluminium 7075

I-Aluminium MIC-6

·CNC Machining Copper Alloys

Ithusi 101

Ithusi C110

·CNC Machining Bronze Alloys

Ithusi C932

·CNC Machining Brass Alloys

Ithusi 260

Ithusi 360

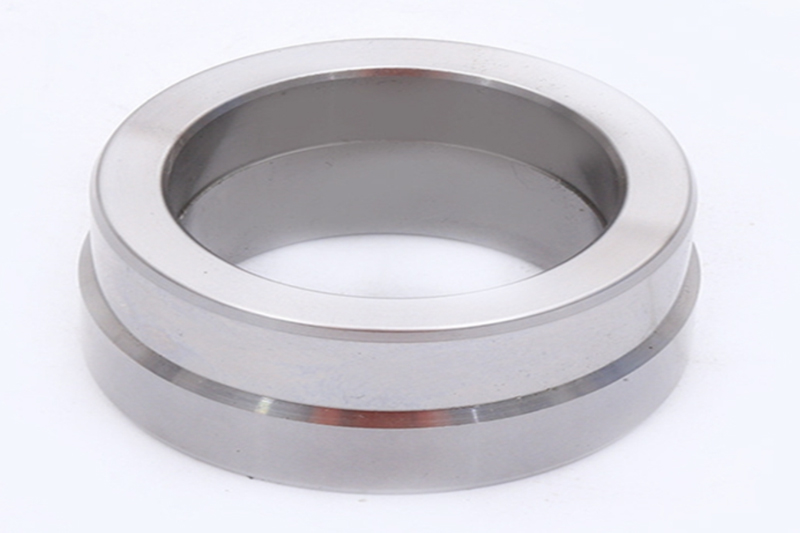

·CNC Machining Stainless Steel Alloys

I-Nitronic 60 (218 SS)

Insimbi engagqwali 15-5

Insimbi engagqwali 17-4

Insimbi engagqwali 18-8

Insimbi Engagqwali 303

Insimbi Engagqwali 316/316L

Insimbi Engagqwali 416

Insimbi Engagqwali 410

Insimbi Engagqwali 420

Insimbi Engagqwali 440C

· CNC Machining Steel Alloys

Insimbi 1018

Insimbi 1215

Insimbi 4130

Insimbi 4140

Insimbi 4140PH

Insimbi 4340

Insimbi A36

·CNC Machining Titanium Alloys

I-Titanium (iBanga lesi-2)

I-Titanium (iBanga lesi-5)

·CNC Machining Zinc Alloys

I-Zinc Alloy

I-CNC Machining Materials Selection---- Ipulasitiki

I-FCE izokusiza ukuthi uthole izinto ezihamba phambili ngokuya ngesidingo somkhiqizo kanye nokusetshenziswa. Khetha phakathi kwezinketho ezisheshayo nezingabizi kakhulu ukuze uthole okubalulekile.

·ABS

I-ABS yenziwa ngomshini kalula kusetshenziswa amasu omshini ajwayelekile, njengokujika, ukugaya, ukubhola nokusaha.

·Acrylic

Ipulasitiki efana nengilazi ecacile, ivame ukusetshenziselwa ukusetshenziswa ngaphandle. Izakhiwo ezinhle zokuguga.

·Delrin (Acetal)

I-Delrin inokumelana okuhle nomswakama, ukumelana nokugqokwa okuphezulu, kanye nokungqubuzana okuphansi.

·Garolite G10

I-G10 Iqinile, iyasebenziseka futhi ivalela ngogesi. Yenziwe nge-epoxy resin engashisi ilangabi eqiniswa yindwangu ye-fiberglass.

·HDPE

I-polyethylene ephezulu-density iyipulasitiki engazwani nomswakama kanye namakhemikhali enamandla omthelela omuhle. Okuvame ukusetshenziselwa izinhlelo zokusebenza zangaphandle, iziqukathi ezingangeni amanzi kanye nezimpawu.

Inayiloni 6/6

Inayiloni 6/6 yandisa amandla emishini, ukuqina, ukuzinza okuhle ngaphansi kokunikezwa kokushisa kanye/noma ukumelana namakhemikhali.

·PC (Polycarbonate)

I-PC inezakhiwo ezingcono kakhulu zemishini nesakhiwo. Isetshenziswa kabanzi kuzimoto, emkhathini, nakwezinye izinhlelo zokusebenza ezidinga ukuqina nokuzinza.

· I-PEEK

I-PEEK ivame ukusetshenziswa njengenye into engasindi yezingxenye zensimbi. Ngokuvamile isetshenziswa ekushiseni okuphezulu, izinhlelo zokusebenza ezinengcindezi ephezulu. I-PEEK imelana namakhemikhali, ukuguga, kanye nomswakama, inikeza amandla aqinile okuqina,

· I-Polypropylene

I-Polypropylene ukumelana namakhemikhali noma ukugqwala. Inezici ezinhle kakhulu zikagesi futhi imunca umswakama omncane noma awukho nhlobo. Ithwala imithwalo elula isikhathi eside emazingeni okushisa ahluka kakhulu.

