Ku-Mold Labeling

Inqubo Etholakalayo Yemishini Ye-CNC

Ubungcweti Bobunjiniyela Nesiqondiso

Ithimba lobunjiniyela lizokusiza ekuthuthukiseni ukwakheka kwengxenye yokubumba, ukuhlola kwe-GD&T, ukukhetha kwezinto. I-100% iqinisekisa umkhiqizo ngokutholakala okuphezulu kokukhiqiza, ikhwalithi, ukulandeleka

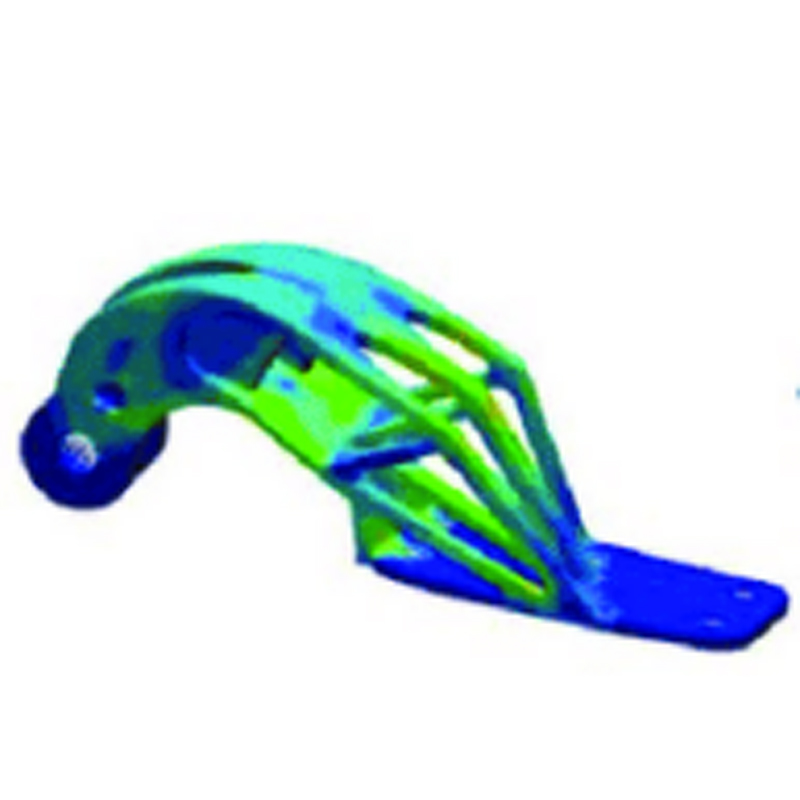

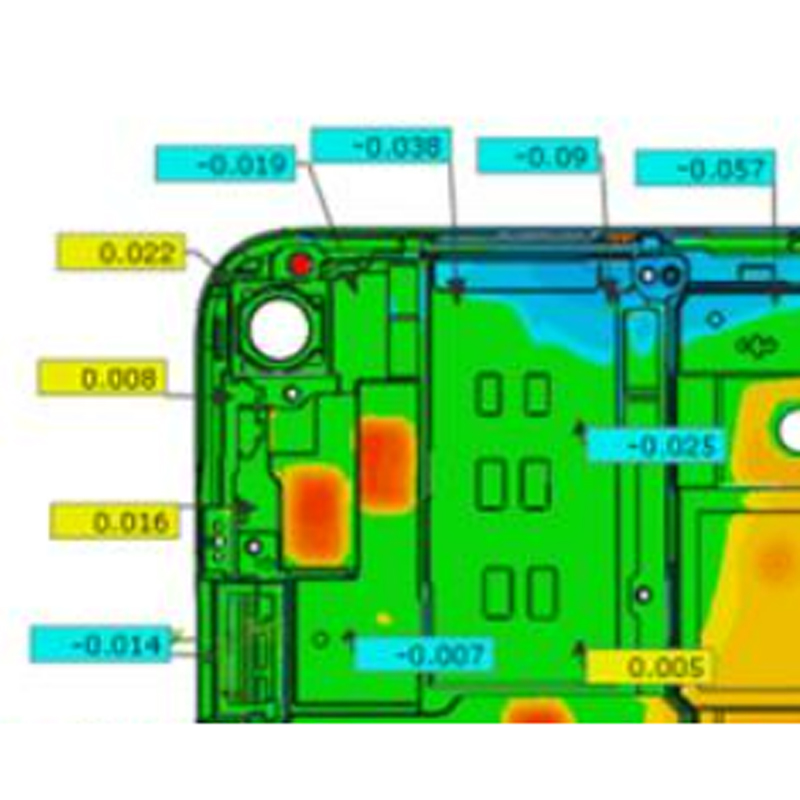

Ukulingisa ngaphambi kokusika insimbi

Ekuboneni ngakunye, sizosebenzisa ukugeleza kwesikhunta, i-Creo, i-Mastercam ukuze silingise inqubo yokubumba umjovo, inqubo yokwenza imishini, inqubo yokudweba ukubikezela inkinga ngaphambi kokwenza amasampula angokomzimba.

Idizayini Yomkhiqizo Eyinkimbinkimbi Yamukelwe

Sinezindawo eziphezulu zokukhiqiza umkhiqizo ekubunjweni komjovo, ukwenziwa kwemishini ye-CNC kanye nokwenza amashidi ensimbi. Okuvumela ukwakheka komkhiqizo okuyinkimbinkimbi, okunembayo okuphezulu

Enqubeni yasendlini

Ukwenza isikhunta somjovo, ukubumba komjovo kanye nenqubo yesibili yokuphrinta iphedi, ukugoba ukushisa, isitembu esishisayo, ukuhlanganisa konke kusendlini, ngakho-ke uzoba nezindleko eziphansi kakhulu nesikhathi sokuhola sokuthuthukiswa okuthembekile.