·PTFE (Teflon)

I-PTFE idlula amapulasitiki amaningi uma kukhulunywa ngokumelana namakhemikhali nokusebenza emazingeni okushisa aphakeme. Imelana nezincibilikisi eziningi futhi iyisivikeli esingcono kakhulu sikagesi.

·UHMW PE

I-polyethylene enesisindo esiphezulu se-molecular. I-UHMW PE ayimumbi umswakama futhi inikeza inhlanganisela eyingqayizivele yokumelana nokuguga nokugqwala, ukumelana namakhemikhali aphezulu, ukungqubuzana okuphansi kwendawo, amandla omthelela aphezulu.

·PVC

I-PVC ivamise ukusetshenziswa ezindaweni ezichayeke oketshezini noma idinga ukufakwa kukagesi. Futhi ipulasitiki yokwenziwa imelana kakhulu namakhemikhali

I-CNC Machining Surface Iyaphela

Okujwayelekile (Okugayiwe)

Kuyinqubo esheshayo yokushintsha imishini. Inobushelelezi obungaphezulu obungu-3.2 μm (126 μin). Wonke amaphethelo acijile ayasuswa, futhi izingxenye ziyasuswa. Izimpawu zamathuluzi ziyabonakala.

I-Bead Blast

Ingxenye engaphezulu ishiywe inokubukeka okubushelelezi, okumatte

Idilika

Kuyinqubo esheshayo yokushintsha imishini. Inobushelelezi obungaphezulu obungu-3.2 μm (126 μin). Wonke amaphethelo acijile ayasuswa, futhi izingxenye ziyasuswa. Izimpawu zamathuluzi ziyabonakala.

I-Anodized

Izingxenye zingenziwa nge-anodized ngemibala eminingi ehlukene-Ecacile, emnyama, empunga, ebomvu, eluhlaza okwesibhakabhaka, egolide.

Passivation

Izingxenye zingagcotshwa ngemibala eminingi ehlukahlukene—emnyama, ecacile, ebomvu, nesagolide.

Ijazi Lempushana

Izingxenye zingagcotshwa ngemibala eminingi ehlukahlukene—emnyama, ecacile, ebomvu, nesagolide.

I-CNC Machining Design Guidelines

| Isici | Incazelo |

| Ama-fillet ekhoneni langaphakathi | Dizayina izibopho zangaphakathi zamakhona ukuze zibe ngu-0.020” - 0.050” zibe mkhulu kunosayizi wokubhoboza ojwayelekile werediya. Landela i-diameter ye-drill to deep ratio engu-1:6 (kunconyiwe1:4) njengesiqondiso serediya yekhona langaphakathi. |

| Izibopho zaphansi | Dizayina izibopho zaphansi ezincane kuneziqephu zekhoneni ukuze uvumele ithuluzi elifanayo ukusula izinto ngaphakathi. |

| Ama-Undercuts | Ngaso sonke isikhathi dweba ama-undercuts abe osayizi abajwayelekile futhi kude namakhona ukuze afinyeleleke ngethuluzi lokusika. |

| Ukujula kwembobo ethenjiwe/eluchungechunge | Nikeza imvume yethuluzi ngaphezu kancane kokushona kwembobo ethenjiwe ukuze uqinisekise imicu ephelele. |

| Inkimbinkimbi | Gcina inani lokusikeka okuncane libe lincane ukuze unciphise izindleko zokwenza imishini ye-CNC; klama kuphela ezicini ezidingekayo ukuze ulinganisele umsebenzi nobuhle. |

I-CNC Machining Tolerances

| Isici | Incazelo |

| Ubukhulu Bengxenye Usayizi | Izingxenye ezigayiwe zingafika ku-80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lamba izingxenye zifike ku-62” (1,575 mm) ubude no-32” (813 mm) ububanzi. |

| Isikhathi Esijwayelekile Sokuhola | 3 izinsuku zebhizinisi |

| Ukubekezelelana Okujwayelekile | Ukubekezelela ezinsimbi kuzogcinwa ku-+/- 0.005" (+/- 0.127 mm) ngokuvumelana ne-ISO 2768 ngaphandle kwalapho kucaciswe ngenye indlela. Ipulasitiki nezinhlanganisela kuzoba +/- 0.010”. |

| Precision Tolerances | I-FCE ingakhiqiza futhi ihlole ukubekezelelana okuqinile ngokwezicaciso zakho zokudweba okuhlanganisa nokubiza kwe-GD&T. |

| Ubuncane Besici Besici | 0.020” (0.50 mm). Lokhu kungase kuhluke kuye ngengxenye yejometri nezinto ezikhethiwe. |

| Imicu kanye nezimbobo ezithenjiwe | I-FCE ingakwazi ukufaka noma yimuphi usayizi wentambo ojwayelekile. Singakwazi futhi umshini imicu ngokwezifiso; lokhu kuzodinga ukubuyekezwa kwekhwothi mathupha. |

| Isimo somphetho | Amaphethelo acijile aphukile futhi akhishwe ngokuzenzakalela |

| I-Surface Qeda | Ukuqedwa okujwayelekile kunjengomshini: 125 Ra noma okungcono. Izinketho zokuqedela ezengeziwe zingacaciswa lapho uthola ikhotheshini. |

Isethembiso Sethu Sekhwalithi