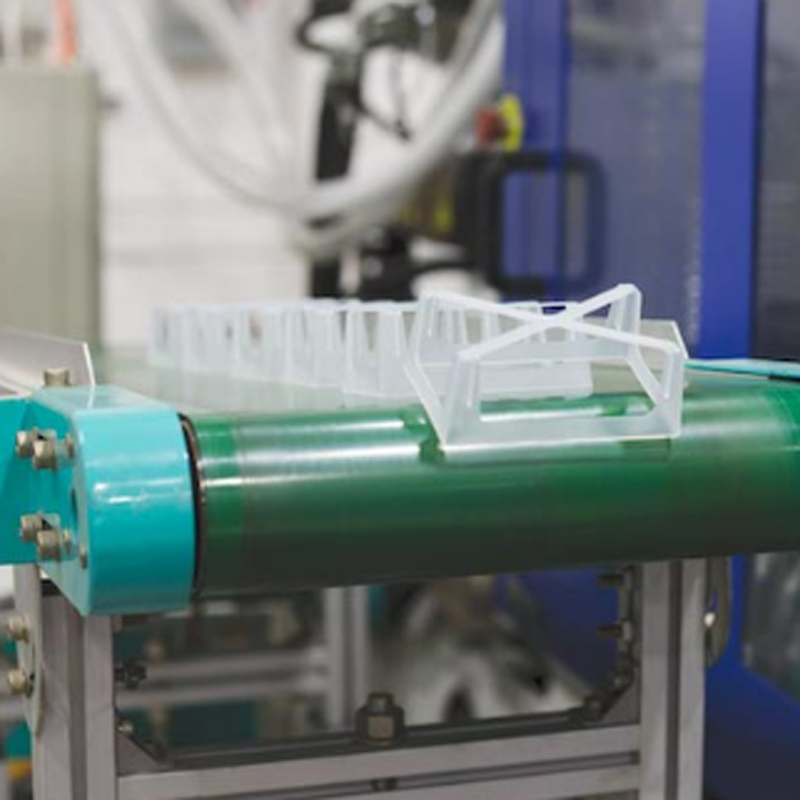

Ku-Mold Labeling

Ku-Mold Labeling (IML) kuyinqubo yokubumba umjovo lapho ukuhlobisa kwengxenye yepulasitiki, kusetshenziswa ilebula, kukhiqizwa phakathi nenqubo yomjovo wepulasitiki. Kalula nje, ilebula ephrintiwe ngaphambili ifakwa kusetshenziswa i-automation emgodini womjovo wesikhunta bese upulasitiki ujovwa phezu kwelebula. Lokhu kukhiqiza ingxenye yepulasitiki ehlotshisiwe / “enelebula” lapho ilebula ihlanganiswa unomphela engxenyeni ngokwayo.

Izinzuzo zamasu okulebula e-Rosti esikhumbeni afaka:

• Kufika ku-45% we-foil curvature (ukushona nobubanzi)

• Inqubo yamahhala eyomile nencibilikayo

• Amandla okuklama angenamkhawulo

• Ukushintsha kwedizayini okusheshayo

• Izithombe ezinokulungiswa okuphezulu

• Izindleko eziphansi, ikakhulukazi kumaphrojekthi wevolumu ephezulu

• Ukuzuza imiphumela engenakwenzeka ngobunye ubuchwepheshe

• Iqinile futhi iqinile ekugcineni okuhlanzekile kwemikhiqizo eqandisiwe neyefriji

• Ukuqeda ukumelana nokulimala

• Ukuqaphela imvelo

Izinzuzo ze-IML

Ezinye zezinzuzo zobuchwepheshe ze-IML zifaka:

• Qedela umhlobiso wengxenye ebunjiwe

• Ukuqina kwezithombe: Oyinki bavikelwa ifilimu ekwakhiweni kwendawo yesibili

• Imisebenzi yesibili ehlobene nomhlobiso wangemuva kokubumba iyaqedwa

• Ukuqedwa kwesidingo sezindawo zamalebula ahoxisiwe

• Amafilimu amaningi nezakhiwo ezitholakalayo ukuze zihlangabezane nezidingo zamakhasimende

• Kulula ukukhiqiza izinhlelo zokusebenza ezinemibala eminingi

• Amazinga aphansi e-scrap

• Ihlala isikhathi eside futhi ingaphazamiseki

• Ukulinganisa umbala ophakeme

• Ayikho indawo lapho ukungcola kungaqoqa khona

• Imibala engenamkhawulo iyatholakala

Kuhlelo Lokufaka Amalebula Kwesikhunta

Kuncike kakhulu emcabangweni wakho ukunquma ukuthi yimaphi amaphrojekthi angasebenzisa ukulebula okungaphakathi kwesikhunta, kodwa nanka amaphrojekthi aqhubekayo nazayo;

- izihlungi ze-tumbler ezomile, ukuze zizenzele inqubo yokuphakelayo

- ukumaka imijovo nezitsha

- izingxenye zokufaka amakhodi nokumaka embonini yezimoto

- ukwenza kube ngokwakho imikhiqizo yemboni yezemithi njll

- ukulandeleka kwemikhiqizo nge-RFID

- ukuhlobisa ngezinto ezingezona ezejwayelekile njengezindwangu

Uhlu lungenziwa lube lude kakhulu futhi ikusasa lizokhombisa okusha okungakazwiwa ngezinhlelo zokusebenza ezizokwenza ukukhiqizwa kungabizi futhi kusheshe, kuthuthukise ikhwalithi futhi kuthuthukise ukuphepha, ukulandeleka nokusatshalaliswa.

Kumpahla Yokulebula Isikhunta

Ukunamathela phakathi kwama-foil ahlukene kanye nezinto zokweqisa

| Izinto eziguquliwe | |||||||||||||||||

| I-ABS | I-ASA | EVA | PA6 | PA66 | I-PBT | PC | I-PEHD | I-PELD | I-PET | PMMA | I-POM | PP | PS-HI | SAN | I-TPU | ||

| Izinto ze-foil | I-ABS | ++ | + | + | + | + | − | − | + | + | − | − | ∗ | + | + | ||

| I-ASA | + | ++ | + | + | + | − | − | + | + | − | − | − | + | + | |||

| EVA | + | + | ++ | + | + | + | + | + | |||||||||

| PA6 | ++ | + | ∗ | ∗ | ∗ | ∗ | − | ∗ | − | + | + | ||||||

| PA66 | + | ++ | ∗ | ∗ | ∗ | ∗ | − | − | − | + | + | ||||||

| I-PBT | + | + | ∗ | ∗ | ++ | + | − | − | + | − | − | − | − | + | + | ||

| PC | + | + | ∗ | ∗ | + | ++ | − | − | + | + | − | − | − | + | + | ||

| I-PEHD | − | − | + | ∗ | ∗ | − | − | ++ | + | − | ∗ | ∗ | − | − | − | − | |

| I-PELD | − | − | + | ∗ | ∗ | − | − | + | ++ | − | ∗ | ∗ | + | − | − | − | |

| I-PET | + | + | + | + | − | − | + | − | − | − | + | ||||||

| PMMA | + | + | − | − | ∗ | ∗ | − | ++ | ∗ | − | + | ||||||

| I-POM | − | − | − | − | − | − | ∗ | ∗ | − | ++ | − | − | − | ||||

| PP | − | − | + | ∗ | − | − | − | − | + | ∗ | − | ++ | − | − | − | ||

| PS-HI | ∗ | − | + | − | − | − | − | − | − | − | − | − | − | ++ | − | − | |

| SAN | + | + | + | + | + | + | + | − | − | + | − | − | − | ++ | + | ||

| I-TPU | + | + | + | + | + | + | − | − | + | − | − | + | + | ||||

++ Ukunamathela okuhle kakhulu, + Ukunamathela okuhle, ∗ Ukunamathela okubuthakathaka, − Akukho ukunamathela.

I-EVA, i-Ethylene vinyl acetate; I-PA6, i-Polyamide 6; I-PA66, i-Polyamide 66; i-PBT, i-Polybutylene terephthalate; PEHD, Polyethylene high density; PELD, Polyethylene low density; I-POM, i-Polyoxymethylene; I-PS-HI, I-Polystyrene High Impact; I-SAN, i-Styrene Acrylonitrile; I-TPU, i-Thermoplastic polyurethane.

Amandla ahlobene we-IML vs. IMD izixazululo zokulebula

Ukuhlanganisa inqubo yokuhlobisa nenqubo yokubumba kwengeza ukuqina, kunciphisa izindleko zokukhiqiza futhi kudala ukuguquguquka komklamo.

Ukuqina

Imidwebo ayinakwenzeka ukususa ngaphandle kokucekela phansi ingxenye yepulasitiki futhi izohlala inempilo impilo yengxenye. Izinketho ziyatholakala zokuqina okuthuthukisiwe ezindaweni ezinokhahlo kanye nokumelana namakhemikhali.

Ukusebenza kahle kwezindleko

I-IML iqeda ukulebula kwangemuva kokubumba, ukuphatha nokugcina. Yehlisa i-inventory ye-WIP kanye nesikhathi esengeziwe esidingekayo sokuhlobisa ngemva kokukhiqizwa, endaweni noma ngaphandle kwesayithi.

Ukuvumelana nezimo

I-IML itholakala ngemibala eminingi eminingi, imiphumela, indlela yokwenza kanye nezinketho zezithombe futhi ingaphindaphinda ngisho nokubukeka okuyinselele okufana nensimbi engagqwali, okusanhlamvu kwezinkuni kanye ne-carbon fiber. Uma kudingeka isitifiketi se-UL, amasampula elebula ekwisikhunta ayahlolwa ngokuhambisana namazinga okuphepha afanayo asetshenziselwa ukuhlola amalebula azwela ukucindezela.